Article citation info:

Vojtková, J. Reduction of contact stresses using involute gears with asymmetric teeth. Scientific Journal of Silesian University of Technology. Series Transport. 2015, 89, 179-185. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2015.89.19.

Jarmila VOJTKOVÁ[1]

REDUCTION OF CONTACT STRESSES USING INVOLUTE GEARS WITH ASYMMETRIC TEETH

Summary. Asymmetrical involute gears have a different

value of the operating pressure angle for right and left side of the gear.

These teeth are suitable for one direction of rotation. Such teeth enable to

change the length of the generating line. They enable to improve the value of

reduced radii of curvature. Asymmetrical teeth allow reducing the values of

Hertz's pressures, especially on the root of the teeth. Hertz pressures

are directly related to the asymmetry.

Keywords: contact stresses, gear, involute,

asymmetric teeth

1. Introduction

In practice, cogwheels with

involute gears are used the most. Their production is common and their accuracy is

aceptable. [1-7]. However, to lower the value of contact stresses, gears with

asymmetric teeth might be more suitable. Their price should not be a main

criterion when working with them. With a well-designed gear with asymmetrical

teeth, a considerable decrease in the values of contact stresses can be

noticed, and in some cases also a decrease in vibrations. From this point of

view, the spur gears with non-symmetrical teeth are becoming a great

alternative. [1-2].

2.

Suitable TOOTH Design

Area For GEAR with asymmetric teeth

The driving side has a

differnet pressure angle than the opposite side, and

therefore an asymetrical tooth is being created. An angle larger than

20° is more advantageous for the driving

side. The angle of the opposite side has a considerable influence only during

the reverse movement. Base circle diameter significantly

decreases with increasing

pressure angle. The larger the difference

between the angles of a profile, the more pronounced is the asymmetry, and hence there is a significant

difference between the diameters of

the base circle. [1].

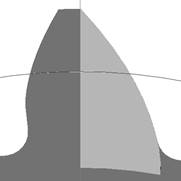

An asymmetrical tooth, an axis of

tooth, and a pitch circle are drawn on Fig. 1. The circular pitch measured

on the pitch circle is identical for the left and right side. The tooth

thickness, measured mostly on a top land, is changing relative to the angle of

stress, which influences the ability to create a correct tooth.

Fig. 1. Asymmetrical tooth, ha*= 1, left side

pressure angle αL=20º, right side pressure angle αP=35º

The minimum number of teeth with

allowable undercutting z´min

![]()

(1)

Where:

ha* − sufficient tooth

addendum,

α − pressure angle [°].

Values of a minimal amount of teeth z´min relative to the angle

of profile α, for various values

of top land tooth height ha*,

are depicted on Fig. 2. The curves take into consideration the allowable

undercutting. For larger values of the profile α angle, the values of minimal amount of teeth are decreasing

pronouncely.

The area of the accurate tooth

design is dependent on the following parameters:

- number of teeth,

- sufficient

tooth addendum ha*,

- pressure

angle for the opposite side of tooth,

- the

stresses on the non-funtional side of the tooth,

- the

required value of top land tooth thickness.

Z´min α (°)

Fig. 2. The minimum number of

teeth with allowable undercut depending

on the pressure angle

Half the top land thickness

![]()

(2)

Where:

da − tip circle diameter [mm],

d − pitch circle

diameter [mm],

m – module [mm],

αa − pressure angle at the tip circle [°].

These parameters imply a possible

design area of an accurate tooth creation, which satisfies the geometrical

parameters. An area for accurate tooth creation for parameters z1=17,

ha*=1 is

shown in Fig. 3. For a certain number of teeth, based on an angle αL, the values of the angle on the right side can be determined in the

graph (Fig. 3). For example, z1=17, ha*=1, αL=20° can

have an angle αP in the interval < 20°,

38.5°>. This area decreases in size with a smaller

number of teeth.

Fig. 3.

Suitable tooth design area for z1=17, ha*=1

Table 1

The top land thickness and contact

ratio for m=10mm, gear ratio u=1

|

ha* |

z1 |

αL (°) |

αP (°) |

saL/2 (mm) |

saP/2 (mm) |

εαL |

εαP |

z2hL |

|

0,9 |

8 |

25 |

38 |

2,692 |

-0,185 |

1,128 |

1,041 |

11 |

|

10 |

23 |

40 |

3,190 |

-0,550 |

1,202 |

1,059 |

22 |

|

|

14 |

19 |

43,5 |

4,013 |

-1,362 |

1,370 |

1,083 |

27 |

|

|

17 |

17 |

45,5 |

4,401 |

-1,898 |

1,488 |

1,097 |

30 |

|

|

1 |

10 |

24 |

32,5 |

2,232 |

0,372 |

1,294 |

1,194 |

18 |

|

14 |

20 |

37,5 |

3,230 |

-0,669 |

1,463 |

1,201 |

26 |

|

|

17 |

18 |

39,5 |

3,697 |

-1,116 |

1,582 |

1,209 |

31 |

|

|

1,1 |

14 |

21 |

30 |

2,375 |

0,270 |

1,553 |

1,370 |

25 |

|

17 |

19 |

33,5 |

2,929 |

-0,351 |

1,672 |

1,361 |

32 |

The limits values of the angles α for the right and left side, with a full degree precision for the left

side and 0,5° precision for the right

side, for a various amount of teeth are mentioned in Tab. 1. The values of half top land tooth thickness are also

mentioned there. The value z2hL is the limit value of the number of teeth, for

the gear ratio u=1. If the number of teeth is greater than z2hL, point A is outside the interval N1N2

(interference). For a larger gear ratio, the value of the limit of the

teeth z2h increases.

3. The radii of curvature and Hertz pressures

A view of various

sides of the tooth, where the length of the contact line and radii are

changing, is on Fig. 4.The change of pressure angle α leads to changes in the radii of

curvature (Fig. 4), which affect the Hertz pressures.

Tab. 2 shows the values of the radii of curvature, mesh points

A, C. [1].

a)

b)

Fig. 4.

Mesh assymetrical toth: a) driving side αL=20°, b) driving side

αP=35°

The

value of Hertz pressure is changing in relation to the contact point. It has

the least advantageous values in the place of the first mesh point, at the

dedendum of the pinion. The regular values of the pressure in the gearing

can be approximately determined in a following matter: For symmetrical

gearing, if the pressure value of 100%

is at the pitch point, then this value at the dedendum is approximately 150% and approximately 95% at the top of the pinion in

relation to the gearing geometry. [8]. The

values of the pressures can be determined based on the circumference force. The

second option is to determine these values on the basis of normal force, which

value changes depending only on the amount of tooth pairs in the mesh, and is

constant for a single contact. Double tooth contact is also being considered in

the calculation.

Table 2

Reduced radii

of curvature and values corresponding to Hertz pressure for Ft=1N

|

z1 |

z2 |

α (°) |

Point C |

Point A |

||||

|

ρ1C

(mm) |

√(Ft/(ρR.cosαt)) (N/mm)-1/2 |

% |

ρ1A (mm) |

√(Ft/(ρR.cosαt)) (N/mm)-1/2 |

% |

|||

|

10 |

10 |

24 |

20,337 |

0,3281 |

100 |

1,769 |

0,5688 |

173 |

|

32,5 |

26,865 |

0,2971 |

91 |

11,048 |

0,2497 |

79 |

||

|

18 |

24 |

20,337 |

0,2894 |

100 |

0,022 |

4,9947 |

1726 |

|

|

32,5 |

26,865 |

0,2620 |

91 |

10,119 |

0,2602 |

90 |

||

|

14 |

14 |

20 |

23,941 |

0,2982 |

100 |

2,351 |

0,4879 |

164 |

|

37,5 |

42,613 |

0,2432 |

82 |

27,643 |

0,1837 |

62 |

||

|

26 |

20 |

23,941 |

0,2615 |

100 |

0,016 |

5,7701 |

2207 |

|

|

37,5 |

42,613 |

0,2133 |

82 |

27,079 |

0,1730 |

66 |

||

|

17 |

17 |

18 |

26,266 |

0,2830 |

100 |

2,634 |

0,4584 |

162 |

|

39,5 |

54,067 |

0,2190 |

77 |

39,408 |

0,1608 |

57 |

||

|

31 |

18 |

26,266 |

0,2490 |

100 |

0,041 |

3,5680 |

1433 |

|

|

39,5 |

54,067 |

0,1927 |

77 |

38,991 |

0,1494 |

60 |

||

Reduced radius of curvature

ρR for the

mesh points:

|

|

(3) |

Where:

ρ1 – radius of curvature with respect to the

pinion [mm],

ρ2 – radius of curvature with respect to the

wheel [mm].

Hertz

pressures are directly related to the asymmetry. The

values of the reduced radii of curvature at the pitch point C and point A are calculated in Fig. 2. The value √(Ft/(ρR.cosα)) is

in proportion to the course of stresses. This value for pitch point C is defined as 100%. The change

corresponding to the change in stresses at a specific point can be seen in Fig.

2. For example, for values z1=

z2=17, ha*=1, an angle αL=18° is the stress at the

pitch point C with the value 100%, in point A with 162%, and decreases for angle αP=39,5° to 77% in point C, and to 57% in point A. If the angle of the driving side is 39,5°, the values of stresses are considerably more advantageous.

ρ1 [mm]

Fig. 5. The course of

mathematical term determining the course of a Hertz pressure, force

Ft = 1N, z1=17, z2=17, ha*=1, ![]() αL=18°,

αL=18°, ![]() αP=39,5° with a double tooth contact

αP=39,5° with a double tooth contact

Hertz pressure by normal force

|

|

(4) |

Hertz pressure by tangential force

|

|

(5) |

Where:

zM

− material factor [MPa1/2],

Ft

− tangential force [N],

Fn

− normal force [N],

bw

− axial face width [mm],

αt

− pressure angle in a transverse plane [°],

E − modulus of elasticity [MPa].

4.

Conclusion

The use of gears with asymmetric teeth can

be a good alternative to reduce

Hertz pressures. Well-designed gearing can be achieved to reduce the size, significantly reduce

contact stresses especially

in the dedendum of the pinion.

This paper

was written in the framework of Grant Project VEGA: “1/0688/12– Research and application of universal regulation system in order to master the source of mechanical systems

excitation.”

References

1.

Vojtková J. 2014. „Effect of asymmetry on radii of

curvature for spur gears with nonsymmetrical teeth“. Scientific Journal of Silesian University of

Technology. Series Transport 84: 47-51. ISSN 0209-3324.

2. Di Francesco G., S. Marini. 2007. Asymetric Teeth: Bending Stress Calculation.

In:

http:// www.geartechnology.com. March/April 2007.

3. Wojnar

G., P. Czech, P. Folega. 2014.

“Problem with Diagnosing local faults of gearboxes on the basic of vibration

signal”. Transaction of the Universities

of Košice 2: 95-100. ISSN: 1335-2334.

4. Czech

P., P. Folega P., G. Wojnar. 2014.

„Taking Advantage of empirical mode decomposition in diagnostig IC engine

faults”. Transaction of the Universities

of Košice 2: 17-22. ISSN: 1335-2334.

5. Czech P., J. Mikulski. 2014. “Application

of Bayes classifier and entropy of vibration signals to diagnose damage of head

gasket in internal combustion engine of a car”. Communications in Computer and Information Science 471: 225-232. ISSN:

1865-0929.

6.

Homišin J., P. Kaššay, P. Čopan. 2014. „Possibility of torsional vibration extremal control”. Diagnostyka 15(2): 7-12.

7.

Haľko J., S. Pavlenko. 2012. „Analytical suggestion of

stress analysis on fatigue in contact of the cycloidal - vascular gearing

system“. Scientific Journal of

Silesian University of Technology. Series Transport 76: 63-66. ISSN

0209-3324.

8. Moravec V. 2001. Konstrukce strojů a zařízení II. Montanex.

[In Slovak: Construction machinery and equipment II].

Received 09.05.2015; accepted in revised form 24.09.2015

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons Attribution

4.0 International License