Kirill VOINOV[1]

HOW TO DIMINISH THE WEAR FOR CHAINS WHICH ARE

TIGHT ON THE SPROCKETS

Summary. The speech in this article is going

about the standard bush-roller chain for bicycle, machine-tool or for conveyor.

And the chain can be settled in the different spatial position, namely in

vertical, horizontal or in the slope. In all these cases we have to stretch the

chain periodically because of wear during the operation. For this aim the

people apply different contact methods: spring-loaded rollers, flat springs (as

a pair of friction), stretchers and so on [2, 3]. But here we describe a new

way how to stretch the chain constantly and without any additional pairs of

friction at all [1, 2, 3] using only magnet. It simplified design and enhanced

the resistance against wear essentially.

Keywords: Bush-roller chain, sprocket, stretchers

Jak zmniejszyć zużycie łańcuchów, które ciasno przylegają do ZĘBATKI

Streszczenie.

W tym artykule mowa będzie o

standardowym tulejkowym łańcuchu dla rowerów, obrabiarek lub do ciągnienia.

Łańcuch może być osadzony w różnej pozycji przestrzennej, czyli w pionie,

poziomie lub po skosie. We wszystkich tych przypadkach trzeba rozciągać łańcuch

okresowo, ze względu na zużycie w czasie eksploatacji. Do tego celu ludzie

stosują różne metody kontaktowe: wałki sprężynowe, sprężyny płaskie (jako parę

tarcia), napinacze i tak dalej [2, 3]. W artykule opisano nowy sposób, jak

rozciągać łańcuch stale oraz bez użycia dodatkowych par tarcia [1, 2, 3] jedynie

przy użyciu magnesu.

To istotnie uprościło konstrukcję oraz zwiększyło odporność na zużycie.

Słowa kluczowe: Łańcuch, zębatka, napinacz

1. INTRODUCTION

In up-to-date machines, mechanisms, different

equipment there are various working elements or the whole junctions which

during many years didn’t have any alterations in their design, very likely,

with the exception of technology to manufacture the parts. For example, let’s

take the standard bush-roller chain for bicycle or for conveyor. It is

stretched and put on the sprockets. In practice the next important and main

characteristics can be changed: the long of the chain, pitch, mass, the

distance between sprockets, diameters, number of tooth and members, number of

the lines, power and high-speed factors, peculiarities of tension and

lubrication.

As a tradition way of the relative position for

sprockets is their vertical strengthening on the axis. In the capacity of the

tension device (stretcher) we usually use the spring-loaded rollers mounted on

their axis with frictionless bearings or sprockets, and seldom they are the

flat springs. Moreover we can draw a chain by means of the spiral working principles which are

accommodated in the special grooves. In these cases it demands for the most of

these mechanisms the manual adjustment by means of the transference of the

stretchers in the slots.

Although these named principles have been using

for a long time, they are rather complicated during manufacture, have not high

reliability for operation, forms the additional pairs of friction and wear out

the chains.

During operation process a chain always has its

natural wear and tear, the chain becomes longer that’s why the angle of the

girth for the tooth will be smaller. It reinforces the vibration and

oscillations. In its turn this situation changes the distribution of efforts

and strains both in chain and in tooth of sprockets. If the tension for the

chain will be too weak, the chain can jump off the sprockets at all. In this

case it brings to damage or even to fracture of our mechanism.

And what is more in practice we have a large

problem with chains if they are placed in

a horizontal position. In this case the wear for chain and sprockets grows

repeatedly and essentially. The point is that in such situation the sagging of

chain doesn’t useful both for chain and for the tooth of sprockets because of

their intensive wear. Our practice in operation of many chains shows that the

wear and tear we can see not only on the surfaces of tooth but on the “body” of

sprockets also.

2. METHODOLOGY OF

EXAMINATION

That’s why

the described situation it is needed to consider as the great problem. In this

article we show the new and very simple/effective method how to solve it (Fig.

As it was

mentioned above, if there are special rollers or sprockets to stretch the

chains we use bearings in a design, apply lubricant in which any abrasive can

get in it during operation. It leads both a spoiling for lubricant and wear for

bearing.

The same

negative pictures we can see if we use in the design the spring plates.

In my way

the all named negative moments connected with chains and sprockets accommodated

in various space position (vertical, horizontal or with a slope) were deleted

in full.

For

example, at the vertical arrangement of the chain (Fig. 1) the effective

tension for the links of chain we reach by means of constant magnet 4. The

presence of the block with

a screw helps us to regulate the position of our (constant or even electrical)

magnet both in vertical and in horizontal disposition because the block is

placed in a guide.

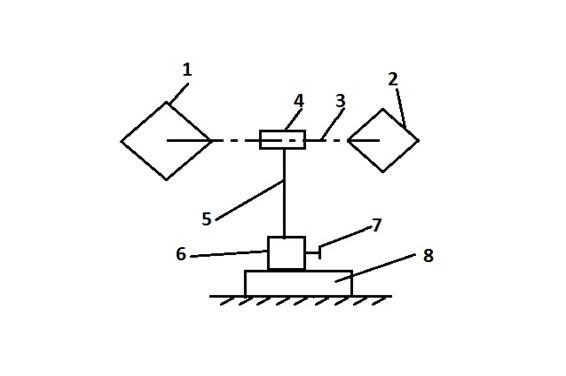

Fig. 1. Example

how to realize the pull for the chain without any contact with it: 1 and 2 –

sprockets;

3 – chain (for example, bush-roller); 4 – magnet; 5 – vertical support; 6 –

block; 7 – keeper screw; 8 – basis

Rys. 1. Przykład jak zrealizować naciąg łańcucha bez

jakiegokolwiek kontaktu z nim: 1 i 2 – zębatki; 3 – łańcuch (na przykład, tulejkowy);

4 – magnes; 5 – podpora pionowa; 6 – blok; 7 – śruba gwintowana; 8 – podstawa

If the

chain is very long, we can set up two magnets on the definite distance between

two sprockets. In any case the magnet makes for the larger girth of sprockets

tooth; automatically and constantly tighten the chain during operation deleting

all negative aspects named above.

If the

chain has the horizontal disposition, we use two magnets once again but set up

magnets quite near to the sprockets above of the two lines of a chain. By this

way we raise slightly the two lines of a chain at the same time and hold the

chain in such position

constantly. Using this way we axise both chain and sprockets and it is very

important. In this position our mechanical system will work without any

distortion (Fig. 2).

In our

experiment we have used the standard bush-roller chain for bicycle. The

distance between axes of sprockets was

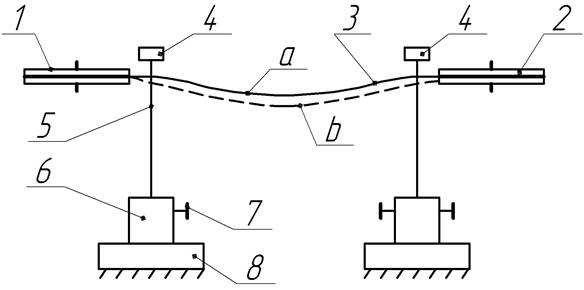

Fig. 2. Schematic

version of a distribution sprockets and magnets which raise slightly the two

lines

of a horizontal chain simultaneously: 1 and 2 – sprockets; 3 – chain (for

example, bush-roller); 4 – magnet; 5 – vertical support; 6 – block; 7 – keeper

screw; 8 – basis; а – the disposition of

a chain if we use magnets; б – sagging of a chain if the magnets are

absent (the old traditional/standard sketch of assembling)

Rys. 2. Schemat

rozkładu kół zębatych oraz magnesów, które jednocześnie nieznacznie zwiększają dwie

linie poziome łańcucha: 1 i 2 – zębatki; 3 – łańcuch (na przykład, tulejkowy);

4 – magnes; 5 – podpora pionowa; 6 – blok; 7 – śruba gwintowana; 8 – podstawa;

a – dyspozycja łańcucha, jeśli używamy magnesów, b – ugięcia łańcucha jeśli

magnesy są nieobecne (stary tradycyjny/standardowy szkic montażu)

Using such

method of assembly for chains we decrease wear of chains and sprockets,

vibrations, strain in parts, and the design becomes cheaper and has high

reliability in operation. Moreover the experiment shows that the sagging of the

chain doesn’t take place at all in a position for magnets near the sprockets.

So in this case the coefficient of sagging will be 1 (instead of 6 for

horizontal transmissions and 3 if the slope has ≤ 40o). For

the preliminary tension F0 of chain from the excessive sagging they

use the next formula:

F0 = Kf q a g [N]

(1)

where:

Kf – is the coefficient of sagging;

q – mass of

a – the distance between axes of

sprockets, [m];

g – acceleration (9,81 [m/s2]).

Thus, in our

case if we have got the horizontal position, the chain and sprockets raise

slightly, and the coefficient of sagging will be 1 (as in a vertical position

for chain and sprockets).

What kind of picture

we can observe if the chain and sprockets have the vertical position? Put our

magnet in the space between of the two lines of chain (Fig. 3). In this case

the both lines of chain have been attracting by magnet to each other constantly

during the all cycle of operation and they encompass of sprockets better.

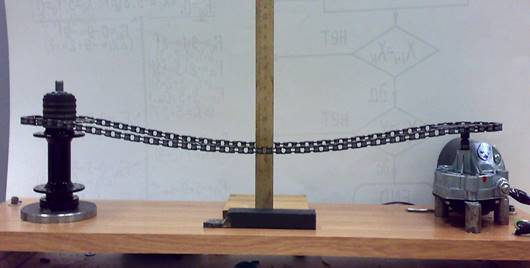

Fig. 3.

The demonstration of setting for the magnet using special test bench

Rys.

3. Ustawienie magnesu za pomocą specjalnego stanowiska testowego

In the

process of deterioration both the chain and sprockets, and stretching or

lengthening of a chain our magnet will always attract both lines of chain.

Another positive result of my observation in this case is the next: about one

additional tooth will be encompassed by

pitch of the chain, that’s why it works much better with magnet. The

rapprochement for the two lines of chain was about

If the

distance between sprockets are big, set two or three magnets between the lines

of chain. They will calm the vibration of the oscillation, too.

Now here

it is the picture which demonstrates us the real shape of chain and sagging in

a horizontal position with sprockets (Fig. 4 and Fig. 5). We made the experiment

using special test bench.

Fig. 4.

Laboratory stand to investigate chains and sprockets if they have a horizontal

disposition

Rys.

4. Stanowisko laboratoryjne do zbadania łańcuchów i zębatek dla ustawienia

poziomego

Fig. 5. Other

foreshortening when we can see as the magnet raised slightly the line of the

chain and put it in one plane with sprocket

Rys. 5. Inne

zniekształcenia, gdy możemy zobaczyć jak magnes podniósł nieznacznie linię

łańcucha oraz umieścił go w jednej płaszczyźnie z zębatką

Post-graduate

student S.V. Gusev executed many investigations connected with the new

technical decision. Namely, he carried out three experiments with each version:

1) for vertical position of the

bush-roller chain both without magnet (but with a standard version with two

rollers and a spring) and with a magnet, too;

2) for the horizontal disposition of the two sprockets both without

magnet (traditional way) and with magnet (this new method);

3) for slope with 45o.

And we had

got the next results. We managed to delete the additional pairs of friction

(two rollers, two shafts, four bearings), spring and lubricant at all. In this

case we needn’t to stretch the chain periodically (it fulfils our magnet

constantly). Moreover in this case the wear of chain was diminished till 3.9%

on average against of the standard design. For slope position using magnet we

decrease the wear more than 3 times. We decrease both vibration and the wear of

the chain till 8% (on average) against the standard design. For horizontal

position of disposition for sprockets using magnet we diminished the rate of

wear till 5.2 times against of the standard design (without magnet).

Warning:

any persons cannot use this technical novelties in practice to get any profit.

It can be done only after the financial contract of permission/agreement for

this signed by author K.N. Voinov. All rights are reserved.

3. EXAMINATION RESULTS AND

CONCLUSION

So, we

have got the new way to decrease essentially wear and tear for chains and

sprockets in their different space disposition (vertical, horizontal or with a

slope). This way helps to increase the reliability and durability both for

chains and sprockets during their operation.

Bibliography

1.

Патент

№2480367 по заявке

№2011124693

приоритет от

16 июня 2011. Натяжитель

цепи. Войнов К.Н.

зарегистрировано

в Госреестре

РФ 27 апреля 2013. [Patent №2480367 po zajavke №2011124693 prioritet ot 16 ijunja 2011. Natjazhitel cepi. Vojjnov K.N. zaregistrirovano v Gosreestre RF 27 aprelja 2013]. [In Russian: The patent application

№2480367 for №2011124693 priority of June 16, 2011. The chain tensioner. Voinov KN

registered in the State Register of the Russian Federation April 27, 2013].

2.

Yamamoto Ken, Eiji Maeno. 2001. „Chain tensioner”. JP2001355691(A):

12-26.

3.

Yoshikazu Nakano, Kunimatsu Kohei. 2011. “Chain tensioner”. Jp20110256970.

4.

Markley

George L., James Capp, Mark M. Wigsten. 2009. Long mechanical tensioner with a compliant blade spring. US7597640.