Article citation info:

Medvecká-Beňová, S. Deformation and stiffness of spur gear teeth and their influence on gear noise. Scientific Journal of Silesian University of Technology. Series Transport. 2015, 89,

101-107. ISSN: 0209-3324. DOI: 10.20858/sjsutst.2015.89.11.

Silvia MEDVECKÁ-BEŇOVÁ[1]

DEFORMATION AND STIFFNESS OF SPUR GEAR TEETH AND THEIR INFLUENCE ON GEAR NOISE

Summary. Gear teeth are deformed due to the load. The

deformation of gear teeth is causing some negative as well as positive effects.

A tooth has a complex shape and due to the complex shape of the teeth, a

theoretical determination of the deformation is difficult. The existing

experimental techniques are based on static deflection measurements gearing

loaded of constant force or seismic measurement deviations at slow rotation.

Recently, at ever faster evolving computer technology and the available

literature, we can encounter modern numerical methods, such as finite element

method (FEM), which can serve as methods for the determination of teeth of gearing. The article is devoted to the problems

of gearing stiffness analysis. The problem is solved for spur gears.

Deformation analysis solved by FEM is used for calculations of the gearing

stiffness. There are many influences that cause vibrations in the gearbox and

that have to be taken into account already in the phase of design, manufacture,

installation and operation. Detailed

analysis of gearboxes manufacturers have shown that improving of the gear

accuracy cannot reduce the transmission unit noise to the desired level. Only

fundamental changes to the shape of the tooth and changes in production

technology can achieve stronger noise reduction of gear mechanism.

Keywords: spur gear, gear noise, teeth deformation,

stiffness, FEM

1. Introduction

The

development of engine plants in past focused on the aquisition of the highest

capacity and durability. Engines and machines with gear transmission are very

popular and draw sufficient attention. Lowering the weight of the construction

machines and engine plants as well as increasing their efficiency and

productivity, are all part of the compelling task the construction, technology

and research workers must accomplish. These intensity factors have often a

significant influence on the increment of vibrations and noise in the monitored

engine plants. The society becomes gradually more intetested in these noise and

vibration emissions produced by the gearing mechanisms. The issue of lowering

noise emission in a gearbox is interconnected with the sources of noise,

together with measurement and evaluation of vibrodiagnostic performance.

Current products constructed with the usage of computer programs for the

firmness check of suggested solutions (FEM) together with the rich experience

of construction workers, reach optimal parameters from the perspective of

rigidity, material utilization and longetivity.

2. SOURCES OF

NOISE IN THE GEARBOX

The

gearbox is an audible enclosed system, from which the noise travels through

vibrations of the closet surface or plugged aggregates inclusive of the base

construction. One of the essential causes of noise is so-called transmission

error. This error is related to kinematic accuracy and durability of the

cogging.

The

vibrations from the spur gear, transmitted to the case of gearbox, are the most

important source of noise. From the physical point of view, the cause of

vibrations is the dynamic force which can change its amplitude, direction

or origin. The most critical change of amplitude in the evolvent cogging, which

main cause is stiffness of teeth and bursts when cogs enter the gear, due to

the deformation, deviation of gaps and cog profile from the theoretical ones.

Many other effects, i.e. vibrations transmitted into the cogging from the driving

or powered aggregate, oscillation of the arbors and bearings, influence the

vibrations in cogged wheels in a mesh. All of these elements play a role in the

enlargement of amplitude in cogging. The total energy of the radiated noise

further increases.

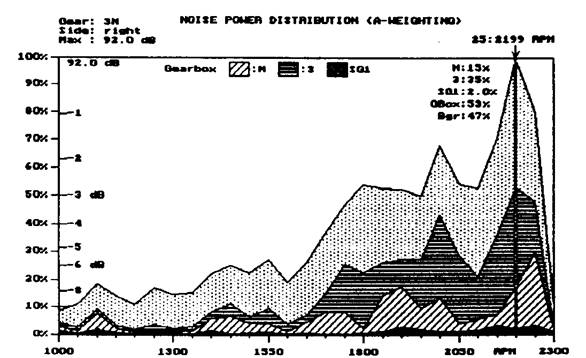

A dominant contribution of noise in

a gearbox; however, comes from the creation of vibrations during

intervention of the cogged wheels. On Figure 1, a total evaluation of

gearbox noise in an automobile, where the contribution of separated noise of

the gearbox intervention (defined as N and 3) is at maximum 40 % of the gearbox

noise with acontribution of 53% to the total noise, is displayed. The remaining

47% constitute for the background noise (defined as Bgr), inside which mainly

the noise created by bearing is incorporated [6].

The

noise in gear transmissions particularly affects periodic change of stiffness

teeth during meshing caused by changing the number of pairs of teeth, which are

simultaneously in meshing.

Fig. 1. Example

of evaluation of noise

gearbox of car [6]

3.

THE TEETH STIFFNESS AND THEIR IMPACT FOR

GEARBOX NOISE

Periodic

changes in the stiffness tooth mesh, caused by changes in the number of pairs

of teeth, which are also mesh in a significant noise impact on teeth. Stiffness

of gearing is defining as a proportion load across the width of the teeth and

the resulting deformation [1]. Since the involute tooth of spur gear has a

complex shape, the theoretical determination of the deformation the tooth

is a difficult. The

existing experimental techniques are based on static deflection measurements

gearing loaded of constant force or seismic measurement deviations at slow

rotation. Recently we can meet with modern numerical methods, such as finite

element method (FEM), which can serve as one of the methods for the determination

of deformation gearing [4]. As the basis for calculating the stiffness of

gearing results serve deformation analysis examined gearing solved by FEM.

Create

a geometric model of the gear is considered the first step to deal with tooth

deformation FEM. Universal user to create geometry computer model does not

exist. In this case, the geometric model has been created a combined method.

The final shape of 2D was by created in program AutoCAD. 3D model of examined

the spur gear with straight teeth was by created in program COSMOS/M as editing

from the 2D model. To determine the computer model for studying deformation of

the teeth using FEM was necessary to determine the material constants,

define the type of finite element, and selecting appropriate boundary

conditions (geometry and power).

We

will focus on the value of the total deformation in the direction of action

forces. To determine the deformation of gearing under load is necessary to

know the apportionment of the load on each gearing pairs with two pairs

meshing. At the beginning was considered with the simplest, ideal load

apportionment. The load for the two pairs meshing is divided by half for each

couple of teeth in the meshing.

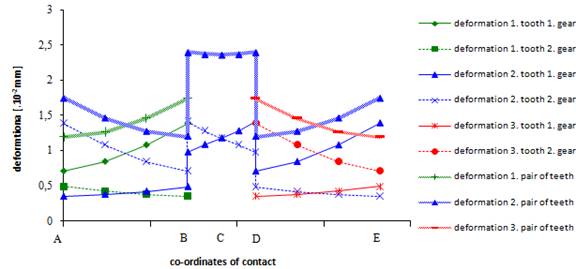

To

determine the resulting deformation of the teeth is necessary to determine the deformation

of individual pairs. In Figure 2 shows the progress of the overall deformation

of teeth solved by FEM for the spur gears with number of teeth z1,2=24, the module of teeth m=3,75[mm], the force FN=1000[N] and width of gearing

b1,2=10[mm], which in the

meshing reaching gear ratio 1 and for the ideal division of load. Deformation

of pairs of teeth over the meshing along the length of meshing line is changes.

Maximum value

of deformation shall in this case the endpoints lonely meshing (if we consider

the image-pair) and the minimum value shall also meshing in two pairs of

endpoints lonely meshing. The points B and D, it is the solitary meshing

points leads to a step change deformation teeth and it will input the next

couple teeth to meshing.

Fig.

2. Course

of tooth deformation

One

of the ways to specify the tooth stiffness is calculated using the total

deformation gearing determined by finite element method (FEM). In general the resulting stiffness c defined

by equation (1):

![]() , p = I, II

[N/mm.μm] (1)

, p = I, II

[N/mm.μm] (1)

where:

w

− load across the width of the teeth, equation (2) [N/mm] ;

δ

− the resulting deformation [μm].

![]() (2)

(2)

where:

wI − load across the

width of the first pair of teeth [N/mm] ;

wII − load across the width of the second pair of teeth [N/mm].

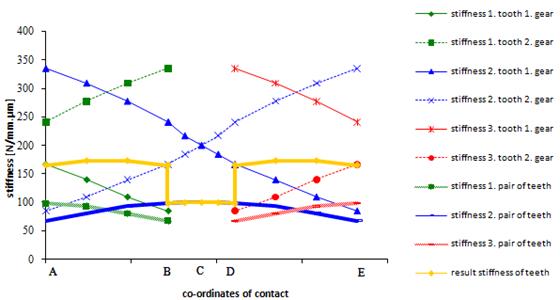

Fig.

3. Course

of tooth stiffness

In Figure 3 shows the course of total stiffness of the teeth, tooth pair

stiffness and total stiffness of gear teeth for the spur gears, in the teeth,

which in the meshing reaching gear ratio 1. The stiffness is individual pairs of teeth in the

mesh by changing the length of the engaging line. The minimum value shall end

in the engaging points

and lines shall

at maximum point

lone mesh, the so-called pitch point C. The resulting stiffness teeth after

track mesh changes periodically with

a period equal to the basic

pitch frontal. The endpoints solitary

mesh leads to sudden changes in stiffness resulting teeth. This

is due to a step change in deformation resulting

from the entry into another

pair of teeth in the mesh his cause’s vibrations that

cause noise gearbox.

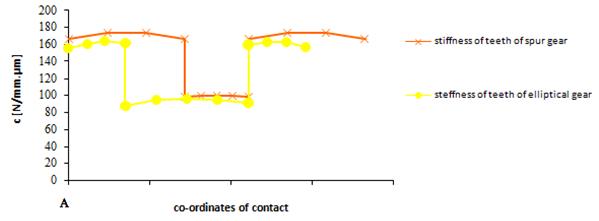

Fig.

4. Comparison

of stiffness

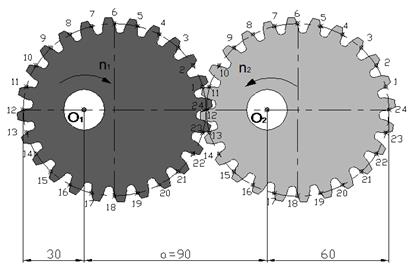

In figure 4 shoes the comparison of stiffness of spur gear and elliptical

gear. The elliptical gear is gear with variable transmission in the range

u = 0,5 to 2,0 ,with the number of teeth z1 = z2 = 24 and gearing module

mn= 3,75[mm] the distance a = 90[mm] and for a one direction of rotation. They are elliptical gears with axes of

rotation of gears placed eccentrically (Figure 5). The centers of rotation are

also focus points of the ellipse. Curved

active surface of tooth forms is involuta. Torque transmission ensures shape

bonded between meshing gears. The gearing consists of two identical gears. In Figure 4 shows the progress of the overall stiffness of teeth,

which in the meshing reaching gear ratio 1. Applies to, that if is the curve of the stiffness smooth, the noise in

gearing is lower. Then the noise

in elliptical gear is higher than the noise in the spur gear during meshing.

Fig.

5. Designed elliptical gear

4. CONCLUSION

There are many influences that cause vibrations in

the gearbox to be taken into

account already in

the design, manufacture, installation

and operation. Detailed analysis of gearboxes manufacturers have shown that improving the accuracy of gears cannot

reduce noise transmission

unit to the desired level. Only fundamental changes to the shape of the tooth and

changes in production technology can

achieve stronger noise

reduction gear mechanism.

This paper

was written in the framework of Grant Project VEGA: “1/0688/12– Research and

application of universal regulation system in order to master the

source of mechanical systems excitation.”

References

1.

Czech P., P. Folęga,

G. Wojnar. 2009. „Evaluation of influence of

cracking gear-tooth on hanges its stiffness“. Acta Technica Corviniensis – Bulletien of Engineering 4: 17- 22.

2.

Hyben B., M. Žmindák, A. Sapietová. 2013. “Dynamic

analysis of the properties of point machine EP600”.Technológ 04: 67-70. ISSN 1337-8996.

3.

Jakubovičová L. 2013. “Analysis of the roller bearing

mutual slewing effect on limit contact stress values”. Technológ 04: 79-82. ISSN 1337-8996.

4.

Medvecká-Beňová S. 2007. „Analysis of factors which are

influence of noisiness of change gearbox“. Acta

Mechanica Slovaca 11(4-A): 43-48. ISSN 1335-2393.

5. Medvecká-Beňová

S. 2011. „Deformácia a tuhosť čelného

ozubenia“. Strojárstvo 15(12):

8-9. ISSN 1335-2938. [In Slovak: “Deformation and stiffness spur”].

6.

Medvecká-Beňová S., Bigoš P. 2013. „Analysis of noise reduction of gear

transmissions“. In 13th

International Multidisciplinary

Scientific Geoconference: Ecology, Economics, Education and Legislation: 16-22. June,

2013, Albena, Bulgaria. ISBN 978-619-7105-04-9. ISSN 1314-2704.

7.

Satiepkova A., V. Dekys, M. Budinsky. 2012. “Utilizing

of sensitivity analysis in preparation of optimizing procedure”. Scientific Journal of Silesian University of

Technology. Series Transport 76: 113-118. ISSN 0209-3324.

Received 11.05.2015; accepted in revised form 21.09.2015

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons Attribution

4.0 International License