Article citation information:

Grega, R., Homišin, J., Krajňák, J., Urbanský, M.: Analysis of the

impact of flexible couplings on gearbox vibrations. Scientific Journal of Silesian University of Technology. Series

Transport. 2016, 91, 43-50.

ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.91.4.

Robert GREGA[1],

Jaroslav HOMIŠIN[2],

Jozef KRAJŇAK[3],

Matej URBANSKÝ[4]

ANALYSIS OF THE IMPACT OF FLEXIBLE COUPLINGS ON GEARBOX

VIBRATIONS

Summary. Dangerous vibrations of mechanical

systems’ components are causes of failures and reduction in service life, as

well lead to negative effects on the environment and the health of

operators. In order to reduce these unwanted vibrations, it is necessary to pay

attention to the proper design of components in mechanical systems. The aim of

this article is based on the experimental measurements and demonstration of the

effects of different types of flexible couplings on the size of vibration in a

gearbox that forms part of a mechanical system.

Keywords: flexible couplings, vibrations,

gearbox, mechanical system

1. INTRODUCTION

In

mechanical systems, in which gear mechanisms are classified, unwanted vibrations

can be observed, for example, as a consequence of improperly designed,

manufactured, assembled and operated mechanical systems [1], [2], [3]. The main

issue regarding the reduction of vibrations concerns an intense flow of

information throughout the process of designing, manufacturing, installing, operating

and diagnosing mechanical systems. Responsibility for a low level of vibrations

cannot be delegated to a single designer, but should be owned by a team of

professionals. The fulfilment of all targets to minimize vibrations is in the

interests of those involved at the technical, legislative and subjective level.

It is very important to properly associate the aforementioned fields of

interest with the cost, durability and environmental impact of the measures

taken [10], [11], [12].

Knowledge

of the basic sources of excitation of vibration is one of the prerequisites for

enabling a reduction in vibrations within mechanical systems. It should be

remembered that, in addition to the known vibration exciters in vibration

spectra, random vibrations may occur that we cannot prejudge in advance. Such

random vibrations, however, could be an important source of information about

the technical condition of the mechanical system concerned [6], [7], [8], [9].

Torsional

vibrations represent a specific type of vibration, which are caused by the

rotating components. By assembling machinery that produces torsional vibrations

into a mechanical system, torsional vibrations follow the direction of energy

flow and in turn become vibration exciters to other parts of the system. In

many cases, serious failures are behind the cause of sources other than torsional

vibrations. It is very important to pay attention to machines that produce

torsional vibrations in order to minimize the impact of torsional vibrations within

a mechanical system. A very appropriate solution for vibration reduction in mechanical

systems is properly designed flexible shaft coupling. With properly designed

flexible coupling can help mechanical systems achieve a minimum level of

vibrations by appropriately tuning the revolutions produced by all members of

the system. In our case, the interest is directed to a gearbox, which forms

part of the examined mechanical system. Based on experimental measurements, we prove

the effect of different types of flexible couplings on the size of gearbox

vibration. In turn, we demonstrate the importance of appropriately tuning the mechanical

system using flexible coupling [4], [5].

2. EXPERIMENT DESCRIPTION

The experiment, which aimed to

demonstrate the impact of the flexible couplings on the size of gearbox

vibrations, was realized using the mechanical systems shown in Fig. 1. The

aforementioned mechanical system consisted of a torsional oscillation exciter,

which was a three-cylinder compressor. The compressor was driven by an

electromotor with the possibility of variable speed control. The examined

gearbox was included in the mechanical system between the compressor and the electromotor.

It was an auxiliary gearbox with the gear ratio i=1, as used in automotive drive.

The mechanical systems included other components necessary for diagnosing the

mechanical system.

The flexible couplings, which were used

during measurements, were included in sequence between the gearbox and the compressor.

Four types of coupling (shown in Fig. 2 to Fig. 5 inclusive) were examined:

pneumatic flexible coupling, Hardy coupling, Periflex coupling and claw

coupling.

Fig. 1 Scheme of the mechanical system

Fig. 2 Pneumatic flexible

coupling

Fig. 3 Hardy coupling

Fig. 4 Periflex coupling

Fig. 5 Claw coupling

3. EXPERIMENTAL MEASUREMENT RESULTS

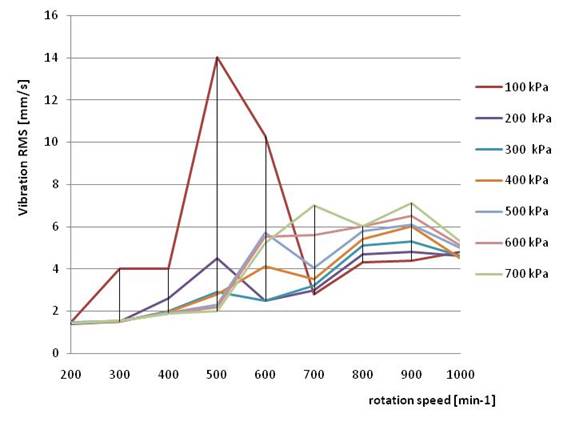

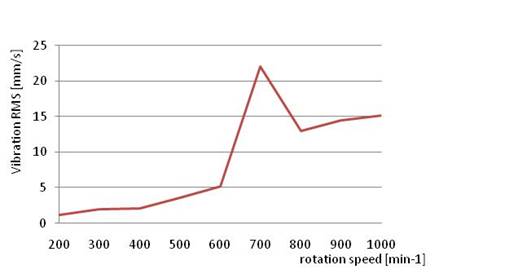

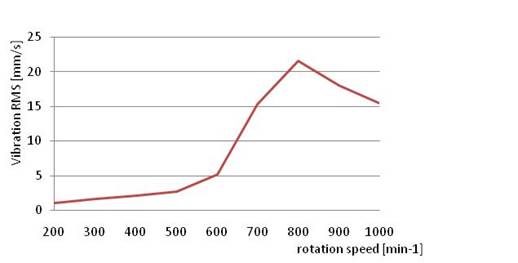

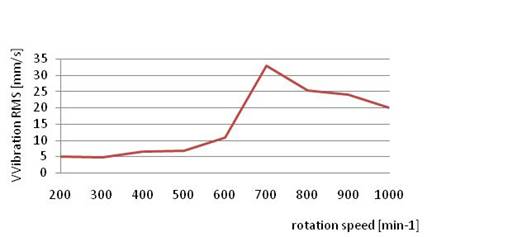

The experiments were carried out in an operating mode with a rotation

speed between 200 min-1 and 1,000 min-1. In this

operating mode, the values of vibrations on the gearbox were obtained. The measured

value of the monitored vibrations, which is known as RMS, is regarded as an

effective value of vibration speed. In the case of using pneumatic flexible

coupling to measure vibration values, air pressure between 100 kPa and 700 kPa,

in terms of pneumatic elements of coupling, were applied. In Fig. 6 to Fig. 9

inclusive, diagrams have been constructed based on the measurements of RMS on

the gearbox. As can be seen from the courses of RMS, the maximum value of the

vibration in each case is at a speed between 500 min-1 and 800 min-1.

This maximum value of RMS corresponds to the speed value when the mechanical system

starts to resonate from the main exciter’s harmonic component in the

compressor.

Fig. 6 Measured value of pneumatic flexible coupling

Fig. 7 Measured value of Hardy

coupling

Fig. 8 Measured value of Periflex

coupling

Fig. 9 Measured value of claw

coupling

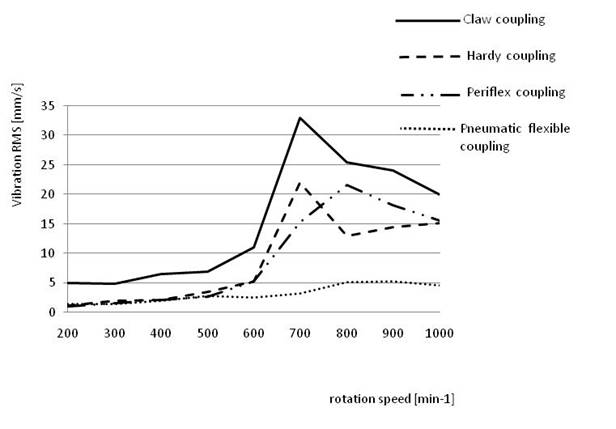

4. CONCLUSION

Following the mutual

comparison of the individual values of vibrations obtained from the measurements,

we can state that, in the current case regarding all operating speeds of the

mechanical system, the lowest vibration levels in a gearbox are achieved using pneumatic

flexible couplings with a pressure of 300 kPa in their pneumatic flexible

elements.

Fig. 10 presents all

RMS courses of each of the used couplings. The RMS course, which uses pneumatic

flexible coupling, represents the line with a value of air pressure equal to 300

kPa. As stated in this figure, we can observe that the size of vibration

involving pneumatic flexible coupling equates to less than 700% in comparison

with other couplings, especially in the area of resonance of

the mechanical system. The aforementioned target detections, therefore, represent

sufficient grounds to present our proposals for an appropriate coupling design

for any mechanical system. In particular, the suitability of selected

flexible coupling can significantly protect individual parts of

the mechanical system and thus increase their durability, as well as

reduce their failure rate.

Fig. 10 Measured value of all used

couplings

References

1.

Grega

R. et al. 2015 „The chances for reduction of vibrations in mechanical system

with low-emission ships combustion engines”. International Journal of Maritime

Engineering 157 (A4): 235-240. ISSN: 1479-8751.

2.

Baran P., R. Grega.

2015. „Comparison of dynamic properties of dual mass flywheel”. Diagnostyka

16(1): 29-33. ISSN: 1641-6414.

3.

Medvecká-Beňová

S., M. Mantič, R. Grega. 2014. „The stress

analysis in dangerous section of gear teeth”. Applied Mechanics

and Materials 611: 279-283.

ISSN: 1660-9336.

4.

Homišin J. 2013. „New ways of controlling dangerous torsional

vibration in mechanical systems”. Transactions on Electrical Engineering 2(3):

70-76.

ISSN: 1805-3386.

5.

Homišin J., P. Kaššay, P. Čopan. 2014. „Possibility of torsional

vibration extremal control”. Diagnostyka

15(2): 7-12. ISSN: 1641-6414.

6.

Vaško

M., B. Leitner, M. Sága. 2010. „Computational fatigue

damage prediction of the lorry frames under random excitation”. Communications

12(4): 62–67.

ISSN: 1335-4205.

7.

Sága M., P. Kopas,

M. Vaško. 2010. „Some computational aspects of vehicle shell frames

optimization subjected to fatigue life”. Communications 12(4): 73-79.

ISSN: 1335-4205.

8.

Konieczny Ł., R.

Burdzik, J. Warczek, P. Czech, G. Wojnar, J. Młyńczak. 2015. „Determination of the effect of tire stiffness on wheel accelerations by

the forced vibration test method”. Journal of Vibroengineering 17(8):

4469-4477.

ISSN: 1392-8716.

9.

Dekys

V., A. Sapietova, O. Stevka. 2013. „Understanding of the

dynamical properties of machines based on the interpretation of spectral

measurement and FRF”.

In 51st International

Scientific Conference on ”Experimental Stress analysis”: 106-112. Litomerice, Czech Republic. 11-13 June

2013.

10.

Jakubovičová L., P. Zavadinka, J. Jakubovič. 2016. „Transport duty cycle measurement of hybrid

drive unit for mixing drum”. Advances in

Intelligent Systems and Computing 393: 219-224. Berlin: Springer Verlag. ISSN:

21945357.

11.

Wojnar G., P. Czech, P. Folęga. 2014. „Problem with diagnosing local faults of gearboxes on the basis of vibration

signal”. Transactions of the Universities

of Košice 2: 95-100. ISSN: 1335-2334.

12.

Czech

P., G. Wojnar, J. Warczek. 2014. „Diagnosing of car engine fuel injectors

damage using bi-spectral analysis and radial basis function.” Logistyka 3: 1,181-1,187.

ISSN: 1231-5478.

This paper was written under the framework of Grant

Project VEGA: “1/0688/12 – Research on and application of a universal

regulation system in order to master the source of mechanical systems’

excitation”.

Received 21.11.2015; accepted in revised form 11.04.2016

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License