Article

citation information:

Fabiś, P., Flekiewicz, M. Optimalisation of the SI

engine timing advance fueled by LPG. Scientific

Journal of Silesian University of Technology. Series Transport. 2021, 111, 33-41. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2021.111.3.

Paweł FABIŚ[1], Marek FLEKIEWICZ[2]

OPTIMALISATION

OF THE SI ENGINE TIMING ADVANCE

FUELED BY LPG

Summary. This study is an attempt to determine the control

parameters of the control system for gaseous fuels currently used for driving

vehicles. It presents the selected dynamic parameters of the car obtained when

fueling the engine with petroleum-based LPG. This paper attempts to determine

the optimal timing advance of the gas-air mixture and the efficiency of its

processing in the drive system of the tested vehicle driven by a four-cylinder

engine with a 1.6 dm. More

so, this article includes an analysis of the influence of the optimised power

charts of the engine on the dynamics of the motion of a motor vehicle running

on gaseous fuel. To present changes in the dynamics of movement, indicators and

parameters determining changes in the dynamics of vehicle movement, such as

dynamic coefficient, acceleration and flexibility were used. Through this

analysis, it is possible to verify the optimised power and torque waveform and

determine whether the vehicle dynamics improved.

Keywords: LPG, power charts, timing advance

1. INTRODUCTION

The achievement of low emissions in exhaust gases from

SI engines currently determines the development trends

of motor vehicles. These include both the introduction of new technical and

technological solutions in fuel injection systems, improvement of the

combustion process, exhaust gas cleaning systems, and the use of alternative

fuels. The advantage of using alternative fuels is, among other things, the

fact that the combustion engine driving the vehicle does not require major

modifications, and the existing infrastructure ensures the smooth supply of

these fuels. In addition, the currently applicable dual-fuel alternative

gasoline or LPG or CNG systems are solutions that increase vehicle autonomy,

considering its beneficial environmental aspects, it also ensures the economics

of operation due to the advantageous price ratio compared to gasoline [9, 10].

Despite the critical assessments of environment benefits resulting from the use

of alternative gaseous fuels, which appear in some scientific studies, most

vehicle manufacturers include them in the adopted development strategies of the

product being manufactured [1, 2]. This is also because currently available

technologies enable the production of these fuels from biomass, thus, qualifies

them for renewable fuels. Current LPG and CNG systems ensure relatively fast

adaptation of the vehicle to fuel with these fuels, and the results of their

tests, carried out following the requirements of UN / ECE Regulation 115,

confirm the reduction of CO2 emissions and controlled exhaust

components compared to the emission obtained for gasoline.

The scope of tests carried out following the

requirements of Regulation 115 does not specify dynamic indicators of a motor

vehicle, and in most publications, it presents only the maximum power achieved

by the engine or on the wheels of a motor vehicle. Hence, in this article,

tests were carried out aimed at comparing the influence of the ignition advance

angle on selected indicators characterising the vehicle performance. The basis

for calculations were the external characteristics of the Opel Astra 1.6

engine, which was powered by LPG. The engine and the fuel dose control system

did not introduce any changes, modifications were introduced in the management

of the ignition advance angle. Obtained results of the calculations explain the

effect of changes in the ignition advance angle on changes in the dynamics of

the tested vehicle.

2. TEST OBJECT

CHARACTERISTICS

The SI engine of the Opel Astra 1.6 was used in the

tests. Its basic technical parameters together with the characteristics of the

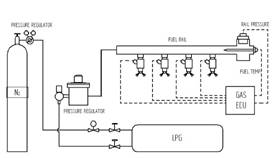

car are shown in Table 1. The engine was powered by LPG fuel, using independent

power supply systems, providing the engine with a mixture of liquefied gases

with a pressure not exceeding 0.5 MPa. The system provided a multi-point

injection of gaseous fuel, whereby the gas condensed after evaporation was

injected at a pressure of 10.0 kPa. The simplified block diagram of the system

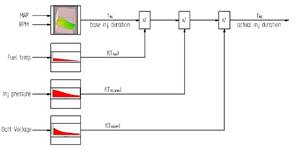

is shown in Figure 1. In contrast, Figure 2 explains how to control the dose of

gaseous fuel.

Based engine data characterised researched car shown in

Table 1.

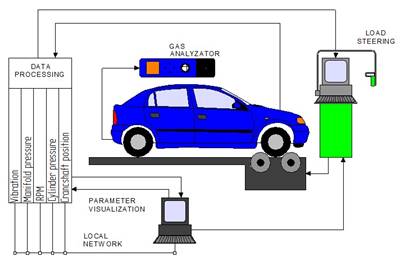

The performance of the car was determined by analysing

its dynamic characteristics, expressing the dependence of power developed on

the wheels from the speed of the car, which was obtained using a Bosch FLA 203

chassis dynamometer. A simplified diagram of the position is shown in Figure 3.

Changes in the ignition advance angle were conducted using a programmable

computer allowing for changing the settings of the data at each engine work point

or within a specified range. Further, the test stand was equipped with

transducers and sensors that ensure the identification of the engine's

operating status. The basic control and measurement systems ensuring continuous

recording of the engine operation state were, inter alia, devices enabling

measurement of:

• pressure in the engine cylinders,

• angle of rotation of the crankshaft with the

determination of the piston GMP,

• power developed on the wheels of the tested car,

• negative pressure prevailing in the intake

manifold,

• temperature of the intake air and exhaust gases.

|

|

|

|

Fig. 1. Scheme of operating system [9] |

Fig. 2. Scheme of engine control system [9] |

Tab. 1

Based parameters of the car engine

|

Number

of cylinders |

4 R |

|

Maximum

power and RPM |

55 kW /

5200 1/min |

|

Maximum

torque and RPM |

128 Nm /

2800 1/min |

|

Capacity |

1598 cm3 |

|

Diameter |

79.0 mm |

|

Stroke |

81.5 mm |

|

Compresion

ratio |

9.6 |

Fig. 3. Scheme of testing stand [9]

The pressure inside the cylinder was measured using a 6121 piezoelectric pressure sensor and KISTLER type 5011 charge amplifier. The position of the crankshaft and its rotational speed were determined using the KISTLER type 2613B crankshaft position marker. This transducer is an integral part of the gasoline fuel dose management system, injected into the intake manifold of the tested car's engine.

The mass flow of gaseous fuel flowing into the engine power system was measured using a precision tensometric weight. All measured parameters were recorded and visualised using the NI PCI-6143 data acquisition card and a proprietary program developed in the environment LabView 7.1.

3. RESULTS AN

DISCUSSION

3.1. Power and torque results

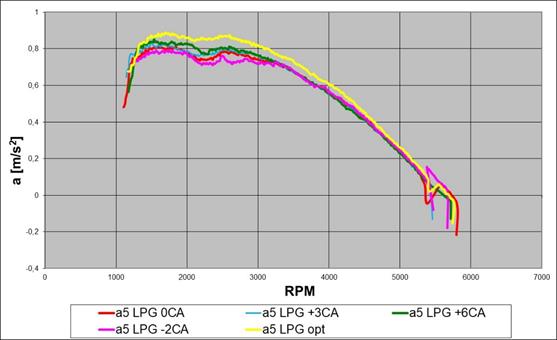

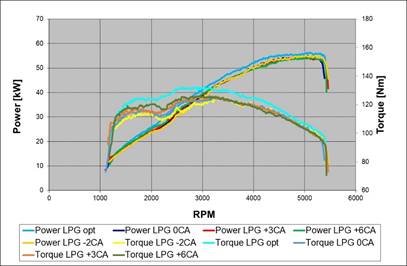

The results of power and torque measurements developed by the car engine, fueled by LPG at various ignition timing angles, are presented in Table 2, and the course of changes in power and torque depending on the engine speed is shown in Figure 4.

Tab. 2

Power and torque received during dynamometers test

|

L.p. |

Fuel and CA change |

Power [kW] |

nN [min-1] |

Torque [Nm] |

nM [min-1] |

|

1 |

LPG 0CA |

55,02 |

5051 |

125,19 |

3337 |

|

2 |

LPG +3CA |

54,55 |

4812 |

125,96 |

3288 |

|

3 |

LPG +6CA |

54,34 |

5190 |

126,08 |

2889 |

|

4 |

LPG -2CA |

55,07 |

5210 |

125,06 |

3367 |

|

5 |

LPG opt |

56,27 |

5091 |

132,55 |

2600 |

The obtained results indicate a clear change in the

engine power and torque depending on the ignition advance angle in the gas

mixture feeding the engine. By increasing the lead in the ignition angle, the

maximum power and torque are reduced. If the value of the ignition advance

angle is reduced, a clear increase in the maximum power value is observed. The

situation changes dramatically when the ignition advance angle is optimised and

values changing the torque and power curve in specific speed ranges are

introduced. In the 1000 - 2500 min-1 speed range, an angle of + 6st has been

entered, in the range of 2,500 - 4,500 min-1 an angle of + 3 degrees has been

introduced, while in the range above 4500 min-1 an angle of -2st has been

introduced. When using such an optimised ignition angle, a distinct change in

the external motor characteristics is obtained.

Fig. 4. Performance characteristics of

engine powered by LPG

with different crank angle set up

3.2. Method for fast determination of a

dynamic factor and vehicle acceleration

The dynamic properties of the car are compared using technical indicators expressing unit power, force or mass values. However, the dynamic indicator is usually used in the lowest and highest gears. It is the most universal indicator defining the car's engine properties, for example, climbing ability, ability to accelerate and overcome road resistance. This ratio is expressed as the following relationship:

|

|

(1) |

where:

Temax –

engine max torque, Nm,

io – final

drive ratio,

ig – gear

ratio,

Fa

– Air resistance force, N,

hm – mechanical efficiency of the transmission drive,

W – Total vehicle

weight, [N],

rd – dynamic

radius of the wheel, N.

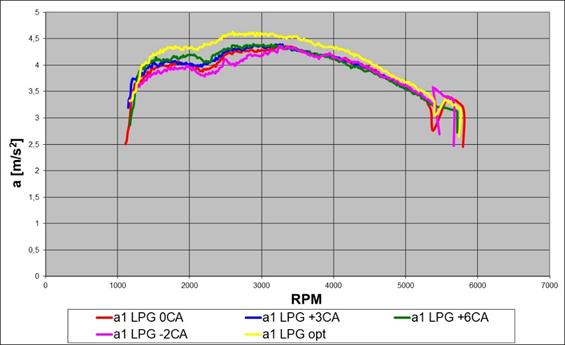

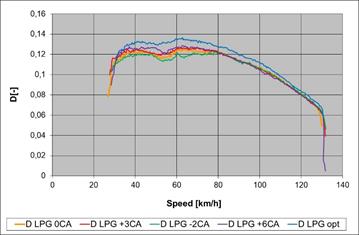

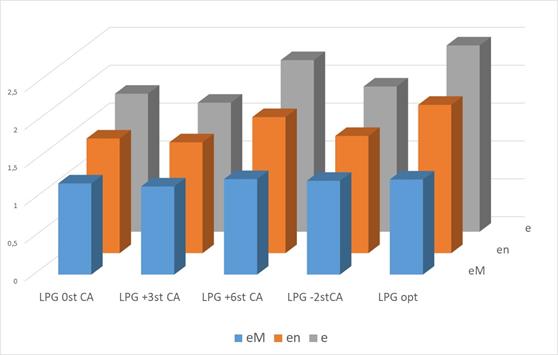

Usually, its value is determined in the highest gear. Figure 5 shows the dynamic coefficient waveforms for different values of the ignition advance angle and the mileage optimised.

Acceleration of the vehicle in a particular

gear (ai) can be calculated from the following expression:

|

|

(2) |

where:

g – acceleration of g-force,

Di – dynamic factor

(characteristic) in a particular gear,

f – rolling resistance

coefficient,

di – rotating masses influence coefficient.

Fig. 5. Dynamic

factor characteristics of engine powered by LPG

with various timing advance

The analysis of the

results from the above figure shows that LPG with optimalised crank angle gave

higher car dynamics than the rest set angles. The difference between the fuels

is clearly visible in the whole range of car speed. It is caused by the

different crank angle set up for different rpm range as shown above.

Figure 6 shows the engine flexibility as a supplement describing the change in the car dynamics.

Described engine

flexibility at some part of range is the same value as a dynamic factor as seen

in Figure 7. The exception is the higher value of flexibility optimalisation

LPG fuel with corrected spark timing.

4.

CONCLUSIONS

Researches on the

use of vehicle feed LPG fuel allowed describing how the kind of engine

parameter includes car dynamic. Due to the description of done dyno test which

given power and torque engine allows calculation of dynamic factor,

accelerations and flexibility. Certified that the crank angle timing influences

the maximum power and torque value. An appropriately set crank angle timing is

given the torque and power increase. Set one timing angle for whole rpm range

improves the torque and power value only for the chosen range. This is the

reason for the optimalisation of the crank angle timing for the whole rpm range

as it improves its given power and torque at all range. Proposed value of

timing angle optimalising and improve the course of power and torque. For the

proposed timing angle value (+6°CA, +3°CA and -2°CA), power

increased over 1 kW and torque over 7 Nm.

|

a) |

|

|

|

b) |

|

|

|

Fig. 6. Acceleration characteristics of engine powered by LPG with various timing advance, a) lowest gear, b) highest gear |

Fig. 7. Flexibility

of engine powered by LPG fuels for different crank angle set up

References

1.

Merkisz J., S. Radzimirski. 2006.

„Does the propane-buthane gas is an

ecological fuel?” Internal

Combustion Engines 2(125).

2.

Toyota's Strategy for Environmental Technologies.

Available at:

http://www.toyota-global.com/innovation/environmental_technology/strategy_environmental_tech.html.

3.

PZPM Raport. 2013.

4.

Van Mierlo J., G. Vereecken, G. Maggetto, V. Farrel, S. Meyer,

W. Hecq. 2003. „Comparizon of the

Environmental Damage Caused by Vehicles with Different Alternative Fuels and

Drivetrains in a Brusells Context”. J.

Automotive Eng. Proc. IMechE Part D

217(D7): 583-594.

5.

Campbell M., Ł.P. Wyszyński, R. Stone. 2004. „Combustion of LPG

in a Spark-Ignition Engine”. SAE

Paper 2004-01-0974.

6.

Fabiś P. 2005 „Measuring the indicated pressure and engine

block vibration – conception of the test stand”. XXXII National Symphosium of the Machine Diagnostic. Węgierska

Górka, Poland.

7.

Heywood J.B. 1998. Internal

combustion engines fundamentals. McGraw-Hill. New York.

8.

Rogers D.R. 2010. Engine

Combustion: Pressure Measurement and Analysis. SAE International.

9.

Usman M., N. Hayat. 2020. „Lubrication, emission and performance analyses of LPG

and petrol in a motorbike engine: a comparative study”. Journal of the Chinese Institute of

Engineers 43(1): 47-57. Available at:

https://doi.org/10.1080/02533839.2019.1676656.

10.

Simsek S., S. Uslu. 2020. „Investigation of the impacts of gasoline,

biogas and LPG fuels on engine performance and exhaust emissions in different

throttle positions on SI engine”. Fuel 279: 118528. DOI:

https://doi.org/10.1016/j.fuel.2020.118528.

Received 12.02.2021; accepted in revised form 27.04.2021

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License