Karolina PROBIERZ[1]

Analiza zakłóceń w przepływach logistycznych w przedsiębiorstwie Branży MasZYN Górniczych

Streszczenie. W artykule zidentyfikowano i przeanalizowano zakłócenia, które występują w trakcie realizacji zadań transportowych i magazynowych. Wybrano zakłócenia występujące najcześciej w realizowanych procesach transportowych i magazynowych. W pracy przedstawiono także możliwe sposoby usprawnień występujących zakłóceń. Artykuł ma charakter praktyczny.

Słowa kluczowe: Przepływy logistyczne, analiza zakłóceń, procesy transportowo-magazynowe.

Analysis

of disturbances in logistic flows in MINING MACHINERY company

Summary. Disturbances that occur in the course of

transportation and storage tasks has been identified and analyzed. Disturbances

occurring the most frequently in the ongoing processes of transport and storage

have been selected. The article also shows possible ways of improvements of

occurring disturbances. The

article is of a practical nature.

Keywords: Logistics flows, analysis of

disturbances, transportation and warehousing processes.

1. INTRODUCTION

The internal warehouse transport

plays an important role in manufacturing companies (unit and small series

production) operating in the machine industry, as it is directly related to the

manufacturing logistics. This transport, in particular, involves movement of

products over small distances that are dependent on the spatial distribution of

the company as well as the so-called components of the infrastructure of the

production process and their locations. This transport includes movements both

within the area of warehouse facilities and between various facilities located

on the premises of the production plant.

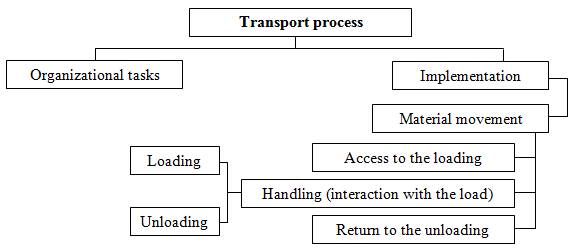

The main elements of the transport

process in a warehouse facility and outside of the warehouse facilities that

support the production process include:

Fig. 1. Major components of the transport process

Rys. 1.

Główne składowe procesu transportowego

Source: Own study based on [5].

The concept of transport processes

(internal) is meant as a transportation process from one place of the company

to another (production site, warehouse) [4,7].

Internal transport is closely related to the flow

paths of raw materials, finished products within a specific organizational unit

[6].

The shaping and selection of the

transport solution constitutes the key element of the management-related

issues, since the internal transport process within a company is one of the

main processes of logistical activity [1, 2]. Internal transport system [ITS]

is thus a binder that keeps together all the logistical processes in the

warehouse facility. Should such a system lose efficiency, the warehouse can be

paralyzed (stock shortages, delays, congestions, etc.), which may lead to a

shutdown of the entire supply chain. Therefore this system must be properly

designed and then monitored and evaluated. To that end, it is necessary to

develop appropriate ITS assessment methods in the warehouse facilities that

support production processes.

The internal transport is one of the most important additional processes in all the companies (service, manufacturing and production as well) Internal transport in all of these companies is responsible for the implementation of information and material flow. The implementation of information and material flows may be hindered by an interruption. The analysis of the interruptions in the implementation of the flows within production plants is a complex process consisting of several stages. It includes, among others, the identification of [3]:

-

the

location where the interrupting factor appears (e.g. the production line, a

particular workstation, a supplier, the transport system),

-

the

elements which cause interruptions (e.g. an employee, transport equipment,

machinery),

-

the

sources of interruption (e.g. shortages in the personnel or equipment, a malfunction,

shortages of materials, missing information, new urgent orders, late receipt of

materials),

-

the

deviations as the results of the interruptions,

-

the

losses related to the occurrence of the deviation (e.g. the lengthening of the

production cycle, excessive stock amounts).

The interrupting factors also

include all the unexpected events that have a destructive influence on the

implementation of the flows and which cause the balance or the goal of the

production plant activity to change. In order to identify interruptions in the

flows, one can take advantage of daily flow examinations within the company

using sheets in which the employees make notes about the interruptions on the

daily basis or e.g. the fish-bone diagram. For the search of the root causes of

the identified interruptions, one can use the 5Why approach.

2.

IDENTIFICATION

OF INTERRUPTIONS IN THE SELECTED COMPANY – DESCRIPTION OF THE METHOD

As a result of ongoing research

based on observation, interviews and interruption sheets, information on the

interruptions in the internal transport and warehousing systems were obtained.

For this reason, field studies aimed at identification of the most significant

interruptions were conducted in the selected company. The study used

interruption measurement sheets. The deviations in material flows were

categorized on a 3-step scale:

-

group

1: occurs rarely (once every a few months),

-

group

2: occurs occasionally (at least once a month),

-

group

3: occurs frequently (at least once a week).

The study was conducted over the

period of 3 months. Every day the internal transport and warehousing employees

got interruption measurement sheets, in which they took notes on the

interruptions. At the end of the shift, a researcher collected the sheets.

The interruption measurement sheet

is shown in table 1.

Table 1 Interruption measurement sheet |

|||

|

Date: |

Equipment utilization level during

the shift |

||

|

Factors No. |

Name of a factor |

Was there an interruption? (if

yes, put X) |

Number of occurrences (put an X

whenever there was an interruption) |

|

1 |

|

|

|

|

2 |

|

|

|

|

3 |

|

|

|

|

4 |

|

|

|

|

5 |

|

|

|

|

N |

|

|

|

|

Source: Own

elaboration |

|||

Two types of interruption

measurement sheets were developed. The first sheet applied to the interruptions

that occur in the transport between the warehouse facilities and the production

/ assembly halls as well as between the production halls and the assembly

halls), while the other applied to the transport directly in the warehouse.

Throughout the period of the study, 420 measurement sheets were handed out for

warehouse transport equipment and 480 measurement sheets were handed out for

the equipment used in transport outside of the warehouse.

3.

IDENTIFICATION

OF INTERRUPTIONS IN THE SELECTED COMPANY

Based on the observation and

interviews, groups of interruption factors were identified. For warehouse

transport, such a group consists of 44 factors that may influence the transport

in the warehouse facilities.

For the system of transport between

the company facilities, 38 transport interruptions were identified.

As a result of the research, the key

bottlenecks (interruptions) were identified in the internal and warehouse

transport process. The major bottlenecks were selected on the basis of an

analysis of the interruption measurement sheets. The major interruptions were

the ones that are most frequently mentioned, that is to say the ones that were

categorized within group 3 (interruptions that occur at least once a week). The

major interruptions that occur in the internal transport within a warehouse

facility include the interruptions presented in Table 2.

Table 2 The major interruptions that occur

in the internal transport in a warehouse facility |

|

|

Interruption type |

Interruptions |

|

Human realted |

Late notification about the demand

for a load unit leading to material handling equipment being occupied and the

incapacity to perform the order on time. |

|

Organizational |

Lack of planning for supplier

arrivals. It is only agreed that deliveries are to be performed before 12

noon. |

|

The necessity to wait for an MHE

that performs transport to the production or assembly hall. |

|

|

No direct access to a single load

unit (moving or unpacking) |

|

|

Technical and technological |

Lack of regularity in the

warehousing tasks (leading to accumulation of orders) as a result of the lack

of regularity in the production, |

|

Production cycle variability that

causes the completed orders to not be received. |

|

|

The need to use a ladder to

retrieve small-sized load units. |

|

|

The necessity to manually enter

data into a computer system |

|

|

Source: own elaboration |

|

These interruptions belong to group

3, so they occur frequently – at least once a week.

Identical studies were conducted for

the internal transport outside of the warehouse facilities. The findings of the

studies are as follows. The most frequent interruptions (bottlenecks) are the

interruptions presented in Table 3.

Table 3 The

major interruptions that occur in the internal transport of the warehouse

facilities |

|

|

Interruption type |

Interruptions |

|

Organizational |

Excessive number of routes from

the initial part assembly hall to semi-finished product warehouse facility

for the purpose of transporting into the unit assembly hall. |

|

Waiting with the material for a

warehouse MHE. |

|

|

Technical and technological |

The production cycle variability |

|

Lack of regularity in the

warehousing tasks (leading to accumulation of orders) as a result of the lack

of regularity in the production |

|

|

The size of the load makes unloading

the material more difficult, which causes waiting for the material handling

equipment |

|

|

The weight or dimension that makes

it impossible to transport more than one load unit at a time |

|

|

Exhausted transport infrastructure |

|

|

Source: own elaboration |

|

As can be seen, a large number of

interruptions are the same for both warehousing and internal transport tasks.

The employees of the company pointed to the same factors. The study also

determined the average utilization level for the internal transport and warehousing equipment, which was 83% and 85% for

warehouse transport and internal transport, respectively.

4. SUMMARY

As part of the study based on the

interruption measurement sheets, the most frequent interruptions were

identified, which were then discussed among experts in order to attempt to

address the identified problems. The final rationalization and improvements

applied to these interruptions that can be considered controllable from the

point of view of internal and warehouse transport and do not entail production

changes.

Some of the identified interruptions

are closely related to the nature of the company, more specifically to the

characteristics of the production process that takes place in it. The timing

and parameters of the internal / warehouse transport process are results of the

type of production. Unit and small series production is characterized by a high

level of randomness, thus it is impossible to eliminate interruptions, such as:

-

lack

of regularity in the warehousing tasks as a result of the irregularity in the

production,

-

production

cycle variability that causes the completed orders to not be received,

-

late

notification about the demand for a load unit leading to material handling

equipment being occupied and the incapacity to perform the order on time.

Additionally, due to the character

of the devices produced in the studied company, it is similarly impossible to

eliminate the following interruption: weight or dimension that makes it

impossible to transport more than one load unit at a time.

The last of the most frequent

interruptions for which no improvements were attempted to be made is the

exhausted transport infrastructure. The current state of the transport

equipment, according to the maintenance department, does not constitute a major

issue that could cause the bottlenecks to appear in the process. Any

malfunction that takes place in the equipment is repaired very quickly.

Furthermore, the plant has some additional transport equipment, which can be

used to replace the existing equipment in the event of a major failure that

could render a quick repair impossible. In the current situation, the

investment in a new transport infrastructure is not supported by a business

necessity and the profitability of the investment. The company plans to replace

the transport infrastructure in the future, though, in line with the adopted

strategy and performance supervision plan for these devices. All the

interruptions that were not discussed are very poorly controllable from the

viewpoint of the internal and warehouse transport.

The following was proposed to help

resolve the existing interruptions:

-

elimination

of the manual data insertion into the IT system during the goods-in or

goods-out process in the warehouse facilities through application of bar codes,

-

elimination

of the manual labor during the warehousing tasks (a ladder in the closed

purchasing warehouse facility),

-

implementation

of the Kanban system for warehousing processes for the standard products of the

company (universal – without the implemented structural and technological

changes of the product),

-

introduction

of appointments for suppliers in order to eliminate the accumulation of the

warehousing tasks,

-

authorizations

for internal transport operators in the semi-products warehousing facility to

unload semi-products in the goods-in area,

-

installation

of a hoist in the production halls to enable unloading of heavy items without

waiting for overhead cranes.

Bibliography

1. Abt S. 2001. Logistyka w teorii i praktyce. [In Polish: Logistics in theory and practice]. Poznań: Wyd. AE.

2. Abt

S., H. Woźniak. 1993. Podstawy logistyki.

[In Polish: Fundamentals of logistics]. Gdańsk: Wyd.

Stella Maris

3. Kramarz

W. „Model sterowania przepływami materiałowymi w sieci produkcyjnej”. [In Polish: “Model control the

material flows in the production network”]. In ZN Politechniki Śląskiej, seria: Organizacja i Zarządzanie 60:

153-163.

4. Kozłowski

R. (red.). 2009. Podstawowe zagadnienia współczesnej logistyki. [In Polish: Basic issues of modern

logistics]. Polska, Kraków: Wolters Kluwer.

5. Lissowska

E. (red.). 1975. Technologia procesów

przewozowych w transporcie samochodowym. [In Polish: Technology of

transport processes in road transport]. Warszawa: WKŁ.

6. Ładoński W. 1994. Podstawy towaroznawstwa ogólnego. [In Polish: Fundamentals of general commodities]. Wrocław: Wydawnictwo Akademii Ekonomicznej.

7. Probierz

K., A. Sładkowski. 2014. „Use

of the internal transport systems in the process of warehousing”. In Современный город: проектирование, строительство и развитие. Материалы международной научно-практической конференции по строительству и архитектуре: 158-166. УрФУ. Екатеринбург. [Sovremennyjj gorod:

proektirovanie, stroitelstvo i razvitie. Materialy mezhdunarodnojj

nauchno-prakticheskojj konferencii po stroitelstvu i arkhitekture: 158-166.

UrFU. Ekaterinburg].