Article citation information:

Drewniak, J., Garlicka, P., Kolber, A. Design for the bi-planetary gear

train. Scientific Journal of Silesian

University of Technology. Series Transport. 2016, 91, 5-17. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.91.1.

Józef DREWNIAK[1],

Paulina GARLICKA[2],

Aleksandra KOLBER[3]

DESIGN FOR A BI-PLANETARY GEAR

TRAIN

Summary. The

article presents the design for a bi-planetary gear train. The project

description is supplemented with calculations of kinematics, statics and meshing

efficiency of the gear wheels included in the gear train. Excluded are calculations

of strength and geometry of gears, shaft and rolling bearing, since they are

similar to classical calculations for planetary gears. An assembly drawing in

2D and assembly drawings in 3D of the designed bi-planetary gear train are also

shown. This gear train will form the main element of the research in hand.

Keywords: bi-planetary gear train, transmission

ratio, meshing efficiency

1. INTRODUCTION

The structural diagram of a bi-planetary

gear train, or double planetary gear train, is shown in Fig. 1a and Fig. 2

[1]. It consists of a main planetary gear set and an internal planetary gear

set, which is known as an internal satellite system. The main planetary gear

set comprises sun gear 1, satellites 2 and 6, external carrier arm h and ring

gear 7, which is fastened to the frame, while the internal satellite system comprises

sun gear 3, satellites 4 with internal carrier arm H, and ring gear 5, which is

fastened to carrier arm h. In the bi-planetary gear train, the role

of second toothed satellite 6 (Fig. 1b) fulfils the needs of the planetary

gear train, known as the internal satellite system, with carrier arm H. H

drives planetary gear 6, which already belongs to the main gear set. At

the same time, rim gear 5 drives carrier arm h of the main planetary gear

set.

Fig. 1. Kinematic

diagrams of the bi-planetary and planetary gear trains [1]

A characteristic feature of this

gear train is that the satellites within the satellite mechanism rotate around

three axes – those of its own central planetary gear set and the main central bi-planetary

gear train. This particular property of bi-planetary gear train is mainly used

in face milling cutters for combined mining.

2. DESIGN CALCULATIONS

2.1. Kinematic diagram of the gear

The structure of the transmission is

selected depending on the kinematic ratio. The values of output torque are

equal to ![]() and

and ![]() , respectively, when the value of input revolution is equal

to

, respectively, when the value of input revolution is equal

to ![]() .

.

For the required range of output

speed ![]() , the mean transmission ratio and the acceptable range of

ratios are:

, the mean transmission ratio and the acceptable range of

ratios are:

![]() , (1)

, (1)

![]() .

(2)

.

(2)

On basis that the demands correspond

to the planetary gear, the kinematic diagram, as shown in Fig. 2, is according

to [2, 3, 9].

This gear comprises the inner transmission

(satellite planetary mechanism) of 3, 4, 5, H and of the outer transmission of 1,

2, 6, 7, h.

The degree of mobility of the

transmission is:

![]() (3)

(3)

where ![]() ( number of moving parts);

( number of moving parts); ![]() (number of pairs of 5-class (arm h on the right is oversized

or redundant)); and

(number of pairs of 5-class (arm h on the right is oversized

or redundant)); and![]() (number of pairs 4-class (engagement of teeth, counted only

once)).

(number of pairs 4-class (engagement of teeth, counted only

once)).

Fig. 2. Kinematic diagram of the bi-planetary

gear train

As the degree of mobility is ![]() , only one value of a speed output or input is needed to

determine the speed of each of the transmission components.

, only one value of a speed output or input is needed to

determine the speed of each of the transmission components.

2.2. Gear transmission ratio

According to the definition of the

kinematic gear ratio, ![]() (from pinion 1 to arm

(from pinion 1 to arm ![]() , when wheel 7 is fixed) is equal to [1, 3, 4, 5, 6, 7]:

, when wheel 7 is fixed) is equal to [1, 3, 4, 5, 6, 7]:

,

(4)

,

(4)

where ![]() (the rotational speed

of pinion 1 or input rotational speed of transmission) and

(the rotational speed

of pinion 1 or input rotational speed of transmission) and ![]() (the rotational speed

of arm

(the rotational speed

of arm ![]() , that is, the transmission output rotational speed) (Fig. 1).

In order to determine the kinematic ratio,

, that is, the transmission output rotational speed) (Fig. 1).

In order to determine the kinematic ratio, ![]() must first determine

the base ratio of the inner transmission, assuming that

the whole planetary gear rotational speed is equal to

must first determine

the base ratio of the inner transmission, assuming that

the whole planetary gear rotational speed is equal to ![]() (that is, to consider

the kinematics of planetary transmission in relation to arm

(that is, to consider

the kinematics of planetary transmission in relation to arm ![]() ). Then, the relative rotational speed of each wheel gear is equal

to

). Then, the relative rotational speed of each wheel gear is equal

to ![]() (

(![]() ) at the same time that

) at the same time that ![]() and

and ![]() (because

(because ![]() and

and ![]() ).

).

Similarly, the relative rotational speed

of inner arm H, in relation to external arm h, is ![]() . The basic kinematic ratio of the inner transmission, which consists

of wheels 3, 4, 5 and arm H with known relative speed

. The basic kinematic ratio of the inner transmission, which consists

of wheels 3, 4, 5 and arm H with known relative speed ![]() ,

, ![]() ,

, ![]() and

and ![]() , can be determined using the Willis formula (5) and

expression (6) for the transmission ratio of wheels 3, 4 and 5, in relation to

arm H as a function of the number of teeth (such as for the gears with

fixed axes) [1]:

, can be determined using the Willis formula (5) and

expression (6) for the transmission ratio of wheels 3, 4 and 5, in relation to

arm H as a function of the number of teeth (such as for the gears with

fixed axes) [1]:

![]() (5)

(5)

(6)

(6)

Hence:

![]() ,

(7)

,

(7)

because ![]() .

.

To calculate the requested transmission

ratio of the bi-planetary gear train, it is firstly

necessary to determine unknown relative rotational speeds ![]() and

and ![]() using formula (7)

above, as a function of

using formula (7)

above, as a function of ![]() (9) and

(9) and ![]() of the two conditions

on the gear ratios

of the two conditions

on the gear ratios ![]() (8) (the ratio from arm

H to wheel 7) and

(8) (the ratio from arm

H to wheel 7) and ![]() (10) (the ratio from

wheel 3 to wheel 1):

(10) (the ratio from

wheel 3 to wheel 1):

![]() , (8)

, (8)

Hence

![]() , (9)

, (9)

because ![]() .

.

Similarly,

![]() , (10)

, (10)

Hence

![]() , (11)

, (11)

because ![]() and

and ![]() .

.

Thus, after the subsequent

transformations, the quotient of the number of teeth ![]() , according to formula (7), takes the following form (12):

, according to formula (7), takes the following form (12):

. (12)

. (12)

Hence the formula for the ratio of

the bi-planetary gear train (4) is as follows:

(13)

(13)

The required value of the ratio

obtained for the numbers of teeth of the bi-planetary gear train – namely,![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() , is due to the following:

, is due to the following:

![]() , (14)

, (14)

That is, ![]() .

.

The actual

value of the output speed is ![]() .

.

2.3. Engagement efficiency of the transmission

Determining the efficiency of the

gear train only takes into consideration the losses incurred due to friction in

the gear engagements, i.e., it does not include the friction that occurs

between the bearings and the resistance of the splashing oil. Thus, according

to formula (15), the efficiency of the designed bi-planetary gear train only depends

on the base kinematic ratio ![]() of the transmission

and the base efficiency

of the transmission

and the base efficiency ![]() [1, 6, 7]:

[1, 6, 7]:

.

(15)

.

(15)

The base efficiency is determined in

relation to the serial sequence composed of the pair of wheels 1 and 2, planet

gears 3, 4 and 5, and the last pair of wheels 6 and 7:

![]() .

(16)

.

(16)

The efficiency of the pair of outer

wheels 1 and 2, when considered in motion relative to arm h, is determined by the

following known formula [3, 6]:

(17)

(17)

A similar formula determines the

efficiency of the pair of inner wheels 6 and 7, when considered in motion

relative to arm h [2, 3, 5, 6]:

.

(18)

.

(18)

The base efficiency for the internal

epicyclic gearing of 3, 4, 5 and H is determined by the following formula

[2, 3, 5, 6]:

,

(19)

,

(19)

where ![]() (see formula (7)) and

(see formula (7)) and ![]() are the base transmission ratio and the base efficiency of

the inner epicyclic transmission of 3, 4, 5 and H, respectively:

are the base transmission ratio and the base efficiency of

the inner epicyclic transmission of 3, 4, 5 and H, respectively:

![]() (20)

(20)

where![]() (base efficiency of wheels 3 and 4).

(base efficiency of wheels 3 and 4).

,

(21)

,

(21)

where![]() (base efficiency of wheels 4 and 5).

(base efficiency of wheels 4 and 5).

.

(22)

.

(22)

Component values of the base efficiency

for the assumed value of the coefficient of friction in engagement ![]() are:

are:

![]() ,

, ![]()

![]() ,

, ![]() ,

,

![]() ,

, ![]() ,

, ![]() .

.

Thus, the efficiency of the

planetary gear is:

, (23)

, (23)

because:

![]()

And:

![]() .

.

The value of efficiency of the bi-planetary

gear unit is similar to the value of efficiency of the three-axes non-planetary

gear train (![]() ), although it is greater than the efficiency value of the

planetary gear, even when the transmission ratio is of less value.

), although it is greater than the efficiency value of the

planetary gear, even when the transmission ratio is of less value.

2.4. Forces acting on the spur gear teeth

According to the principle of the operation

of the bi-planetary gear train, the output torque ![]() consists of three

components:

consists of three

components:

a) Torque ![]() generated by

generated by ![]() satellite 2 [1, 2]:

satellite 2 [1, 2]:

![]() ,

(24)

,

(24)

where ![]() (the force acting on

the axis of satellite 2) (Fig. 3);

(the force acting on

the axis of satellite 2) (Fig. 3); ![]() ,

, ![]() (the pitch radiuses of sun gear 3 and the satellite 2)’; and

(the pitch radiuses of sun gear 3 and the satellite 2)’; and ![]() (the radius of carrier arm h).

(the radius of carrier arm h).

Fig. 3. The forces acting during the engagement

of gears 1, 2, 3 and on left arm h

b) Torque ![]() generated by

generated by![]() rim gear wheel 5 (Fig. 3, Fig. 4):

rim gear wheel 5 (Fig. 3, Fig. 4):

![]() , (25)

, (25)

where ![]() ,

, ![]() (the pitch radiuses of

sun gear 3 and rim gear 5); and

(the pitch radiuses of

sun gear 3 and rim gear 5); and ![]() (the circumferential

force acting on gear 5).

(the circumferential

force acting on gear 5).

c) Torque ![]() generated by

generated by![]() carrier arm H and satellite 6 (Fig. 5):

carrier arm H and satellite 6 (Fig. 5):

![]() , (26)

, (26)

where![]() (the pitch radius of satellite 6); and

(the pitch radius of satellite 6); and ![]() (the force acting on

the axis of satellite 6).

(the force acting on

the axis of satellite 6).

Fig. 4. The forces acting during the engagement

of gears 3, 4, 5 and on arm H

Fig. 5. The forces acting during the engagement

of gears 6, 7 and on right arm h

As such, total output torque ![]() is equal to:

is equal to:

![]() . (27)

. (27)

Total output torque ![]() , with regard to engagement efficiency

, with regard to engagement efficiency ![]() , is equal to:

, is equal to:

![]() .

(28)

.

(28)

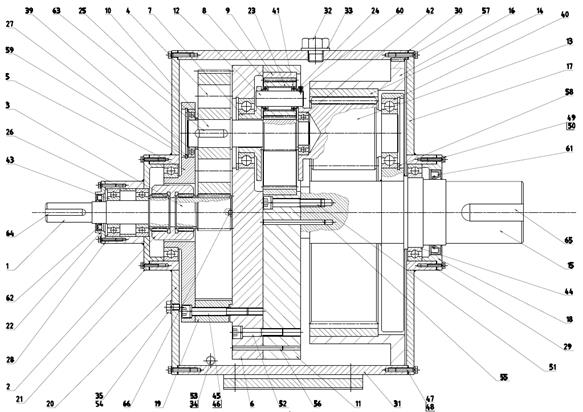

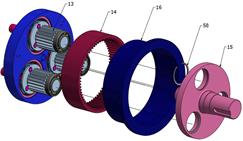

3. DESIGN BI-PLANETARY GEAR TRAIN

3.1. Description of the gear train

As previously mentioned in this

paper, the bi-planetary gear train consists of two planetary drive systems,

i.e., the outer gear set, also known as the main gear set, and the inner gear

set, which is known as a satellite planetary system. The main planetary gear

set consists of sun gear 3, which meshes with the three satellites 4 mounted on

three shafts, namely, pinions 10 of the satellite planetary system (Fig. 6). Pinions

10 represent the sun gear of the planetary satellite system. It drives the three

satellites 8, which are still engaged with the gear wheel due to internal teeth

9 being fitted to one of the three holes of arm 11. Each satellite is mounted

rotationally on axle 12, on which is supported one of the three internal arms H

(according to Fig. 1). Each arm H is a part of second satellite 13, which

already belongs to the main gear set.

Fig. 6. Assembly engineering drawing

of the bi-planetary gear train

Satellite

13 is meshed with fixed internal gear wheel 14 and internally mounted on the

right side of the hole in arm 11 of output shaft 15. Power is transmitted from

the electric motor via shaft 1 and clutch 2 to sun gear 3, which is

engaged with the three satellites 4 mounted on shaft 10 that transmits part of

the torque along intermediate arm 11, then along output shaft 15, while the

rest of the power is transmitted through gear wheel 9 to arm 11, then through

internal arm 7 (satellite 13) to right arm 11.

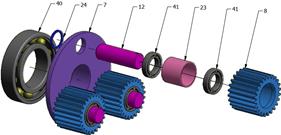

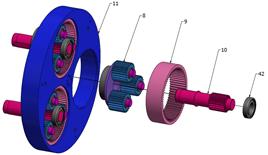

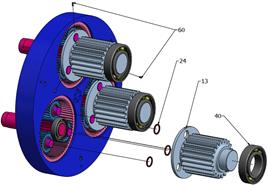

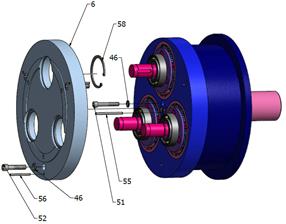

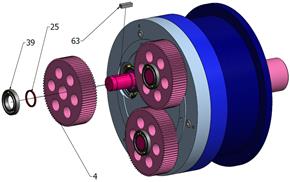

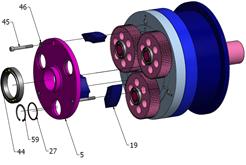

3.2. The order of the assembly

of the bi-planetary gear train elements

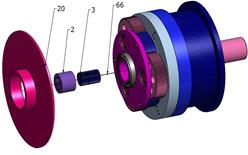

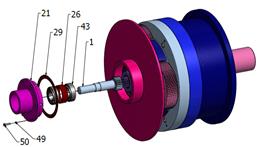

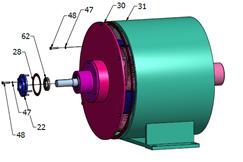

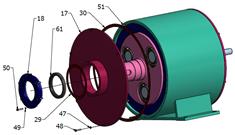

Engineering drawings of the assembly

sequence, which allow for checking the correctness of the designed bi-planetary

gear trains (Fig. 6) in terms of mounting options and possibly assessing its

degree of difficulty, are included in Table 1.

Tab. 1.

Engineering drawings of the assembly

sequence

|

a)

|

b)

|

|

c)

|

d)

|

|

e)

|

f)

|

|

g)

|

h)

|

|

i)

|

j)

|

|

k)

|

Note: not shown is the sequence of

the assembly of simple elements, such as oil filler plugs, oil level and oil

drain plug. |

4. CONCLUSION

This paper presents the design of a bi-planetary

gear train together with the calculation of the kinematics, statics and

meshing efficiency of gear wheels. Omitted from the calculation are the geometry

and strength of gears, shafts and rolling bearings, as these are recognized as

being typical design calculations. 3D drawings of the order of assembly

components have confirmed the correctness of the design of the bi-planetary

gear train. The designed planetary gear is constructed as a prototype for transmission

to the test bench in a laboratory for fundamental machine design. The main aim

of this study is in comparing the dynamics of the transmission between fastened

rim wheel 14 and the solution, when wheel 14 is suspended flexibly from the

coupling gear (variant II of the solution).

References

1.

Cyplakow

Ju.S. 1968. Biplanetarnye mechanizmy.

[In Russian: Bi-planetary Mechanisms].

Moscow: Mas’inostroenie.

2.

Drewniak J. 2000. Zbiór zadań z PKM III. [In Polish: The Set of Tasks from

PKM III]. Bielsko-Biała: ATH.

3.

Kudriawcew

W.N., Ju.N. Kirdiaszew (red.). 1977. Planetarnye

peredaczi. [In Russian: Planetary Peredaktsi].

Leningrad: Mas’inostroenie.

4.

Looman

J. 1988. Zahnradgetriebe. [In German:

Gear Transmission]. Berlin:

Springer-Verlag.

5.

Mueller

H.W. 1971. Die Umlaufgetriebe. [In German: The Epicyclic Gear]. Berlin: Springer Verlag.

6.

Mueller L., A. Wilk. 1996. Zębate przekładnie

obiegowe. [In

Polish: Toothed Planetary Gears]. Warsaw:

PWN.

7.

Rudenko W.N. 1980. Planetarnye i wolnowye

peredaci. [In

Russian: Planetary and Wave Transmission].

Moscow: Mas’inostroenie.

8.

Homišin J. 2008. Dostrajanie układów mechanicznych drgających skrętnie przy pomocy sprzęgieł

pneumatycznych: kompendium wyników pracy naukowo-badawczych. [In Polish: Tuning Torsionally Vibrating Mechanical Systems

using Pneumatic Couplings: A Compendium of Performance Research]. Bielsko-Biała:

ATH.

ISBN: 978-83-60714-55-3.

9.

Homišin

J., P. Kaššay, P. 2009. „Comparison of tuning in shipping system using pneumatic tuners of

torsional oscillations”. Machine modeling and simulations:

147-154. ISBN 978-80-89276-18-9.

10.

Grega

R., J. Krajňák. 2012. „The pneumatic dual-mass flywheel”. Scientific Journal of Silesian University of

Technology. Series Transport 76: 19-24. ISSN: 0209-3324.

11.

Grega

R. et al. 2015 „The chances for reduction of vibrations in mechanical system

with low-emission ships combustion engines”. International Journal of Maritime

Engineering 157 (A4): 235-240. ISSN 1479-8751.

12.

Homišin

J., P. Kaššay, M. Urbanský. 2011. „High-flexibility characteristics of

pneumatic flexible shaft couplings”. Pneumatyka 79(2): 26-29. ISSN 1426-6644.

13.

Medvecká-Beňová

S., J. Krajňák. 2015. „Modifications to a gearbox to increase the performance

of a winding machine for steel sheets.” IT-strojár: 1-3.

ISSN 1338-0761.

14.

Bigoš

P., J. Kuľka, M. Mantič, M. Kopas. 2015. „Comparison of local stress values

obtained by two measuring methods on a blast furnace shell”. Metalurgija

54(1):

101-104. ISSN 0543-5846.

15.

Grega

R., J. Krajňák. 2013. „The application of pneumatic flexible coupling in a conveyor drive”. Technológ

5(4): 51-54. ISSN 1337-8996.

16.

Medvecká-Beňová

S., J. Vojtková. 2014. „Application of an asymmetric profile in gearings with eccentric gears”. Scientific Journal of Silesian University of

Technology. Series Transport 85: 89-93. ISSN: 0209-3324.

17.

Kuľka

J., M. Mantič. 2014 „Effect of operational condition changes on the durability of the rope

for pusher of circular wagon tipper”. Applied

Mechanics and Materials 683: 28-32. ISSN 1660-9336.

18.

Homišin

J., M. Urbanský. 2015. „Partial results of extremal control of mobile mechanical system”. Diagnostyka 16(1): 35-39. ISSN

1641-6414.

Received 20.12.2015;

accepted in revised form 27.04.2016

![]()

Scientific Journal of

Silesian University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License