Article citation info:

Kolarič, D., Kolarič, M. Example of flow modelling characteristics in diesel engine nozzle. Scientific Journal of Silesian University of Technology. Series Transport. 2016, 90, 123-135. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2016.90.11.

Dušan KOLARIČ[1], Marko KOLARIČ[2]

EXAMPLE OF FLOW MODELLING CHARACTERISTICS IN DIESEL ENGINE NOZZLE

Summary. Modern transport is still based on

vehicles powered by internal combustion engines. Due to stricter ecological

requirements, the designers of engines are continually challenged to develop

more environmentally friendly engines with the same power and performance.

Unfortunately, there are not any significant novelties and innovations

available at present which could significantly change the current direction of

the development of this type of propulsion machines. That is why the existing

ones should be continually developed and improved or optimized their

performance. By optimizing, we tend to minimize fuel consumption and lower

exhaust emissions in order to meet the norms defined by standards (i.e.

Euro standards). Those propulsion engines are actually developed to such extent

that our current thinking will not be able to change their basic functionality,

but possible opportunities for improvement, especially the improvement of

individual components, could be introduced. The latter is possible by

computational fluid dynamics (CFD) which can relatively quickly and

inexpensively produce calculations prior to prototyping and implementation of

accurate measurements on the prototype. This is especially useful in early

stages of development or at optimization of dimensional small parts of the

object where the physical execution of measurements is impossible or very

difficult. With advances of computational fluid dynamics, the studies on the nozzles

and outlet channel injectors have been relieved. Recently, the observation

and better understanding of the flow in nozzles at large pressure and high

velocity is recently being possible. This is very important because the injection

process, especially the dispersion of jet fuel, is crucial for the combustion

process in the cylinder and consequently for the composition of exhaust gases.

And finally, the chemical composition of the fuel has a strong impact on the formation

of dangerous emissions, too. The research presents the influence of

various volume mesh types on flow characteristics inside a fuel injector

nozzle. Our work is based upon the creating of two meshes in the CFD software

package. Each of them was used two times. First, a time-dependent mass flow

rate was defined at the inlet region and pressure was defined at the outlet.

The same mesh was later used to perform a simulation with a defined needle lift

curve (and hereby the mesh movement) and inlet and outlet pressure. In next few

steps we investigated which approach offered better results and would thus be

most suitable for engineering usage.

Keywords: diesel engine, mass flow, CFD, needle

lift, injector, volume mesh

1. INTRODUCTION

The development of modern diesel

engines is directed to increase capacity and lower consumption. In future, it

will be especially oriented towards even greater fuel economy and purity of

diesel engines. Therefore, more and more manufacturers tend to develop engines

with smaller volumes, less cylinders and different systems for exhaust gas

treatment.

In achieving these goals, fuel

injection systems play an important role, since they are responsible for

just-in-time and regular supply of fuel to the engine cylinders. In the course

of time, there were several changes in their operation but the basic

characteristics remain the same until today. Increased awareness for the

environmental protection compel manufacturers to develop ever better and more

efficient fuel injection systems. The latest are electronically controlled and

allow precise control by opening and closing of valves, fuel injection time is

shorter while injection pressure is significantly higher. Electronically

controlled injection systems help to reduce harmful emissions (NOX,

soot) in the exhaust gases and to increase the engine power as well as reduce

the level of noise.

Such systems allow the injection

under high pressure (about 1500 to 2000 bars) which reduces the emissions of

solid particles. The higher the pressure, the better the dispersion (smaller

droplets) of the fuel is, which leads to better prepared mixtures at the same

time. By controlling the injection pressure that depend on the load and engine

frequency, these systems allow control of gaseous emissions and noise. For

simultaneous reduction of NOX and soot emissions, the optimal angle

of starting injection time is important. The latter is important due to the

interaction of different measures to reduce emissions of soot and NOX.

In turn, by reducing certain emissions, these measures often cause the increase

of others. The injection with common rail allows all the above requirements [1].

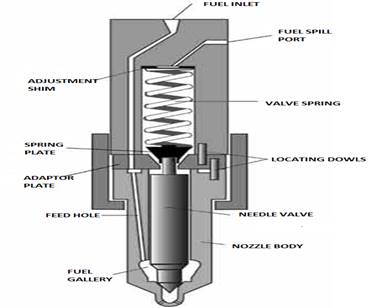

Fig. 1. Injector

The space, in which combustion takes

place, and the system of fuel supply are connected by the injector nozzle,

which is one of the most important elements of the fuel injection system. It is

used at the end of the compression phase to enable the supply of fuel under

high pressure to the combustion chamber. Injector nozzles take care of properly

atomized fuel, which is essential for good combustion, low fuel consumption and

the lowest emissions possible. Individual values of by-products of combustion

also depend on pressure of fuel injection, openness of nozzles and valves, fuel

characteristics and steering components [1].

Due to increased efficiency of the

process, several different versions of nozzles have been developed. Their

common task is to inject fuel into the cylinder of engine at optimum dispersion

[2].

2. DESCRIPTION OF EXPERIMENT

2.1. Computer fluid

dynamics (CFD)

Computers

have become an indispensable part of modern engineering practice. By using

computers, we can develop, design and improve old products faster. In the

sixties, the development of computer fluid dynamics has started. Its main

advantages, compared to conventional laboratory experiments, are the speed of

implementation, easy adaptability and lower price. Consequently, many

prototypes have not been required due to simulation which can figure out

whether something is going to work or not and can be improved by the use of

computer. For the purposes of CFD, there

are several different software packages. In our case, the program, which is

widely used in the automotive industry, was used for numerical simulation of

our problem. The program is based on the finite volume method to analyze fluid

flow [2].

2.2. Mathematical model of multiphase fluid flow in the selected CFD package

The object

of our research is the numerical analysis of simultaneous flow of two fluid phases

(vapor and liquid) through the injector of the fuel injection system. In order

to solve such a mathematical-physical model, it is necessary to solve a system

of conservation equations for each liquid phase separately.

The multiphase model describes each of the phases separately. The

conservation equations for each phase are connected with terms that describe

the transfer of mass, momentum, energy, turbulent kinetic energy and

dissipation of turbulent kinetic energy. These terms are the weakest point of

the multiphase model. In the Eulerian multiphase flow model, different

equations are separately numerically solved for each of the two phases (k and l) in the model [3].

Mass conservation:

![]() (1)

(1)

Here: rk – density of phase

k, ak – volume fraction

of phase k, vk – velocity of phase k, Gkl –

represents the interfacial mass exchange between phases k and l.

Here the

following condition must be fulfilled:

![]() (2)

(2)

Momentum conservation:

![]() (3)

(3)

Here: ![]() – body force vector which comprises gravity

– body force vector which comprises gravity ![]() and the inertial force in rotational frame,

and the inertial force in rotational frame, ![]() – pressure (values of pressure are supposed to

be equal for all phases),

– pressure (values of pressure are supposed to

be equal for all phases), ![]() – term which presents the momentum interfacial

interaction between phases k in l.

– term which presents the momentum interfacial

interaction between phases k in l.

The shear

stress ![]() of the k

phase is:

of the k

phase is:

![]() (4)

(4)

Reynolds

stress ![]() is:

is:

![]() (5)

(5)

Here: ![]() –

molecular viscosity,

–

molecular viscosity, ![]() – turbulent

viscosity

– turbulent

viscosity

Turbulent viscosity is modelled by:

![]() (6)

(6)

Energy (total enthalpy) conservation:

(7)

(7)

Here: ![]() – heat (entalpy) source,

– heat (entalpy) source, ![]() – represents the exchange of enthalpy between

phases k and l;

– represents the exchange of enthalpy between

phases k and l; ![]() – enthalpy of phase k; qk – heat flux.

– enthalpy of phase k; qk – heat flux.

Heath

flux qk is defined

by:

![]() (8)

(8)

Here: ![]() –

thermal conductivity of phase k

–

thermal conductivity of phase k

Turbulent

heat flux![]() :

:

![]() (9)

(9)

Turbulent kinetic energy

conservation:

(10)

(10)

The production term due to shear,

Pk, for phase k is:

![]() (11)

(11)

Turbulent dissipation equation: [4, 5]

(12)

(12)

Specifying mass transfer (mass

interfacial exchange):

the linear cavitation model was used. It based on the following relation

for the mass exchange:

![]() (13)

(13)

Where: ![]() – mass

transfer, N''' – bubble number density, R – radius of bubbles.

– mass

transfer, N''' – bubble number density, R – radius of bubbles.

2.3. Data for

numerical calculation

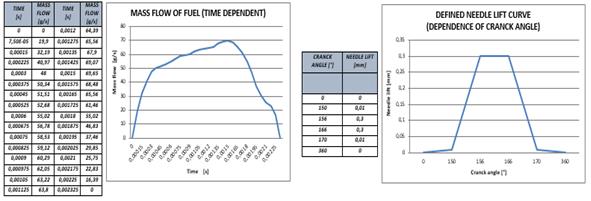

Entry data for the calculation were obtained by measurements which were carried out in laboratory of engines on Friedmann & Maier device for testing outside vehicle injection systems. By using this device, data about the fuel mass flow and needle lift were collected and were used as boundary conditions in the simulation. They are presented in Figure 2.

Fig. 2. Data about the fuel mass

flow (left) and needle movement (right)

The measurement was performed on the Bosch nozzle, type DLL 25 S 834, which is used in the engine of MAN D2566 MUM. The pressure of needle lift is 175 bars, the maximum lift of the needle is 0.3 mm. It has a bore diameter dn = 0.68 mm.

Fig. 3. Examined

injector (left) and Friedmann & Maier device for injection testing

systems (right)

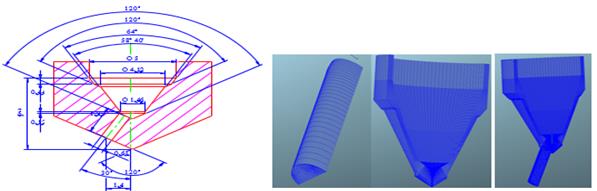

2.4. Model mesh

The simulation was carried out on the geometric

model of the extreme lower part of the injector, which covers the tip of the

needle, seat area and bore for fuel injection (flow out channel). The

geometrical model was formed from the 2D structure in Figure 4 (left). For the

purpose of numerical simulations, there were created two spatial meshes on the

model, consisting of 250.000 (mesh 1) and 400.000 (mesh 2) elements. At each

mesh there were conducted two simulations: the one with defined mass flow and

the one with defined needle lift (Figure 4, right).

Fig. 4. Injector construction (left) and

model mesh (injector body, fuel injection bore,

combined in one body)

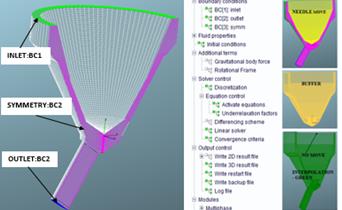

2.5. Boundary conditions of the model

The basic surfaces

(selections) of the model are: inlet, outlet and symmetry. For each of them

boundary conditions for multiphase flow were set. Furthermore, the parameters

for controlling the calculation, defining characteristics of the fuel, and

convergence criteria and parameters for postprocessing were determined.

In case of calculating the

defined needle movement, the type of simulation

"crank-angle" was used, which allows the change of conditions

depending on crank angle. Therefore, for the performance of these simulations,

besides the three already defined (Figure 5, left), 4 new selections were

created: Needle_move, Buffer, Interpolation and No_move (Figure 5, right).

Fig. 5. Selections of boundary conditions

(left), operational tree, additional selections of boundary conditions in case

of defined needle movement (right)

3. ANALYZING RESEARCH RESULTS

The review of results

included the analysis of velocity, turbulent kinetic energy and volume fraction

in the outlet. Simulated values of the flow characteristics for both of the meshes

and for both approaches at the flow inlet and outlet are introduced below.

Examples illustrate the results after 0.001125 s of simulation (about half of

the process).

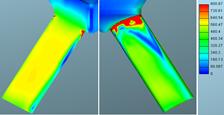

3.1. Velocity

The comparability of meshes

for both phases is relatively good in profile shape terms, but is very

different in absolute terms. As shown in the graphs, the calculated values for

the two phases are very similar at both the inlet and the outlet. However, the

difference between both approaches is substantial. The results match better at

the inlet to the bore. The values obtained with the defined needle movement

seem more realistic.

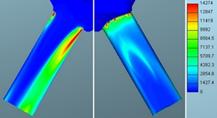

Fig. 6. Defined mass flow:

velocities of gaseous phase for mesh 1 (left) and mesh

2 (right) in m/s

Fig. 7. Defined mass flow: velocities of

liquid phase for mesh 1 (left) and mesh

2 (right) in m/s

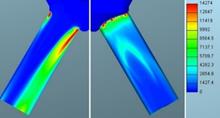

Fig. 8. Defined

needle lift: velocities of gaseous phase for mesh 1 (left) and mesh

2 (right) in m/s

Fig. 9. Defined needle lift: velocities of liquid phase for mesh 1 (left) and

mesh

2 (right) in m/s

Fig. 10. Comparison of velocity profiles:

Gaseous phase (left) – defined mass flow for meshes 1 and 2 and the defined

needle lift for meshes 1 and 2; Liquid phase (right) – defined mass flow for

meshes 1 and 2 and the defined needle lift for meshes 1 and 2

3.2. Turbulence

kinetic energy

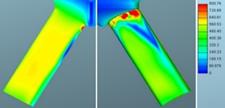

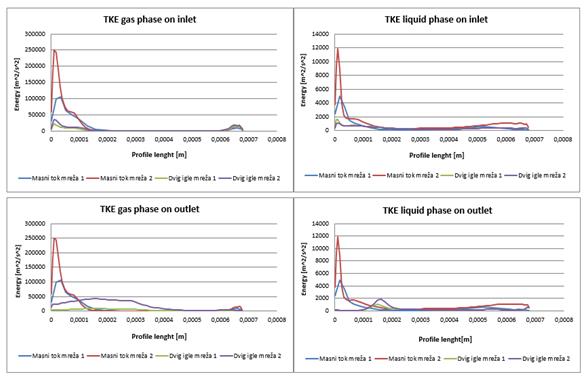

The comparison of results

between the two meshes shows that the results of TKE are relatively well

matched, and that there are only noticeable differences along the walls, while

after that the flows subside. Slightly larger deviation is observed in the

gaseous phase at the exit of the hole which is confirmed by the graphs of

numerical values. The mesh density seems to have made a large impact on both

approaches.

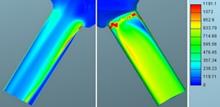

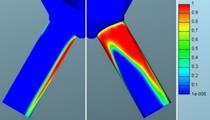

Fig. 11. Defined mass flow: Turbulence

kinetic energy of gaseous phase for mesh 1 (left)

and mesh 2 (right) in m2/s2

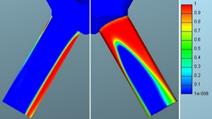

Fig. 12. Defined mass flow: Turbulence

kinetic energy of liquid phase for mesh 1 (left)

and mesh 2 (right) in m2/s2

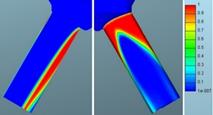

Fig. 13. Defined needle lift: Turbulence

kinetic energy of gaseous phase for mesh 1 (left)

and mesh 2 (right) in m2/s2

Fig. 14. Defined needle lift: Turbulence

kinetic energy of liquid phase for mesh 1 (left)

and mesh 2 (right) in m2/s2

Fig. 15. The

comparison of Turbulence kinetic energy (defined mass flow and needle lift -

meshes 1 and 2)

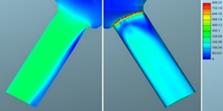

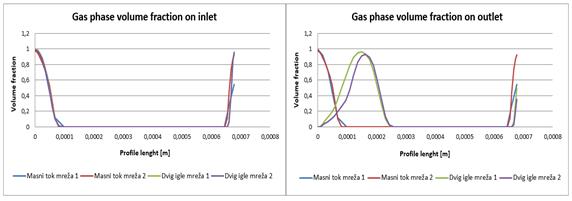

3.3. Volume fraction

The volume fractions match well

at the inlet, but some differences can be observed at the outlet of the bore.

This means that the gaseous phase moved closer to the center of the bore.

100% of gaseous phase![]()

![]()

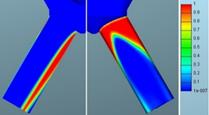

Fig. 16. Defined mass flow: Volume fraction of

gaseous phase for mesh 1 (left)

and mesh 2 (right)

100% of gaseous phase![]()

![]()

Fig. 17. Defined needle lift: Volume fraction of

gaseous phase for for mesh 1 (left)

and mesh 2 (right)

Fig. 18. The comparison of volume fraction

(defined mass flow and needle lift)

for meshes 1 and 2

4. CONCLUSIONS

In

the field of computational fluid dynamics, there is still quite a lot of

potential for improvement and innovation. Therefore, our research presents two

different modes of injector nozzle simulation and we try to determine whether

they are comparable or not. The first approach dealt with the defined

time-dependent mass flow at the entrance to the injector, and the data were

obtained experimentally. In the second case, the modelled calculations were

replicated with the defined needle lift and the pressure at the inlet. Both

were used at two different mesh volumes of numerical model.

It turned

out that the approaches gave different results. The particularly large

deviations occured in the calculated values of pressure and velocity. Much more

comparable results were gained by turbulent kinetic energy and volume

fractions.

It was also

noted that the discrepancy was greater at the exit of the bore. In both

approaches, partial reasons for the deviations resulted from in the inability

of choice of exactly the same time interval, although measurement error was

also possible. However, those factors could not be the cause of such large

deviations in the case of pressure, especially because in the post-analysis,

the possibility of incorrect settings in the control file was excluded.

Nevertheless,

we managed to approximate the results in two ways. First, the inlet pressures

were taken out of the results of simulation which was using the approach with

the defined mass flow. This information was then set as a boundary condition in

simulation, in which we defined the needle lift and pressure at the inlet. The

match was much better. Therefore, we believed that with some adjustments of

incoming data, especially with more accurately defined mass flow, we could

achieve a very good match. Then we did the reverse, and from the simulation

with the defined needle lift, the mass flows were received and were determined

at the inlet. There was again a very good match in results.

Despite

that, in the initial research phase, we could not confirm whether the approach

was entirely comparable or not. We estimated that it would make sense to re-do

the measurement of mass flow and needle lift, and after that simulations should

be replicated with much more accurate mathematical analysis of physical

conditions of the process, which would be subject to further consideration of

the problem.

References

1.

Kegl B. 2006. Osnove motorjev z notranjim zgorevanjem.

[In Slovenien: Fundamentals

of internal combustion engines]. Maribor: Fakulteta za strojništvo.

2. Volmajer M. 2001.

„Numerična in eksperimentalna analiza tokovnih karakteristik vbrizgalne šobe

dizelskega motorja”. [In Slovenien: “Numerical and experimental analysis of

flow characte9ristics of the injectors for diesel engines”]. MSc thesis. Maribor: TF.

3. Volmajer M. 2007. “Modeliranja večfaznih tokov v

vbrizgalni šobi”. [In Slovenian: “Modeling of multiphase flows in the injector”].

PhD thesis. Maribor: TF.

4. Manual Fire. AVL List GmbH. 2011. Graz.

5. Turbulence

modeling for beginners. Tennessee: Tony

Saad, University of Tennessee Space Institute. 2014. Available at:

http://www.cfdonline.com/W/images/3/31/Turbulence_Modeling_For_Beginners.pdf.

Received 11.08.2015;

accepted in revised form 21.12.2015

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License