Article citation info:

Urbanský, M., Kaššay, P. The new realized mobile device for extremal

control research and presentation. Scientific

Journal of

Matej URBANSKÝ[1],

Peter KAŠŠAY[2]

The

new realized

Summary. At our

department we deal with torsional oscillating mechanical systems (TOMS)

continuous tuning during its operation in terms of torsional oscillation size. Therefore

was build the new mobile device for research and presentation purposes of the

TOMS continuous tuning using extremal control method. This paper deals mainly with

design of the mobile device and its special compressed air distribution system,

which is necessary for its regular function.

Keywords: torsional

oscillating mechanical system, continuous tuning, extremal control

1. INTRODUCTION

In

the laboratory of our workplace – Section of machine design and machine parts

of Department of Construction, Automotive and Transport Engineering we attend

to measuring and tuning of torsional oscillation in torsional oscillating

mechanical systems (TOMS), mainly during their operation, i.e. publications [1-6, 8].

One of the methods of continuous tuning is the application of the extremal control

– experimental optimization, which is detailed described i.e. in publications

[2-4]. For research and presentation purposes of TOMS continuous tuning using

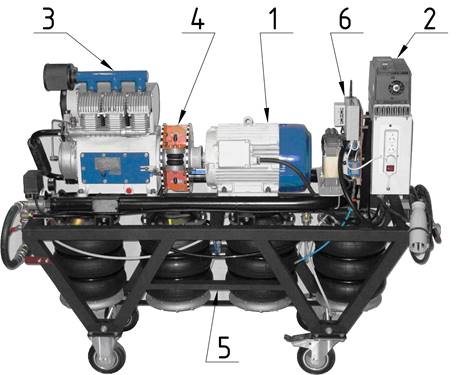

extremal control method was build the new mobile mechanical device (Fig. 1).

For regular function of this device was moreover necessary to build the special

compressed air distribution system. This paper therefore deals with design of

this mobile device and its special compressed air distribution system and with determination

of volume of air springs, which are modified and used as air pressure tanks.

2. DESCRIPTION OF THE NEW BUILD

In Fig. 1 we can see that the basic

part of this new build mobile device is the torsional oscillating mechanical

system (TOMS). This TOMS consists of 3-phase asynchronous electromotor MEZ

4AP132M-4 (nominal power 7,5 kW at 1450 min-1) (1), whose

rotation speed is continuously vector-controlled by the frequency converter

Sinamics G120C (2). Electromotor drives the 3-cylinder piston compressor ORLIK

3JSK-75 (3) through the pneumatic tuner of type 4-2/70-T-C (4). This TOMS

is situated on rigid frame, which is flexibly mounted on the mobile platform

(5). Next component situated on the mobile platform (5) is electronic extremal

control system called ESLER (6) and its accessories (sensors, actuators, etc.).

Current level of ESLER function is in detail described in [4] and the whole

process of torsional oscillation data measuring and evaluation using optical

sensors is described in detail in [8].

Fig. 1. The new build mobile device

for extremal control presentation

As base for the mobile device

construction was therefore used the standard ORLIK compressor system

(Fig. 2), with originally air pressure tank (

Fig. 2. The standard compressor

system ORLIK

3. MOBILE PLATFORM WITH compressed air distribution system

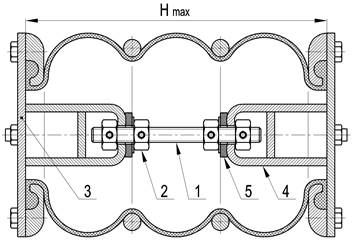

The main parts of the mobile platform

(position (5) in Fig. 1) are the steel frame, four air springs RUBENA

340/3, modified (Fig. 3) and used as air pressure tanks and the special

compressed air distribution system (Fig. 4).

Fig. 3. The modified air spring

The mobile platform must insure the

following functions:

■ carrying and transport of whole system,

■ compressed air storage for pneumatic coupling inflation,

■ compressor delivery pipe volume compensator

for properly adjustment of compressor delivery pressure and thereby TOMS load

too.

Modified air springs RUBENA 340/3

were used as air pressure tanks (Fig. 3). The threaded rod (1),

situated in air spring axis (axis of rotational symmetry) with four lock-nuts

(2) screwed on it are keeping from unwanted air spring extension at its

inflation and unwanted air spring retraction at its deflation, mainly when in

the air spring is zero overpressure value. Axial forces from air spring sealing

flanges (3) to the threaded rod are transmitted through cross-stiffened forks

(4), welded to inner sides of air spring sealing flanges. The hard rubber

plates (5) between lock-nuts allow small parallelism deviations of air spring

sealing flanges. The air spring stroke is therefore constant and it is adjusted

to value Hmax = 340 mm, which is maximal air spring

stroke operation value according to manufacturer catalog [8]. Maximal air

overpressure in the tanks is 700 kPa.

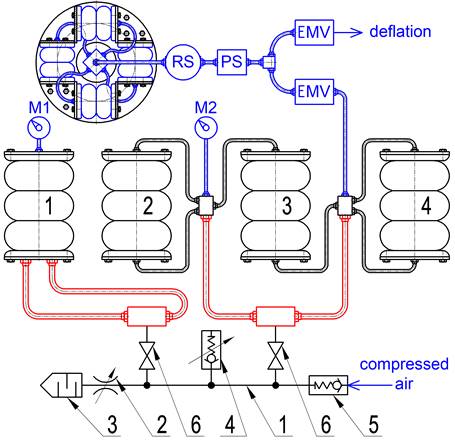

Fig. 4. The special

compressed air distribution system

The special compressed air

distribution system (Fig. 4) allows through inter-connections the use of

modified air springs as:

■ compressed air storage for pneumatic coupling inflation (air

springs 2,3,4),

■ compressor delivery pipe volume compensator (air spring 1).

In Fig. 4 we can see that the

compressed air from compressor streams into the compressor delivery pipe (1)

(1" piping), which finished with throttle valve (2) and noise

silencer (3). With this throttle valve we can adjust compressor delivery

overpressure and thereby the TOMS load too, since the transmitted load

torque in TOMS at certain constant rotational speed increases with increasing

compressor output air overpressure [9]. For accurate and comfortable adjustment

of compressor delivery pressure is to delivery pipe connected the volume

compensator (air spring 1). Whole compressor delivery pipe is protected against

inadmissible overpressure increase by mechanical safety pressure valve (4)

(after backflow valve (5)) and by electrical safety pressure valve – total

stopper (before backflow valve, do not shown in Fig. 4). Interconnected

air springs 2,3,4 serve as compressed air storage for pneumatic coupling

inflation. Compressed air streams through electromagnetic valve (EMV), pressure

sensor (PS) and rotational air supply (RS) into pneumatic coupling. Air spring

1 and interconnected air springs 2,3,4 can be using ball lock valves (6)

alternately connected on or disconnected off the compressor delivery pipe, as

necessary. It is necessary to say that all actuating components (2), (6) and

indicators (manometers M1 and M2) must be situated so close together as

possible and they must allowing good manipulation and view. At the same time

that components must be situated beyond reach of rotary or electrical parts of

mechanical system. In our case they are situated on the left frame forehead

(Fig. 1).

4. APPROXIMATE determination of air springs volume

For computation of certain next

parameters of the system was necessary to determine the approximate volume

of modified air springs, described in previous chapter. This determination was

realized on the principle of air pressure equalization between known volume VN

(

(1)

(1)

Where ppN is air

overpressure in the

Because of isothermal process was

considered, it was important to wait enough long time for ppC and ppN

values consolidation. For accurate measurement of the pressure was used the pressure

sensor of type Danfoss MBS 3000 (0÷10 bar range of measure).

Table 1

Measured and computed values for air springs volume determination

|

ppN [kPa] |

800 |

750 |

700 |

650 |

600 |

550 |

500 |

450 |

400 |

|

ppC [kPa] |

628,6 |

590,3 |

552 |

513,5 |

474,6 |

435,8 |

397,1 |

358,4 |

319,5 |

|

volume VS [l] |

81,7 |

81,2 |

80,4 |

79,7 |

79,3 |

78,6 |

77,7 |

76,7 |

75,6 |

|

1 air spring volume [l] |

20,17 |

20,04 |

19,86 |

19,69 |

19,57 |

19,40 |

19,18 |

18,92 |

18,65 |

From Tab. 1

we can see that the average 1 air spring volume is 19,5 l. Values of VS

increase with increasing ppN values. This fact is caused by extensibility

of air springs rubber-textile coat. Volume of 1 air spring is computed without

the piping-volume.

5. CONCLUSION

In term of safety of our new build

mobile device is even necessary to install protection covers in TOMS, namely:

■ rotary parts cover, mainly over pneumatic coupling,

■ pneumatic system cover around steel frame,

■ electrical parts cover over choke coil and frequency converter

terminal board.

References

1.

Grega

Robert. 2014. „Examination of

applicated pneumatic flexible coupling and its effect on magnitude of vibrations

in drive of belt conveyer”. Scientific

Journal of Silesian University of Technology. Series Trasnsport 85 (4):

21-25. ISSN 0209-3324.

2.

Homišin

Jaroslav. 2002. Nové typy pružných

hriadeľových spojok: Vývoj-Výskum-Aplikácia. Košice: Vienala. ISBN

80-7099-834-2. [In Slovak: New types of

couplings flexible shaft: Development-Research-Application].

3.

Homišin

Jaroslav, Peter Kaššay. 2014. „Experimental

verification of the possibility using pneumatic flexible shaft couplings for

the extremal control of torsional oscillating mechanical system”. Diagnostyka 15 (2): 7-12. ISSN

1641-6414.

4.

Homišin

Jaroslav, Matej Urbanský. 2015. „Partial

results of extremal control of mobile mechanical system”. Diagnostyka 16 (1): 35-39. ISSN 1641-6414.

5.

Patent

no.259225. Regulačný systém pre

zabezpečenie plynulej zmeny charakteristiky pneumatických spojok. Homišin

Jaroslav. 1987. [In Slovak: Regulatory

system to ensure smooth changes in the characteristics of pneumatic clutches].

6.

Patent PL 216901 B1. Układ mechaniczny strojony w sposób płynny. Homišin J. 2014. [In Polish: Mechanical tuned smoothly].

7.

Rubena. „Air Springs / Couplings / Compensators /

Washers”. Available at:

http://www.rubena.cz/air-springs/t-659/

8.

Urbanský

Matej, Jaroslav Homišin. 2014. „Use

of optical sensors for measuring of torsional oscillation size”. In:

Inżynier 21. wieku: 4. Międzynarodowa

Konferencja Studentów oraz Młodych Naukowców: 343-348. Akademia

Techniczno-Humanistyczna, Bielsko-Biała, Poland. 05 December 2014,

9.

Urbanský

Matej, Pavol

This paper was written in the

framework of Grant Project VEGA: „1/0688/12

– Research and application of universal

regulation system in order to master the source of mechanical systems

excitation”.

Received

23.10.2014; accepted in revised form 25.06.2015

![]()

Scientific Journal of