Article citation info:

Kaššay, P., Urbanský, M. Torsional natural frequency tuning by means of

pneumatic flexible shaft couplings. Scientific

Journal of Silesian University of Technology. Series Transport. 2015, 89, 57-60. ISSN: 0209-3324. DOI:

10.20858/sjsutst.2015.89.6.

Peter KAŠŠAY[1],

Matej URBANSKÝ[2]

TORSIONAL NATURAL FREQUENCY

TUNING BY MEANS OF PNEUMATIC FLEXIBLE SHAFT COUPLINGS

Summary. This

article deals with the use of pneumatic flexible shaft couplings as device for

tuning torsional natural frequencies of mechanical systems. These couplings are

using air bellows as flexible elements. Their torsional stiffness can be

changed by air pressure change, the natural frequencies of whole mechanical

system may be adjusted on desired value.

Keywords:

torsional vibration; pneumatic flexible shaft coupling; semi-active

vibroisolation

1. INTRODUCTION

Development

and application of pneumatic flexible shaft couplings are in the center of our

department research activities for a long time [1], [2]. These couplings are

able to change torsional stiffness by changing pressure in their flexible

elements – air bellows. Mechanical drives with periodically alternating load

torque (reciprocating engines and compressors) are prone to resonance,

pneumatic flexible shaft coupling are ideal device for protecting them from

excessive torsional vibration. This article deals with a problem of avoiding

resonance state on an example of diesel engine – electric generator mechanical

drive.

2. EXAMINED MECHANICAL SYSTEM

The selected mechanical system

consists of a 10-pole synchronous generator driven by

a 6-cylinder diesel engine. This mechanical system works on a constant

operating speed resulting from the required electric network frequency. It is

necessary to use a flexible shaft coupling with a proper torsional stiffness to

avoid resonance. The technical parameters of mechanical system are as follows

[3]:

Parameters of engine:

·

Turbocharged

diesel line engine type ČKD

6-27,5 A2L

·

Nominal

power by 600 RPM: PM = 515 kW

·

Mass

moment of inertia: IM = 137 kg.m2,

Parameters of generator:

·

Synchronous

generator type SIEMENS

1FC2 561-10

·

Input

power: PG = 492 kW

·

Operating

speed: no = 600 RPM

·

Number

of poles: 10

·

Mass

moment of inertia: IG = 61,0 kg.m2

Parameters of shaft coupling:

·

Pneumatic

flexible shaft coupling type 4–1/310–T–C

·

Dynamic

torsional stiffness:

![]() N.m.rad-1 (1)

N.m.rad-1 (1)

where pp0 kPa is air pressure in the coupling

·

Mass

moment of inertia of one hub: I1S = I2S =

29,86 kg.m2

Static and dynamic torsional

stiffness of coupling depends on air pressure pp0 kPa.

3. TORSIONAL VIBRATION ANALYSIS

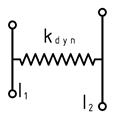

This mechanical system can be

considered as a two-mass torsional oscillating mechanical system, where the

first mass J1 consists of masses JM and J1S,

and second mass consists of masses J2S and JG

(Fig. 1).

Fig. 1. Two mass torsional

oscillating mechanical system

The major harmonic component of load

torque for a six-cylinder four-stroke reciprocating engine is the third

harmonic component, the minor harmonics are the integer multiples of half

harmonic component. Minor harmonic may occur only by uneven cylinder operation.

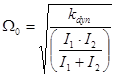

The natural frequency of mechanical

system can be computed as:

rad.s-1 (2)

rad.s-1 (2)

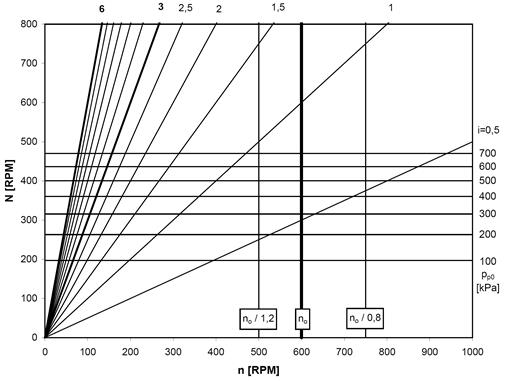

If resonance occurs during

operation, it can be determined from Campbell diagram (Fig. 2), where the natural frequencies in

RPM by different pressures (100, 200 ... 700 kPa) and harmonic frequencies of i-th

order are displayed. Where the frequency of torque harmonic is equal to natural frequency, a

resonance occurs.

Fig. 2. Campbell diagram of examined mechanical

system

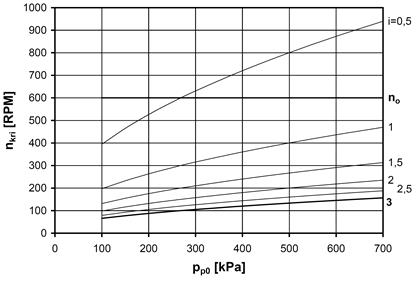

Speeds where resonances occur are

called critical speeds nkri. How critical speeds nkri

depend on pressure pp0 is displayed on fig. 3. By the

operating speed no = 600 RPM, only one resonance from 0,5-th

order may occur by pressure pp0 =264 kPa.

Resonance state is dangerous because

of increased torsional oscillation, which can damage the whole mechanical

system. According to several authors, the frequency ratio hi = w·i/W0 between i-th harmonics and natural frequency must satisfy the

condition: ![]() . On the

Campbell diagram (Fig. 1), no resonance should lie between no

/1,2 and no /0,8. The given mechanical

system can operate by pressures pp0=100, 500, 600 and 700 kPa.

By other pressures a resonance from 0,5-th order occurs near the

operating speed.

. On the

Campbell diagram (Fig. 1), no resonance should lie between no

/1,2 and no /0,8. The given mechanical

system can operate by pressures pp0=100, 500, 600 and 700 kPa.

By other pressures a resonance from 0,5-th order occurs near the

operating speed.

Fig. 3. Critical speeds, pressure graph

4. CONCLUSION

Based on

presented results, we can say that the natural frequency as well as critical

speeds of a torsional oscillating mechanical system can be tuned (changed) by

using a pneumatic flexible shaft coupling. Pneumatic flexible shaft couplings

are therefore considered not only as plain flexible shaft couplings, but

pneumatic tuners of torsional oscillation.

References

1. Homišin J. 2002. Nové typy pružných hriadeľových

spojok: vývoj, výskum, aplikácia. Košice: Vienala. ISBN 80-7099-834-2. [In

Slovak: New types of couplings flexible

shaft: development, research, application].

2. Kaššay P. 2008. „Optimalizácia torzne kmitajúcich

mechanických sústav metódou extremálnej regulácie”. PhD thesis. Košice:

Technical University of Košice. [In Slovak:

“Optimizing torsionally vibrating mechanical systems method Extremal Regulation”].

3. Kaššay P. 2014. „Modelovanie, analýza a optimalizácia torzne

kmitajúcich mechanických sústav”. Habilitation thesis, Košice: Technical

University of Košice. [In Slovak:

“Modeling, analysis and optimization torsionally vibrating mechanical systems”].

Acknowledgements: This paper was written in the

framework of Grant Project VEGA: „1/0688/12 – Research and application of

universal regulation system in order to master the source of mechanical

systems excitation”.

Received

23.10.2014; accepted in revised form 25.06.2015

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License