Article

citation information:

Marinov, M., Petrov, Z. A static calibration of MEMS 3-axis

accelerometer using a genetic algorithm. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 105, 157-168. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.105.13.

Marin MARINOV[1],

Zhivo PETROV[2]

A STATIC CALIBRATION OF

MEMS 3-AXIS ACCELEROMETER USING A GENETIC ALGORITHM

Summary. In this paper, a procedure for MEMS accelerometer

static calibration using a genetic algorithm, considering non-orthogonality was

presented. The results of simulations and real accelerometer calibration are

obtained showing high accuracy of parameters estimation.

Keywords: MEMS accelerometers,

calibration, bias, genetic algorithm

1. INTRODUCTION

Various microelectromechanical

systems (MEMS) are used in different devices. Some of the most used are MEMS

accelerometers. There are many areas of MEMS accelerometers application, such

as location of objects, tracking of human movement, control of mirrors in

cameras, etc. [2,3,5,11]. They are small, lightweight

and provide digital outputs, but possess relatively large errors. Different

ways of accelerometer calibration are used to improve accuracy.

The most important step for

accuracy improvement is the static calibration of the accelerometer. It must be

done separately for each particular accelerometer. There are two basic types of

models of accelerometer static errors. One includes only biases and scale

factors, which means 6 parameters [4,7,8]. The other

models include terms for non-orthogonality between accelerometer axes [9,10]. It is more complex to estimate nine or more

parameters, but in this way, a higher accuracy is achieved. Various methods for

estimation are used. Some of them require special equipment for the perfect

orientation of accelerometers [1,6,12,14], but those

that do not require such are more useful [4,7-9].

Usually, algorithms of static

calibration minimise the fitness function. Some of

them used linearisation of the function [1,4,7], but they are sensitive to the presence of random. A

lot of studies of algorithms without linearisation

have been published [8,9,13,14].

Using a genetic algorithm for

static accelerometer calibration is presented in this paper. A mathematical

model of measurement is used to define the fitness function. The results of

simulations and of calibration of real MEMS accelerometer are shown.

2. CALIBRATION ALGORITHM

Models of accelerometer

measurement with nine parameters are shown in [9,10].

A slightly modified model is used in this paper:

![]() (1)

(1)

where:

![]() is the acceleration vector in the accelerometer orthogonal

frame (AOF)

is the acceleration vector in the accelerometer orthogonal

frame (AOF)

![]() is the measured acceleration vector in the accelerometer

body frame (ABF)

is the measured acceleration vector in the accelerometer

body frame (ABF)

b is the vector of biases

n is the vector of the measurement noise, which is vector of white

Gaussian noises;

is the transition matrix from ABF to AOF

is the transition matrix from ABF to AOF

is the matrix of scale factors

is the matrix of scale factors

Averaging of

measurements in time is done to exclude random errors:

![]() (2)

(2)

where: ![]() is the averaged

acceleration vector in AOF;

is the averaged

acceleration vector in AOF; ![]() is the averaged

measured acceleration vector in ABF.

is the averaged

measured acceleration vector in ABF.

When the accelerometer is in a stationary position,

the vector ![]() is equal to the

gravitational

acceleration vector g and (2)

becomes:

is equal to the

gravitational

acceleration vector g and (2)

becomes:

![]() (3)

(3)

Modern digital MEMS

accelerometers data are not read in m/s2,

but in units of g. Consequently, the

norm of the gravitational acceleration vector is 1 and consequently the

equation (3) becomes:

![]() (4)

(4)

The averaged measurements in

significantly different positions of the accelerometer are recorded. Using (3)

and data from these measurements, the fitness function is defined as:

![]() (5)

(5)

where: ![]() is the vector of

the evaluated parameters;

is the vector of

the evaluated parameters; ![]() are the vectors

of averaged measurements in different positions; N is the number of positions.

are the vectors

of averaged measurements in different positions; N is the number of positions.

Therefore, a genetic algorithm for minimising of the fitness function

(5) is used. The basic

parameters of the genetic algorithm are:

- number of individuals in the current generation that survive to

the next generation called elite children – 2,

- fraction of the population at the next generation, excluding the

elite children from parents of the previous generation - 0.8,

- fraction of the smaller of the two subpopulations of individuals

that migrate from one to another subpopulation is 0.2,

- the algorithm stops if the average relative change in the best

fitness function value over 50 generations is less than or equal to 10-10

or the number of generations reaches 150,

- the population size (number of

individuals in each generation) is 200.

The vector of the evaluated

parameters is the vector from the last generation for which the fitness

function is minimal. The outputs of the genetic algorithm are random variables,

so the mean values from applying the algorithm 20 times with the same input

data are taken as estimates. The algorithm is applied iteratively 3 times.

Before the second and third iterations, new lower and upper bounds of

parameters are calculated:

(6)

(6)

where: ![]() is the mean

vector from 20 times application of the genetic algorithm on the first

iteration;

is the mean

vector from 20 times application of the genetic algorithm on the first

iteration; ![]() is the vector of

standard deviations of estimated parameters of 20 times application of the

genetic algorithm on the first iteration;

is the vector of

standard deviations of estimated parameters of 20 times application of the

genetic algorithm on the first iteration; ![]() is the mean

vector of 20 times application of the genetic algorithm on the second

iteration;

is the mean

vector of 20 times application of the genetic algorithm on the second

iteration; ![]() is the vector of

standard deviations of estimated parameters of 20 times application of the

genetic algorithm on the second iteration.

is the vector of

standard deviations of estimated parameters of 20 times application of the

genetic algorithm on the second iteration.

The estimated parameters are

used in equation (2) to find estimated acceleration.

3. RESULTS AND DISCUSSION

The first step of the

simulation is to generate a set of accelerometer positions. The second step is

to add errors in order to create a simulation of measurements. The third step

is to apply the iterative procedure described above.

Тhe simulation of а set of accelerometer positions

is done by Euler rotations about each axis as it is described in [3] and the

total number of the positions of the accelerometer is the sum of the number of

rotations about each axis(Nx, Ny, Nz). The second and third steps of the simulation

are the same as in [8].

One hundred simulations for

each number of accelerometer positions are done to examine estimation errors.

Different random rotations, biases and scale factors are generated in each

simulation. The vector of estimation errors

![]() is obtained for

each simulation:

is obtained for

each simulation:

![]() (7)

(7)

where ![]() is the vector of

true parameters.

is the vector of

true parameters.

The errors of overall bias are also calculated:

![]() (8)

(8)

To evaluate the accuracy of

estimation, the means and standard deviations (STD) of errors are obtained. The

results for non-orthogonality terms when the numbers of rotation about axes are![]() ,

, ![]() and

and ![]() are shown in Fig.

1. The results show that the biggest means and standard deviations of errors

are after the first iteration. There are small differences between standard

deviations of errors for second and third iterations. It is obvious that the

means and standard deviations of Δαyz are much bigger than those of other

non-orthogonality terms, because of the absence of rotation about z-axis in

different accelerometer positions.

are shown in Fig.

1. The results show that the biggest means and standard deviations of errors

are after the first iteration. There are small differences between standard

deviations of errors for second and third iterations. It is obvious that the

means and standard deviations of Δαyz are much bigger than those of other

non-orthogonality terms, because of the absence of rotation about z-axis in

different accelerometer positions.

Fig. 1. Means and STD of

non-orthogonality terms estimation errors for Nx=12, Ny=12, Nz=0

The results for scale factors when the

numbers of rotation about axes are![]() ,

, ![]() and

and ![]() are shown in Fig.

2.

are shown in Fig.

2.

Fig. 2. Means and STD of

scale factors estimation errors for Nx=12, Ny=12, Nz=0

Figure 2 shows that the means

and standard deviations are smaller after the third iteration, but there is no

significant difference between the second and the third iterations. The means

of errors are below 10-5 for the second and the third iterations.

The values of the standard deviations are below 2.5×10-5 for

the same two iterations.

The results for biases when the

numbers of rotation about axes are![]() ,

, ![]() and

and ![]() are shown in Fig.

3. The results show that the estimation errors are much smaller for second and

third iterations. The means of bias estimation errors are less than 10-5g for

the second and third iterations while the standard deviations are below

2×10-5g.

are shown in Fig.

3. The results show that the estimation errors are much smaller for second and

third iterations. The means of bias estimation errors are less than 10-5g for

the second and third iterations while the standard deviations are below

2×10-5g.

The results for overall bias

estimation errors when the numbers of rotation about axes are![]() ,

, ![]() and

and ![]() are shown in Fig.

4. The means of errors are less than 3.5×10-5g for the second and third

iterations, and the standard deviations are below 1.6×10-5g.

are shown in Fig.

4. The means of errors are less than 3.5×10-5g for the second and third

iterations, and the standard deviations are below 1.6×10-5g.

The results for regarded

accelerometer positions show that the estimations of parameters by the proposed

genetic algorithm are good, but there are discrepancies in the estimates of

non-orthogonality terms.

Fig. 3. Means and

STD of estimation errors of biases for Nx=12, Ny=12, Nz=0

Fig. 4. Means and STD of overall bias

estimation errors for Nx=12,

Ny=12, Nz=0

The results when the numbers of rotation

about axes are Nx=8,

Ny=6, and Nz=4 are shown in Fig. 5 to 8.

Fig. 5. Means and STD of non-orthogonality

terms estimation errors for Nx=8, Ny=6, Nz=4

Fig. 6. Means and STD of scale factors

estimation errors for Nx=8,

Ny=6, Nz=4

Fig. 7. Means and STD of estimation errors

of biases for Nx=8,

Ny=6, Nz=4

Fig. 8. Means and STD of overall bias

estimation errors for Nx=8,

Ny=6, Nz=4

Obtained results showed that

the accuracy of parameters estimation is slightly higher compared to the

previous case. In this case, there are not such big differences between the

means and standard deviations of estimation errors of non-orthogonal terms.

The results when the numbers of

rotation about axes are Nx=8,

Ny=8, and Nz=8 are shown in Fig. 9 to 12.

Fig. 9. Means and STD of non-orthogonality

terms estimation errors for Nx=8, Ny=8, Nz=8

The obtained results show that

the standard deviations of estimation errors are slightly smaller than the

previous cases. The improvement is small enough to conclude that there is no

need to increase the number of accelerometer positions. The standard deviations

of biases estimation errors are practically less than the standard deviation of

quantisation error for 14-bit digital MEMS

accelerometer with a measurement range of ±2 g. The results prove that

there is no need to apply more than two iteration of genetic algorithm.

Fig. 10. Means and STD of scale factors

estimation errors for Nx=8,

Ny=8, Nz=8

Fig. 11. Means and STD of estimation

errors of biases for Nx=8,

Ny=8, Nz=8

Fig. 12. Means and STD of overall bias

estimation errors for Nx=8,

Ny=8, Nz=8

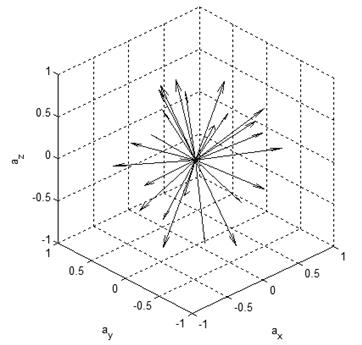

The proposed algorithm for

static calibration is applied to real 3-axis accelerometer in one MPU 6050 device. The MPU 6050 was

put on the head of a camera tripod. The head of the tripod was rotated by hand

in 25 different positions. In each position, output data was collected for a

period of 20 s. The data rate was 50 Hz and the measurement range was set to

±2 g. The recorded acceleration in each position was averaged in time to

obtain a set of 25 measured gravitational acceleration vectors. The measured

vectors in accelerometer body frame are shown in Fig. 13.

Fig. 13. Measured gravitational

acceleration vectors in ABF

The proposed algorithm is used

to evaluate the parameters of accelerometer parameters. The values of estimated

parameters are shown in Table 1.

Table. 1

Estimated

parameters by the proposed algorithm

|

αyz |

αzy |

αzx |

Sx |

Sy |

Sz |

bx [mg] |

by [mg] |

bz [mg] |

|

3.58×10-4 |

-7.29×10-3 |

4.62×10-4 |

1.0006 |

1.0030 |

0.9834 |

27.6253 |

-5.7079 |

-78.2870 |

In the datasheet of MPU 6050, the following values for the initial tolerance of

biases are given: bx=by=±50g and bz=±80g. As seen in Table 1, the obtained estimated values are

within these ranges. The differences between estimated biases on each axis are

significant.

The same set of data is used to obtain six

calibration parameters by the algorithm proposed in [8]. The estimated

parameters are shown in Table 2.

Table 2

Estimated parameters by the algorithm proposed in [8]

|

Sx |

Sy |

Sz |

bx [mg] |

by [mg] |

bz [mg] |

|

1.0008 |

1.0032 |

0.9835 |

28.1414 |

-5.4880 |

-77.2980 |

As could be seen from the above

tables, the estimated values of biases and scale factors by the two algorithms

are slightly different. To evaluate the accuracy of calibration, the following

calculations are made.

1. The calibrated measured

accelerations on each axis are calculated for all positions using the

parameters from the tables.

2. Double digital integration is

applied to calibrate accelerations in order to obtain the equivalent path on

each axis at each time moment [six(t), siy(t)

and siz(t)].

3. The errors in the overall

equivalent path for each position are calculated using the following formula ![]() .

.

4. Averaging over each position is

done at each time moment and the mean and standard deviation (ss) of errors in are obtained.

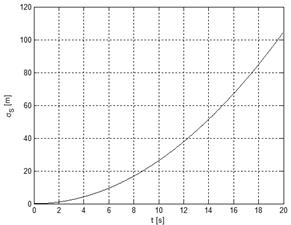

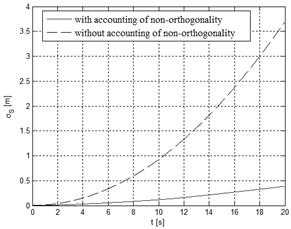

The calculated standard

deviation of errors of the overall equivalent path without calibration as a

function of time is shown in Fig. 14a. While the

calculated standard deviation of errors of the overall equivalent path with

calibration as a function of time is shown in Fig. 14b.

a) b)

Fig. 14. Standard deviation of errors of

the overall equivalent path.

The results show that the

standard deviation of errors of equivalent path without calibration at the end

of the period of 20 s is over 100 m. The standard deviation of errors in the

case of calibration with six parameters is less than 4 m and in the case of

calibration with nine parameters is less than 0.4 m. In this way, the accuracy

of path calculation, using the proposed algorithm of calibration, is more than

250 times better in comparison to the calculation without any calibration. The

improvement in accuracy of the proposed algorithm in comparison to the

algorithm with six parameters is about 10 times.

4. CONCLUSIONS

A procedure for MEMS

accelerometer static calibration, using a genetic algorithm, is proposed in

this paper. A fitness function for the genetic algorithm was defined. The

convergence of the estimates to the true values of parameters is very good.

Results from the simulations

and real accelerometer calibration showed that the proposed procedure provides

very good estimations of accelerometer parameters. The detailed studies showed

that two iterations are enough and that it is unnecessary to use more than 25

different positions of the accelerometer. Results of real accelerometer

calibration indicated much better accuracy when nine instead six parameters

were used.

References

1.

Bin Fang, Wusheng Chou, Li Ding. 2014. „An

Optimal Calibration Method for a MEMS Inertial Measurement Unit”. International Journal of Advanced Robotic

Systems 11(14): 1-14. DOI:

https://doi.org/10.5772/57516.

2.

Brunner

Thomas, Sebastien Changey, Jean-Philippe Lauffenburger, Michel Basset. 2015. “Multiple MEMS-IMU localization: Architecture comparison and performance

assessment”. In 22nd Saint

Petersburg International Conference on Integrated Navigation Systems, ICINS – Proceedings: 123-126.

State Research Center of the Russian Federation, Saint Petersburg, Russian

Federation. ISBN 9785919950233.

3.

Cai G., B.M. Chen, T.H. Lee. 2011. Unmanned

Rotorcraft Systems: Springer. ISBN 978-0-85729-634-4.

4.

Camps

F., S. Harasse. 2009. “Numerical calibration

for 3-axis accelerometers and magnetometers”.

In IEEE International Conference on

Electro/Information Technology. University of Windsor, Ontario, Canada. DOI: 10.1109/EIT.2009.5189614.

5.

Grankin Maxim, Elizaveta Khavkina,

Alexander Ometov. 2012. “Research of MEMS

Accelerometers Features in Mobile Phone”. In Proceeding of the 12th conference of FRUCT

association: 31-36. Finnish-Russian University Cooperation in

Telecommunication, Oulu, Finland. ISSN 2305-7254.ISBN 978-5-8088-0606-1.

6.

Prasant Kumar Mahapatra, Spardha, Inderdeep Kaur Aulakh, Amod Kumar, Swapna Devi. 2013. “Particle swarm optimization (PSO) based tool position error optimization”, International Journal of Computer

Applications 72(23): 25-32. ISSN 0975-8887.

7.

Marinov Marin, Zhivo Petrov. 2014. “An approach for static calibration of

accelerometer MMA8451Q”. In International conference AFASES:

189-192. “Henri Coanda” Air Force

Academy, Brasov, Romania. ISSN 2247-3173.

8.

Petrov

Zhivo, Liliana Miron. 2019.

“Opportunities of a genetic algorithm for static calibration of MEMS

accelerometers”. In International

annual scientific conference of Aviation Faculty: 346-353. Aviation

Faculty, National Military University, Dolna Mitroloia, Bulgaria, ISBN 978-954-713-123-1.

9.

Sinha Vikas, Maurya Avinash.

2017. “Calibration of Inertial Sensor by Using Particle Swarm Optimization

and Human Opinion Dynamics Algorithm”. In International Journal of Instrumentation and Control Systems 7(1):

1-13. DOI: 10.5121/ijics.2017.7101.

10. Tedaldi David, Alberto Pretto,

Emanuele Menegatti. 2014. “A robust and easy to

implement method for IMU calibration without external

equipments”. In Proceedings of IEEE

international conference on robotics and automation: 3042-3049. Hong

Kong, China. DOI: 10.1109/ICRA.2014.6907297. ISBN:

978-1-4799-3685-4. ISSN: 1050-4729.

11. Tian Jing, Wenshu

Yang, Zhenming Peng, Tao Tang, Zhijun

Li. 2016. “Application of MEMS Accelerometers and Gyroscopes in Fast

Steering Mirror Control Systems”. Sensors

16(4): 440. ISSN 1424-8220. DOI: https://doi.org/10.3390/s16040440.

12. Umeda Akira, Mike Onoe, Kohji

Sakata, Takehiro Fukushia, Kouichi Kanari, Hiroshi Iioka. Toshiyuki

Kobayashi. 2004. “Calibration of three-axis accelerometers using a

three-dimensional vibration generator and three laser interferometers”. Sensors and Actuators A: Physical

114(1): 93-101. ISSN: 0924-4247. DOI:

https://doi.org/10.1016/j.sna.2004.03.011.

13. Won Peter, Farid

Golnaraghi. 2010. “A triaxial

Accelerometer Calibration Method Using a Mathematical Model”. IEEE Transactions on Instrumentation and

Measurement 59(8): 2144-2153. ISSN: 0018-9456, ISSN: 1557-9662. DOI: 10.1109/TIM.2009.2031849.

14. Zhang Liguo, Wenchao Li, Huilian Liu. 2012.

“Accelerometer Static Calibration based on the PSO

algorithm”. In 2nd International

Conference “Electronic &

Mechanical Engineering and Information Technology”. Shenyang,

China. DOI:https://doi.org/10.2991/emeit.2012.119. ISBN

978-90-78677-60-4.

Received 04.09.2019; accepted in revised form 30.10.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License