Article

citation information:

Drbal, M. A method of rotary engine

performance prediction. Scientific

Journal of Silesian University of Technology. Series Transport. 2020, 108, 37-43. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2020.108.4.

Milan DRBAL[1]

A

METHOD OF ROTARY ENGINE PERFORMANCE PREDICTION

Summary. The rotary engine mainly developed for the

automotive industry by the NSU corporation is currently used in unmanned

aircraft, transportable generators and small watercraft. In the early stage of

the engine development, the simulation of the performance characteristics is

advisable. The 3D CFD engine simulation is highly expensive in terms of CPU

time demand and requires a high level of optimisation to provide adequate data.

This method can be used later in the development and fine engine tuning. For

the design of the prototype 1D, simulation is being used as a tool to compare

various designs of the engine. While the current commercially available

software (GT-suite, Ricardo Wave, etc.) is being improved marginally, the

functionality of the software is being tested on the piston reciprocating

engines. This paper explores the possibility of the algorithms of such a

software to be used on the rotary engine thermodynamic simulation and provides

an approach to design a simulation model that can be solved by the software to

predict the performance characteristics of the engine prototype.

Keywords: internal combustion engine, rotary engine, 1D

simulation

1. INTRODUCTION

The commercially available performance

prediction software (GT-power, Ricardo Wave, etc.) for combustion engines

currently does not include support for rotary engines. The main reason is the

significantly lower market demand for these engines. For the time-efficient

prediction of the performance parameters during the early stage of the

development of the rotary power unit, it is advisable to use a one –

dimensional software. Unfortunately, the direct use of the available software

for the piston engines is not possible because of the following differences

between the two engine designs [3, 16-18, 21, 23, 24, 26]:

- the ratio of the main shaft rotation to the

4-stroke cycles of the rotary engine is equal to 3. Single-cylinder 4-stroke

piston engine crankshaft rotates twice for the same quantity of cycles,

- the difference of the surface to displacement

ratio during the main-shaft rotation,

- the difference in the heat-transfer proprieties

coming from the differences in the geometric shape of the combustion chamber,

- the length of the combustion chamber increases the

time of the combustion process, which reduces the overall efficiency of the

combustion,

- the movement of the working chamber across the

whole loop of the main housing influences the difference in the temperature

distribution of the engine. The speed of this process also influences the speed

of the flame propagation through the working chamber as the leading apex seal

of the rotor is constantly moving forward from the flame front.

The main objective of this paper is the creation

of the virtual piston engine (VPE) with modified parameters that correspond to

the designed rotary engine. The VPE will then be used as a model for the 1-D

solver to provide the required data for the development process.

Responsibility for the use of photos and

drawings in the sent materials of articles rests on the authors.

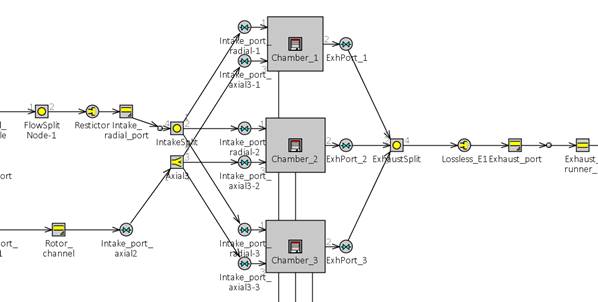

2. COMPUTATIONAL MODEL

The initial condition in the

simulation model setup must be the equity of the volume of the operating

chambers in relation to the crankshaft rotation.

As the input, the piston position of

the virtual piston engine (VPE) in relation to the crank-shaft angle α is

used in the algorithm, the equation used for the virtual piston position [14]:

![]() (1)

(1)

where e

is the eccentricity of the rotary mechanism, λ is the trochoid constant, α is the relative angle of the rotor, S4 is the area between the outer shell of the trochoid

and the line between 2 apexes of the rotor, hp

is the rotor width and Vp

is the rotor hollow volume.

The bore of the VPE is taken as the diameter of

the circle with equal area to the area of the rotor exposed to the working

chamber. The head area of the cylinder of the piston reciprocating engine

remains constant during the engine operation, however, in the rotary engine

from its principle the area changes with the main shaft rotation. This

difference is not accounted for in the algorithms for the 1D simulation solver.

The virtual area of the head equivalent surfaces is therefore calculated as the

weighted average with the heat flux to the head area as the weight of the

calculation. The rotary engine of the Wankel type works with four-stroke cycle

and each rotor and housing pair creates 3 working chambers. For these reasons,

using the four-stroke template with 3 cylinders configuration is advisable. To

maintain the equity of the volumetric flow through the VPE and the rotary

engine, the ratio of the main shaft rotation to the rotation of the crankshaft

of the VPE is 3/2. The cylinders are interconnected with the piping of the negotiable

length simulating the overflow of the exhaust and the intake during the port

openings to the adjacent chambers. Both intake and exhaust port openings were

simulated with a kinematic simulation to determine the active areas of the

ports in relation to the main shaft rotation. The calibration of the flow

coefficient of the ports was done using the CFD approach (Fig. 2), then further

calibrated in the GT-Power software via volumetric flow measured on the test

engine.

Fig. 1. Base structure of the mathematical

model

3. SIMULATION RESULTS

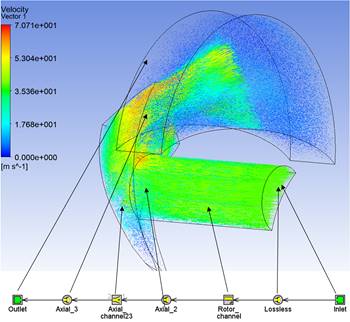

For

the first iteration of the port flow coefficients calculation, the 3D CFD

method was used [13]. As the experimental method of using the blow through

mass-flow measuring station cannot be executed in the early stages of the

development due to the lack of the physical engine model, using the commercial

computational software is the only option to determine these parameters. The

discharge coefficients of the intake and exhaust system were computed at the

major points of the system. Intake and exhaust port opening and closing

discharge coefficients were approximated by the linear function as this

approach reduces the time needed for the 3D CFD method and can be used without

large error as presented in the [2]. Due to the complexity of the axial intake

system on the simulated engine, two simulations were carried out [4, 5]. The

results of the simulations were then used to calibrate the 1D model of the

virtual piston engine.

Fig. 2. Axial intake port 3D calibration

Using

the previous input data calibrations from the known engine, the simulation was

run to evaluate the concept of the virtual piston engine creation. For the

engine performance, the average difference of the simulated and measured values

was 3.08% (Fig. 3). Torque and power are the overall engine characteristics,

which determine the quality of the method used in the simulation, however, for

the previously mentioned discharge coefficient calibration validation of the 1D

model, engine air mass flow is used.

Fig. 3. Engine prediction

correlation with measured data

4. CONCLUSION

As the commercially available software for

thermodynamic simulation of the rotary engine is not available due to the

comparably low market demand to the reciprocating-piston engine type, the

available software input can be modified to provide accurate simulation

results. The method of creating the virtual piston engine is shown using the

calculated bore, stroke and piston position data to provide the equivalent

surface area and volume of the working chamber. The calculation method using

the 3D CFD software was applied for the complicated axial intake of the engine.

Using the outcome of the 3D simulation, the 1D simulation model was calibrated

to provide the comparable mass air flow results. The heat transfer coefficients

were calculated using the forced convection over the flat plane analogy. These

results are then used as weight for the average calculation of the head surface

area, which remains constant in the reciprocating-piston engine but changes

with the angle of the main shaft in the rotary engine. For future work, testing

is required to measure the in-cylinder pressure data and temperature and

pressure data from the engine intake and exhaust system as these are to be used

for the model calibration. Additionally, further development of the rotary

engine needs to solve NVH problems using the methods described in [10, 11, 19, 20,

22] and further modify using prototyping methods [8, 9], the control units for

its specific applications. Using this advanced simulation and experimental

methods, the new rotary engine unit parameters can be designed, optimised and

performance predicted. Modern production technologies [1, 6, 7, 12, 15, 25]

will be used to produce optimised rotary engine components.

Acknowledgement

The authors gratefully

acknowledge funding from the Specific research on BUT FSI-S-20-6267.

References

1.

Balevicius

Gytautas, Vytautas Ostaševičius, Vytautas Jurėnas, Jolanta

Baskutienė, Robertas Zakrasas. 2016. „Investigation of vibration

assisted drilling prospects for improving machining characteristics of hard to

machine materials at high and low frequency ranges”. Mechanika 2: 125-131.

2.

Bartrand Timothy

A., Edward A. Willis. 1990. „Performance of a supercharged

direct-injection stratified-charge rotary combustion engine”. Symposium General Aviation Systems:

1-24. Cosponsored by the AIAA and FAA

National Aeronautics and Space Administration, Cleveland, USA. 11-12 April

1990, Ocean City, USA.

3.

Brestovič

Tomáš, Natalia Jasminská, Mária

Čarnogurská, Michal Puškár, Michal, Kelemen Milan

Fiľo. 2014. „Measuring of thermal characteristics for Peltier

thermopile using calorimetric method”. Measurement 53: 40-48. DOI: https://doi.org/10.1016/j.measurement.2014.03.021.

4.

Handschuh Robert

F., Owen Karl A. 2010. Analysis of apex

seal friction power loss in rotary engines. Cleveland: Glenn Research

Center.

5.

Irion C.E., R.E.

Mount. 1992. Stratified charge rotary

engine critical technology enablement. Volume I. Wood-Ridge: Lewis Research

Center.

6.

Karpavičius

Paulius, Vytautas Ostaševičius, Vytautas Jūrėnas, Jolantas

Baskutienė. 2017. „Self-powered wireless sensor system application

for cutting process control”. Mechanika

23(3): 456-461.

7.

Košinár

Matúš, Ivan Kuric. 2011. „Monitoring possibilities of CNC

machin tools accuracy”. 1st

International Conference on Quality and Innovation in Engineering and

Management (QIEM): 115-118. Cluj

Napoca. 17-19 March 2011. ISBN: 978-973-662-614-2.

8.

Kučera Pavel,

Václav Píštěk. 2019. „Prototyping a system for

truck differential lock control”. Sensors

19(16): 1-18. ISSN: 1424-8220. DOI: 10.3390/s19163619.

9.

Kučera Pavel,

Václav Píštěk. 2017. „Testing of the mechatronic

robotic system of the differential lock control on a truck”. International Journal of Advanced Robotic Systems

14(5): 1-7. ISSN: 1729-8814. DOI: 10.1177/1729881417736897.

10. Kučera Pavel, Václav

Píštěk. 2017. „Truck vibrations caused by rotating shaft

deflection”. Journal of

Vibroengineering 19(7): 5361-5373. ISSN: 1392-8716. DOI:

10.21595/jve.2017.18028.

11. Kučera Pavel, Václav

Píštěk, Aleš Prokop, Kamil Řehák. 2018.

„Measurement of the powertrain torque”. 24th International conference Engineering Mechanics: 449-452.

Institute of Theoretical and Applied Mechanics of the Czech Academy of

Sciences, Prague, Czech Republic. 14-17 May 2018, Svratka, Czech Republic.

ISBN: 978-80-86246-88-8.

12. Kuric Ivan. 2011 „New methods and trends in

product development and planning”. 1st

International Conference on Quality and Innovation in Engineering and

Management (QIEM): 453-456. Cluj Napoca, 17-19 March, ISBN:

978-973-662-614-2.

13. Neumann Stefan, Roman Varbanets, Olena Kyrylash,

Oleksiy Valerievich Yeryganov, Vladyslav Olegovich Maulevych. 2019.

“Marine diesels working cycle monitoring on the base of IMES GmbH

pressure sensors data”. Diagnostyka

20(2): 19-26. DOI: https://doi.org/10.29354/diag/104516.

14. Norbye Jan P. 1971. The Wankel engine: design, development, applications. Denver:

Chilton Book Co. ISBN: 0801955912.

15. Ostasevicius V., V. Jurenas, A. Juskevicius. 2014.

„Modified tool structures for effective cutting”. Mechanika 2: 171-176.

16. Pacana A., K. Czerwińska, L. Bednarova. 2019.

“Comprehensive improvement of the surface quality of the diesel engine

piston”. Metalurgija 58(3-4): 329-332. ISSN: 0543-5846.

17. Pacana A., K. Czerwińska, L. Bednarova. 2018.

“Discrepancies analysis of casts of diesel engine piston”. Metalurgija 57(4): 324-326. ISSN: 0543-5846.

18. Piątkowski J. 2015. “AlSi17Cu5Mg alloy as

future material for castings of pistons for internal combustion engines”.

Metalurgija 54(3): 511-514. ISSN: 0543-5846.

19. Píštěk Václav, Lubomír

Klimeš, Tomáš Mauder, Pavel Kučera. „Optimal design

of structure in rheological models: an automotive application to dampers with

high viscosity silicone fluids”. Journal

of Vibroengineering 19(6): 4459-4470. ISSN: 1392-8716. DOI:

10.21595/jve.2017.18348.

20. Prokop Aleš, Barbora Kopečková, Kamil

Řehák. 2017. „Gear drive system simulation of input

parameters effect on rattle”. 14th

Conference Acoustics and Vibration of Mechanical Structures (AVMS):

381-388. University Politehnica Timişoara, Timişoara, Romania. 25-26

May 2017, Timisoara, Romania. ISBN: 978-3-319-69822-9.

21. Puškár Michal, Tomáš

Brestovič, Natalia Jasminská. 2015. „Numerical simulation and

experimental analysis of acoustic wave influences on brake mean effective

pressure in thrust-ejector inlet pipe of combustion engine”. International Journal of Vehicle Design 67(1):

63. DOI: https://doi.org/ 10.1504/ijvd.2015.066479.

22. Řehák Kamil, Pavel Kučera, Aleš

Prokop. 2019. „Application of virtual prototype to heavy-duty gearbox

housing evaluation”. International

Scientific Conference Transbaltica XI: Transportation Science and Technology:

361-368. Vilnius Gediminas Technical University, Vilnius, Lithuania. 2-3 May

2019, Vilnius, Lithuania. ISBN: 978-3-030-38665-8.

23. Sinay Juraj, Michal Puškár, Melichar

Kopas. 2018. „Reduction of the NOx emissions in vehicle diesel engine in

order to fulfill future rules concerning emissions released into air”. Science of the Total Environment 624:

1421-1428. DOI: https://doi.org/10.1016/j.scitotenv.2017.12.266.

24. Tartakovsky Leonid, Vladimir Baibikov, Marcel Gutman,

Mark Veinblat M. 2012. ,,Simulation of wankel engine performance using

commercial software for piston engines”. SAE Technical Paper 32 0098: 1-13. ISSN: 0148-7191. DOI:

10.4271/2012-32-0098.

25. Tlach Vladimír, Miroslav Císar, Ivan

Kuric, Ivan Zajačko. 2017. „Determination of the industrial robot

positioning performance”. MATEC Web

of Conferences 137(01004). DOI: https://doi.org/

10.1051/matecconf/201713701004.

26. Todić V, J. Tepić, M. Milošević,

D. Lukić, M. Hadžistević. 2012. “Design of casting blanks

in CAPP system for parts of piston-cylinder assembly of internal combustion

engines”. Metalurgija 51(1): 75-78. ISSN: 0543-5846.

Received 07.04.2020; accepted in revised form 20.06.2020

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License