Article

citation information:

Khabiri, M.M., Afkhamy Meybodi, P.,

Montazeri, A.M. Evaluation of the effect of various surficial pollutants and

environmental condition on surface friction performance of road pavement. Scientific Journal of Silesian University of

Technology. Series Transport. 2021, 112,

99-111. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.112.7.8

Mohammad Mehdi KHABIRI[1],

Pooya AFKHAMY MEYBODI[2],

Ali Mohammad MONTAZERI[3]

EVALUATION

OF THE EFFECT OF VARIOUS SURFICIAL POLLUTANTS AND ENVIRONMENTAL CONDITION ON

SURFACE FRICTION PERFORMANCE OF ROAD PAVEMENT

Summary. Skip resistance of

asphalt is an important parameter that can influence the safety of drivers on

roads. Although there is a linear relationship between slipping on road

surfaces and accidents, the impacts of pollutants for decreasing friction of

roads is clear to researchers. Moisture and temperature influence friction and

safety. In this research in SMA

samples, three different gradations with the maximum nominal sizes of 19, 12.5

and 9.5, based on international standards were used. For polluting the surface,

five materials that are found on roads were used, including fine-grained soil,

sand, oil, soot and rubber powder. To measure the skip

resistance, the British pendulum tester was used and for analysing

macro-texture, the sand patch method was used. The results of this research

showed that by increasing the maximum nominal size of aggregates, the depth of

macro-texture in surfaces are grown and this is due to the decrease of fine

aggregates in larger gradations. Because of the higher flexibility of pure bitumen,

the applied compression pressure on rigid aggregates can cause indentations in

the substrate and result in declining the roughness height of aggregates in the

mixed surface. This leads to declining the hysteresis part of friction by

increasing temperature.

Keywords: road safety, skid resistance, pollutants,

British pendulum tester, decision tree

1. INTRODUCTION

Every day

around the world, road accidents occur. Driver errors, poor transportation

system and poor road infrastructure contribute to these accidents [1-5].

Accumulated pollutants on roads surfaces decrease skid resistance significantly

and increase the risk of accidents. Skid resistance of asphalt is a crucial

parameter that affects the safety of drivers. Additionally, there is a linear

relationship between slippery road surfaces and accidents [6]. In the dry

season, road surfaces have sufficient skid resistance, however, in the winter

skid resistance is reduced when the surface of the road is covered with mud,

snow, ice, etc. Environmental situations are largely influential in skid

resistance between road and vehicle wheels. When the

surface of roads are covered, skid resistance is influenced significantly [7].

The

increase in the number of accidents after the first rainfall during a dry

period is due to the existence of particles on road surfaces (dust, rubber

debris, exhaust fumes, equipment, etc.) [8]. It seems

that the accumulated particles during the dry periods and water from the first

rain create a mixture of high viscosity and decreases friction [9]. Fine

particles from the road, rubber debris or traffic and dispersion of industrial

materials can be the source of safety issues such as accidents on the first day

of rain after a dry period or season change of skid resistance [10]. This

article provides an experimental study under a controlled situation, analysing

the accumulation of particles and cleaning by flow and surface water.

2. REVIEWING SOURCES

Wilson [11] observed that friction ratio decreases significantly at the

beginning of rain (pollution stage), and then upon reaching a stable amount

(cleaning stage) it increases. Kulakowski and Harwood [12] showed that a water

layer with 0.025 thicknesses on road surfaces can

decrease friction by 75%. The fine particles on roads are recognised as an additional element that declines the wet friction.

Lambourn and Viner [13] experimented with different waste materials (clay,

sand, etc.) on the road surface and they realised that when the surface of

roads are polluted, friction ratio decreases strongly in comparison with a dry

situation. Moreover, other researchers found out that these particles can

result in the lubrication of road surfaces. Li et al. [14] investigated the

friction between shoes and surfaces and they discovered that particles can

decrease friction even in dry situations. Although, with increase in particle

sizes, friction ratio decreases. Mills et al. [15] studied dry surface friction

covered with waste particles and it was found that the critical size of

particles is about 50-60 µm. When a rubber layer is slipped on the

surface, the larger particles than the critical size, slip on each other.

However, particles with lower size than the critical size, stick to each other

because of stitches force and they result in a slippery behaviour between the

surface and the rubber. On the other hand, surface roughness can trap some of

the particles, preventing particle passage from the surface bulge, resulting in

cutting the particle layer.

Heshmat [16] showed that solid particles can make a thin layer of

lubricant, which behaves like a thin layer of fluid. For a complete perception

of the effect of precipitated particles on the friction of tyre and road, then

we need to investigate the dry situation.

In another research by Hichri [17], the influence of fine particles on skid

resistance was investigated. In this research, a British pendulum tester was

used for friction measuring. Surfaces with rough and eroded aggregates were

studied. In addition, a container was used for the simulation of rain that controlled the sprayed water on the surface of the

sample. It was defined that friction recovery in dry and wet situations for

eroded aggregates was slower than rough aggregates. Based on this study,

friction and mass of particles are changed similarly but in adverse direction.

This means that when the mass of particles is decreased,

friction is increased. There is a mass threshold, above it, friction is low and

approximately stable but under this threshold, the friction increases due to

direct contact between surface roughness and rubber tyre.

This article advances previous studies with new data and friction

experiments from the application of SMA

asphalt on road surfaces. In the first section, the experiments are described

based on particles properties, type of pollutants and method used. In the

second section, the results of friction experiments in different temperatures

and moistures are provided. Then the analyses with different statistical

approaches are implemented in the third section and the effect of facial

wetness, fine-grained texture and pollutants are surveyed on friction.

3. MATERIALS

3.1. Aggregate and Bitumen

In this

research for SMA samples, three

different aggregates with maximum nominal sizes of 19, 12.5 and

9.5 mm based on NCHRP 9-8 were used. Also, the aggregates are made of lime.

Table 1 and Figure 1 show the definition of these gradations. The physical

properties of aggregates are listed in Table 2. For preparing samples, pure

60-70 bitumen was used, and its properties are given in Table 3.

Tab.

1

Gradation of SMA by NCHRP

|

Sieve

size (mm) |

Maximum

nominal size |

||

|

9.5 mm |

12.5 mm |

19 mm |

|

|

25 |

- |

- |

100 |

|

19 |

- |

100 |

95 |

|

12.5 |

100 |

95 |

62 |

|

9.5 |

95 |

52 |

42.5 |

|

4.75 |

43 |

24 |

24 |

|

2.36 |

24 |

20 |

20 |

|

1.18 |

17 |

17 |

17 |

|

0.6 |

15 |

15 |

15 |

|

0.3 |

13.5 |

13.5 |

13.5 |

|

0.075 |

9 |

9 |

9 |

Fig. 1. Gradation of aggregates

Tab.

2

Physical properties

of aggregates

|

Experiment |

Standard

|

Results

|

|

Coarse

aggregate specific gravity (gr/cm3) |

ASTM

C127 |

2.68 |

|

Fine

aggregate specific gravity (gr/cm3) |

ASTM

C128 |

2.58 |

|

Sodium sulfate

soundness (%) |

ASTM C88 |

2.5 |

|

Los

Angeles abrasion value (%) |

ASTM

C131 |

25.2 |

|

Sand

equivalent (%) |

ASTM

T176 |

63 |

|

Flakiness

(%) |

BS-812 |

15.78 |

Tab. 3

Properties of used

bitumen

|

Experiment |

Temperature

of experiment (°C) |

Standard

|

Results

|

|

Penetration

(0.1 mm) |

25 |

ASTM D5 |

65 |

|

Ductility

(cm) |

25 |

ASTM

D113 |

106.3 |

|

Specific

gravity (gr/cm3) |

25 |

ASTM D70 |

1.013 |

|

Softing

point (°C) |

- |

ASTM D36 |

54.3 |

|

Flash point (°C) |

- |

ASTM D92 |

304 |

|

Rotational

viscosity (mPa.sec) |

135 |

ASTM

D4402 |

436 |

3.2. Pollutants

In this

research, five common and most important pollutants that are seen on road

surfaces with low seasonal rainfall and deserts were used for the simulation.

These pollutants are fine-grained soil, sand, oil, soot and rubber powder and

are shown in Figure 2.

Fig. 2.

Various pollutants used in this research

4. PREPARATION OF SPECIMENS

In this

research, preparing the samples were implemented in two stages. In the first

stage for determining the optimum bitumen content, samples based on the

following standards were made and tested: bulk specific gravity (ASTM D2726),

stability and flow (ASTM D1559), and the maximum theoretical specific gravity

(ASTM D 2041). For compressing the SMA

samples, 50 impacts of Marshal Hammer were used [18]. The optimum bitumen

content for different gradation is listed in Table 4.

As shown

in Table 4, by decreasing the nominal size, the optimum bitumen content

increases. In the second stage, SMA

samples were made based on the ASTM D5581 standard with 6 inches (15 cm)

diameter for the skid resistance experiment (Figure 3).

Tab.

4

Optimum bitumen

content of SMA samples

|

Maximum

nominal size (mm) |

Optimal

pitch percentage (%) |

|

9.5 |

6.5 |

|

12.5 |

6.3 |

|

19 |

6.14 |

Fig. 3.

SMA sample with 6 inches diameter.

5. PREPARATION OF SPECIMENS

5.1. Measuring friction

In this

research, the British pendulum tester (BPT)

was used for measuring friction. This device was designed by the Road Research

Laboratory (RRL), and it is one of

the simplest devices for measuring skid resistance since 1960. This method is

described in the ASTM E303 standard.

This device has a rubber slipper at the end of its arm, which slips on

the surface and measures friction. The measured values (Britain pendulum number

– BPN), shows the skid

resistance of the surface, and it is between 0 and 150. A larger BPN shows

higher skid resistance. For experimental samples, the dimensions of the rubber

slipper are 6*25*76 mm and the length of slip is between 124 and 127 mm so that

the 6 inches (15 cm) samples cover this length [19]. Before every experiment,

this rubber slipper should pass five times on the aggregate surface. This

operation results in removing the sharp edges of the rubber slipper before

every experiment [17].

5.2. Sand Patch Method

One of the

most common methods for measuring the macro-texture of pavement surfaces is the

sand patch method described in the ASTM E965 standard. In this method, a

certain volume of standard sand is dispersed on a dry and clean surface in a

circular shape. The level of dispersed sand should be at the same level of the

top point as aggregate, and then the diameter of the cycle is measured. The

mean texture depth (MTD) is

calculated by dividing volume by cycle area as follows [19]:

(1)

(1)

Where:

MTD= the mean texture depth (mm),

V= sand volume (mm3),

D= average of cycle diameter (mm),

As the MTD is larger, the surface is rougher.

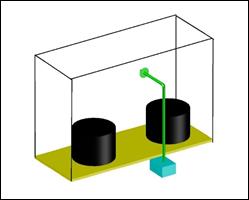

5.3. Simulating rainfall

One

simulator for rainfall was implemented for controlling the water splash on the

surface of the sample. This system included a rectangular container (20*30*40

cm) and a nozzle attached to a water pump that stored a stable flow of water

and made small drops (Figure 4). This system can simulate high and low

rainfalls (low water volume and the surface remained viscose and

slippery).

Fig. 4.

The simulating rainfall container

6. RESULTS

For the

sand patch experiment, for every asphalt mixture, two samples were made, and

every sample was experimented twice. Figure 5 shows the average amount of sand

patch. As seen, by increasing the maximum nominal size of aggregates, the depth

of macro-grained texture increases, and this is due to decreasing the amount of

fine aggregate in the larger gradation. As MTD

increases, the drainage of surface water happens more rapidly, and friction

increases at the end.

Fig. 5.

The result of sand patch

Figures

6-8 illustrate the variation of the sample's friction in dry and wet situations

for three gradations. As expected, friction in a dry state is higher than in a

wet state. As witnessed, the highest loss of friction was seen in oily

pollutants. Because oil is an insoluble liquid, when it mixes with water, a

thicker layer is created on the surface, which leads to more decrease in

friction.

Fig. 6.

The comparison of BPN in dry and wet

situations for samples with 9.5 mm aggregates

Fig. 7.

The comparison of BPN in dry and wet

situations for

samples with 12.5 mm aggregates

Fig. 8.

The comparison of BPN in dry and wet

situations for samples with 19 mm aggregates

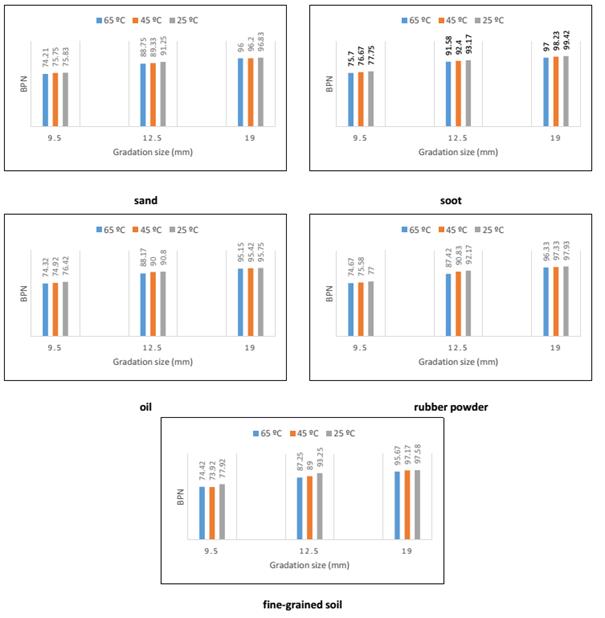

Figure 9

shows the variation in the BPN amount

based on gradation and type of pollution. As noticed, by increasing the maximum

nominal size of aggregates, sample's friction rises due to MTD increase. In addition, the lowest amount of BPN in every gradation relates to

fine-grained soil. In samples with maximum nominal sizes of 9.5 and 12.5 mm, the highest amount of BPN is related to soot pollution but in

the sample with the highest nominal size, 19 mm, the biggest amount BPN is for rubber powder.

Fig. 9.

The gradation variation based on type of pollutant

Figure 10 shows the BPN amount

for three different temperatures (25, 45 and 65°C). As seen, by increasing

the temperature of the experiment, the BPN

amount decreases in all plots of the Figure. This effect can be attributed to

variation in bitumen stiffness in addition to variations in water viscosity on

the surface of the sample. These two factors can be effective in both

hysteresis and adhesion. Since the mixture of asphalt in the surface of

pavements and rubber tyre from vehicles are viscoelastic materials, temperature

affects the friction properties. Stiffness of the slider in the British

pendulum tester and bitumen decreases with the increase in temperature. As

temperature increases, total loss energy in vehicle wheel for deformation

decreases, and finally the hysteresis part declines for a certain amount of

shape change. Moreover, because of more flexibility in higher temperature, the

applied compressive pressure on rigid aggregates can cause indentations in the

substrate, thus reduce the roughness height of aggregates in the surface of the

mixture. This phenomenon helps to decrease the hysteresis part of friction with

temperature rise. The adhesion part of friction is influenced by the change in

the hydrodynamic properties of water with temperature change. Shear stress in

Newtonian fluids such as water depends on viscosity and strain time rate. As

viscosity decreases with temperature rise, shear stress drops and finally the

adhesion part of friction decreases [20].

7. DECISION TREE

The

decision tree method is one of the ways for classifying data and it is a subset

of the numerical taxonomy method. The decision tree is a method of

non-parametric data analysis; it is a powerful tool for predicting and

classifying problems. In this method, the result of data analysis is shown

graphically, making the tree easier to understand and interpret. Using the

decision tree, important and insignificant variables can be identified and

eliminated. The decision tree consists of several nodes. In Figure 11, the zero

node, which is the root and the first node, shows the amount of friction (BPN). This node is divided into three

branches. This indicates that the most important variable affecting the BPN value is the size of the aggregates.

As observed, when the aggregate size is 19 mm, the largest amount of friction

was obtained (42.1% of the largest BPN

is for samples with a maximum size of 19 mm). Each of

its 1 to 3 nodes is divided into 2 separate nodes. This phenomenon shows that

after the maximum size of aggregates, the variable of water content on the

surface of the samples is the most important factor affecting the amount of BPN. As seen, there is more BPN in low rainfall than in heavy

rainfall. This phenomenon is true for all three gradations. Samples with a size

of 19 mm have the highest amount of BPN,

which is due to the rapid drainage of rainwater. Further, Node 6 is divided

into three branches. This shows that temperature has the greatest effect on the

samples with 12.5 aggregate size with low

precipitation. As temperature increases, the amount of friction increases,

which is expected.

Fig. 10.

The plot of friction change by temperature

Fig. 11.

The decision tree of pollutant impact and environmental factors on friction

8. CONCLUSION

1-

By increasing the maximum nominal size of aggregates, MTD of pavement increases due to decline

in fine particles in higher granules.

2-

The maximum friction loss is for oil pollution. Because

oil is an insoluble liquid, when mixed with water, it creates a thicker layer

on the surface that further reduces friction.

3-

By increase in the maximum nominal size of aggregates,

friction of the samples increases and this is because of increase in MTD.

4-

The minimum amount of BPN

in every three gradation is for fine-grained soil. In samples with a maximum

nominal size of 9.5 and 12.5 mm,

the highest amount of BPN is related

to soot pollution, but in the case of samples with a maximum nominal size of 19

mm, the highest amount of BPN is

related to rubber powder.

5-

The amount of friction decreases with increasing the test

temperature. This effect can be due to changes in bitumen hardness plus changes

in the viscosity of water on the surface of the sample, which can affect both

hysteresis and friction adhesion.

6-

Because of the higher flexibility of bitumen at higher

temperatures, the compressive pressure applied to the rigid aggregate can cause

indentations in the substrate and finally reduce the roughness height of the

surface aggregates. This phenomenon also helps to reduce the hysteresis

component of friction by increase in the temperature.

7-

Based on the decision tree, the most important factor

influence on friction is the size of the aggregates. In addition, the second

factor that has the most significant effect on friction is the amount of water

on the surface of the samples.

References

1.

Ibrahim

M. Asi. 2007. „Evaluating skid Resistance of

different asphalt concrete mixes”. Building

and Environment 42: 325-329. DOI: https://doi.org/10.1016/j.buildenv.2005.08.020.

2.

Farooq

Danish, Janos Juhasz. 2020. „Statistical Evaluation of Risky Driver

Behavior Factors that Influence Road Safety based on Drivers Age and Driving

Experience in Budapest and Islamabad”. European Transport \ Trasporti Europei 80(2): 1-18.

ISSN: 1825-3997. DOI: https://doi.org/10.48295/ET.2020.80.2.

3.

Mohanty

Malaya, Partha Pratim Dey, Bhagyashree Panda. 2020. „Assessment of

traffic safety at median openings using surrogate safety measures: a case study

in India”. European Transport \

Trasporti Europei 80(3): 1-12. ISSN: 1825-3997.

DOI: https://doi.org/10.48295/ET.2020.80.3.

4.

Hichim

Majid Farag, Ahmed Shany Khusheef, Saddam Hasan Raheemah. 2020.

“The Effects of Driver Age and Gender on Vehicle Stopping Distance Under Different Speeds”. European Transport \ Trasporti Europei 80(1): 1-11. ISSN 1825-3997.

DOI: https://doi.org/10.48295/ET.2020.80.1.

5.

Staniek

M., P. Czech. 2016. “Self-correcting neural network in road pavement

diagnostics”. Automation in

Construction 96: 75-87.

DOI: 10.1016/j.autcon.2018.09.001.

6. Reginald B. Kogbara, Eyad A. Masad, Emad Kassem, A. Tom Scarpas, Kumar Anupam. 2016. „A state-of-the-art review of parameters influencing measurement and modeling of skid resistance of asphalt pa vements”. Construction and Building Materials 114: 602-617. DOI: https://doi.org/10.1016/j.conbuildmat.2016.04.002.

7. Lubis A.S, Z.A Muis, E.M. Gultom. 2018. „The effect of contaminant on skid resistance of pavement surface”. In: IOP Conference Series: Earth and Environmental Science 126. DOI: doi:10.1088/1755-1315/126/1/012040.

8.

Eisenberg

Daniel. 2004. „The mixed effects

of precipitation on traffic crashes”. Accident analysis & prevention 36(4): 637-647.

DOI: https://doi.org/10.1016/S0001-4575(03)00085-X.

9.

Persson

B.N.J, U. Tartaglino, O. Albohr, E. Tosatti. 2005. „Rubber friction on

wet and dry road surfaces: The sealing effect”. Physical Review B 71(3): 035428.

DOI: https://doi.org/10.1103/PhysRevB.71.035428.

10.

Hichri

Yosra, Veronique Cerezo, Minh Tan Do. 2017. „Effect of dry deposited

particles on the tire/road friction”. Wear

376-377: 1437-1449.

DOI: https://doi.org/10.1016/j.wear.2017.01.037.

11. Wilson Douglas James. 2006.

„An analysis of the seasonal and short-term variation of road pavement

skid resistance”. PhD thesis.

The University of Auckland.

12. Kulakowski B., D. Harwood, U. Kreßel. 1990. “Effect of water-film thickness on tire-pavement friction”. In: Surface

characteristics of roadways: international research and technologies. Edited by W. Meyer and J. Reicher. P. 50-60. ASTM International.

ISBN: 978-0-8031-5110-9.

13. Lambourn R.F., H.E. Viner. 2006. Friction tests on contaminated road surfaces. Transport Research Laboratory (TRL). Transport Research Laboratory.

ISBN: 1-84608-935-2.

14.

Way Li

Kai, Fanxing Meng, Wei Zhang. 2014. „Friction between footwear and floor

covered with solid particles under dry and wet conditions”. International Journal of Occupational Safety and Ergonomics 20(1): 43-53.

DOI: 10.1080/10803548.2014.11077027.

15.

Mills

R., R.S. Dwyer-Joyce, M. Loo-Morrey. 2009. „ The mechanisms of pedestrian

slip on flooring contaminated with solid particles”. Tribology International 42(3):

403-412. DOI: https://doi.org/10.1016/j.triboint.2008.07.013.

16.

Heshmat

Hooshang. 1993. „Wear reduction

systems for coal-fueled diesel engines II. Experimental results and

hydrodynamic model of powder lubrication”. Wear 16:

518-528. DOI: https://doi.org/10.1016/0043-1648(93)90537-V.

17. Yosra Hichri, Cerezo Véronique,

Do Minh-Tan. 2018. „Effect of fine particles on road skid

resistance”. In: 8th Symposium on

Pavement Surface Characteristics (SURF) 16: 518-528. 2-4 May 2018. Brisbane, Queensland,

Australia.

18. Davari Mohammad. 2019.

„Determining the appropriate asphalt pavement in areas with dust from the

point of view of surface friction”. Master’s

thesis. Iran: Yazd University.

19. ASTM E965-15:2019. Standard Test method for measuring pavement Macrotexture Depth using a volumetric Technique. West conshohocken: ASTM International.

20.

Elger

Donald F., Barbara A. Lebret, Clayton T. Crowe, John A. Roberson. 2020. Engineering fluid mechanics. Washington State Uninercity. ISBN: 978-1-119-72350-9.

Received 09.04.2021; accepted in revised form 22.06.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License