Article

citation information:

Węgrzyn, T., Jurek, A., Wszołek,

Ł., Stanik, Z. Welding mobile platforms elements made of AHSS steel in view of new

requirements in civil engineering and transport. Scientific Journal of Silesian University of Technology. Series

Transport. 2019, 103, 209-218.

ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.17.

Tomasz

WĘGRZYN[1], Adam JUREK[2], Łukasz WSZOŁEK[3], Zbigniew STANIK[4]

WELDING MOBILE

PLATFORMS ELEMENTS MADE OF AHSS STEEL IN VIEW OF NEW REQUIREMENTS IN CIVIL

ENGINEERING AND TRANSPORT

Summary. The

developing automotive industry has prompted an increase in the demand for new

welding technologies in civil engineering and transport that reduce the mass of

mobile platforms mounted on vehicles and increase their operational range at

the same time. The AHSS steels are the materials most commonly adapted for the

production of motor vehicles due to their high tensile strength. Nonetheless,

the joints created with their use are less strong from the native material.

This article examined whether the application of micro-jet cooling would alter

the mechanical properties of the welds. Based on the performed tests, joints

with better quality that passed positively in the hardness and tensile strength

evaluations were obtained. The presented research proves that the use of

additional elements in the welding process significantly affects the quality of

the obtained welds and brings satisfactory results with a greater repeatability

than before.

Keywords: civil engineering, transport,

mobile platforms, AHSS steel, micro-jet cooling, martensitic steel

1. INTRODUCTION

New trends prevailing in civil

engineering, architecture and urban planning postulate spatial limitations of

cities, creation of buildings in an appropriate scale and shaping of a strong

urban centre. In accordance with these trends and with the ever-shrinking space

available for development, constructors are obliged to design and erect higher

and higher buildings. Their construction requires the use of modernised mobile

platforms with an expanded operational range and a weight that remains

unchanged [1, 2].

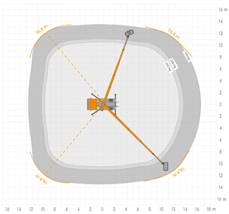

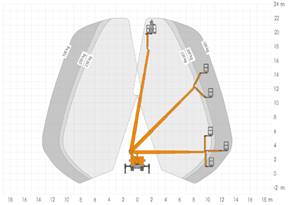

The technology of constructing mobile platforms mounted on vehicles is constantly adapting in terms of meeting changing safety standards. The revised regulations on exhaust emissions in automotive vehicles require the application of additional components such as particulate filters, exhaust catalysts, elements of exhaust systems, for example, ejectors or assisting mufflers that significantly increase their total mass. In trucks, the difference may reach up to 200 kg. Requirements imposed upon mobile platforms are presented in Figure. 1.

|

|

|

|||

|

Fig. 1.

Requirements imposed upon mobile platforms [3] |

||||

Manufacturers of mobile platforms

mounted on vehicles are constantly looking for new solutions that enable the

reduction of the extra weight of these additional elements and elevation of the

working range of these platforms. In order to increase the properties of

platform structures, another goal is to reinforce their tensile strength [3-8].

The article aims to verify whether

the use of modernised technology will allow the achievement of the

above-mentioned objectives. It is assumed that the use of micro-jet cooling

during the welding of mobile platform elements made of Advanced High Strength

Steel (AHSS) will increase the mechanical properties of the joint [9, 10].

2. MATERIALS AND METHODS

The AHSS steels are repeatedly

applied in civil engineering and transport due to their high tensile strength,

max. up to 1700 MPa, high yield strength, about 1300 MPa and high elongation

point up to 20%. AHSS steels are used mainly for thin-walled constructions as

their strength allows for the reduction of the overall weight of the structure

[11, 12]. The basic welding problem of this group of steels is that the

strength of the produced joint is much lower from the native material, despite

the steel’s good technological properties such as weldability and

machinability [13, 14].

Table 1 presents some of the AHSS

steels used for the construction of mobile platforms mounted on vehicles and

their mechanical properties.

Tab. 1

Major AHSS steels used for the

construction of mobile platforms mounted on vehicles

– mechanical properties [15]

|

Steel type |

Plasticity limit Rel (N/mm2) |

Limit of plasticity after thermal

curing min |

Tensile strength Rm (N/mm2) |

Elongation R80 % |

Min bending radius

for the angle 900 |

||

|

|

min |

max |

min |

min |

max |

min |

|

|

Docol 900M |

70 |

- |

900 |

900 |

1100 |

3 |

3,0 x grubość |

|

Docol 1200M |

950 |

- |

1150 |

1200 |

1400 |

3 |

3,0 x grubość |

|

Docol 1400M |

1150 |

- |

1350 |

1400 |

1600 |

3 |

3,0 x grubość |

|

Docol 1500M |

1200 |

- |

- |

1500 |

1700 |

3 |

3,0 x grubość |

Steels from the AHSS group are considered as difficult to weld since the

heat-affected zone (HAZ - Figure 2) is susceptible to welding cracks even when

preheated to max. 120°C [1, 11]. This is the effect of the martensitic

structure of these steels as well as the great hardness of their material.

Table 2 presents the chemical composition of some of the AHSS steels used for

the construction of mobile platforms mounted on vehicles.

Fig. 2.

AHSS steel – elements of the welded joint [3]

Tab. 2.

Major AHSS steels used for the

construction of mobile platforms mounted on vehicles

– chemical composition [16]

|

Steel type |

C% |

Si% |

Mn% |

P% |

S% |

Altot% |

Nb% |

Ti% |

|

Docol 900M |

0,05 |

0,20 |

2,00 |

0,010 |

0,002 |

0,040 |

- |

- |

|

Docol 1200M |

0,11 |

0,20 |

1,70 |

0,010 |

0,002 |

0,040 |

0,015 |

0,025 |

|

Docol 1400M |

0,17 |

0,20 |

1,40 |

0,010 |

0,002 |

0,040 |

0,015 |

0,025 |

|

Docol 1500M |

0,21 |

0,20 |

1,10 |

0,010 |

0,002 |

0,040 |

0,015 |

0,025 |

During the welding process of AHSS

steels, a decrease of mechanical properties in HAZ, as well as an increased

susceptibility to delayed cracking, may be observed. It is recommended to limit

the linear energy during welding to the level of 5 kJ/cm. In order to improve

the weldability of steel, it is proposed to introduce cooling which promotes

martensitic transformation.

The best effects when welding AHSS

steel lifts, and in particular thin-walled elements, are achieved in processes

where shielding gases or mixtures based on argon and carbon dioxide are used.

For MAG (Metal Active Gas) welding, CO2 or a mixture of Ar- CO2

are used. For TIG (Tungsten Inert Gas) welding with pure argon is adopted.

In order to improve the mechanical

properties of welded joints made of AHSS steel, we decided to use MAG welding

and the technology of micro-jet cooling. During the welding of mobile platform

elements, the following micro-jet cooling parameters were adopted:

-

number of cooling nozzles: 1,

- type of

cooling medium: Ar,

-

pressure of the cooling medium: 0.6 MPa,

-

diameter of micro stream: 70 mm,

-

distance of the micro-jet nozzle from the welded surface: 20 mm.

For tests,

the DOCOL 1200M martensitic steel from the AHSS high strength steel group was

selected due to its high strength properties. DOCOL 1200M is a material

recommended for the construction of mobile platforms mounted on vehicles. It

was expected to achieve an increased weld strength, better relative elongation

as well as an increased content of fine-grained ferrite and martensite without

the separation of bainite. For this purpose, the MAG process in combination

with micro-jet cooling was applied on the face side of the weld.

To obtain

the most favourable structure and an optimal juncture of the selected material (DOCOL 1200M from the AHSS

group) using the MAG process, the following elements were selected accordingly:

electrode wires, shielding gases as well as micro-jet cooling parameters.

In order to assess the quality of

welded joints visual tests, analysis of tensile strength, as well as structure

verification, were applied.

During the tests the following

parameters were adapted:

- two types of

shielding gases: CO2 and a mixture of 82% Ar + 18% CO2,

- two electrode

wires:

1. EN ISO 16834-A G 89 6 M21 Mn4Ni2CrMo - UNION X90 (C 0,10, Si 0,80, Mn 1,80,

Cr 0,35, Mo 0,60, Ni 2,30),

2. EN ISO 16834-A G 89 5 M21 Mn4Ni2,5CrMo

- UNION X96 (C 0,11, Si 0,78, Mn

1,9, P 0,010, S 0,009, Cr 035, Mo 0,57, Ni 2,23, V 0,004, Cu 0,02, Ti 0,057, Zr

0,001, Al 0,002).

Welding parameters for both

electrode wires and both mixtures were identical: the diameter of the electrode

wire was 1.0 mm, arc voltage 19 V, current of the welding 115 A, welding speed

300 mm/min, source of a direct current (+) at the electrode and the

single-stitch weld. In all cases, the parameters of micro-jet cooling were at

the same level: micro-jet gas - argon, stream diameter 70 mm and a gas pressure of 0.6 MPa.

3. RESULTS AND DISCUSSION

The first welding of mobile platform

elements mounted on vehicles was completed without the use of micro-jet

cooling. Figure 3 shows the method of constructing the joint.

|

|

|

|

Fig.

3. Preparation of the element for manual welding *

t=1,8 mm |

Fig.

4. The welded joint |

To assess further weldability of the

mobile platform, elements shielding gases 82% Ar + 18% CO2 as well

as both electrode wires (UNION X90 and UNION X96) were selected. The welding

process was performed using a ceramic washer. The results of the produced

connections are shown in Table 3.

Tab. 3

Mobile platform joints made with the

use of micro-jet cooling and a ceramic backing

|

Gas / wire |

UNION X90 |

UNION X96 |

|

CO2 |

Cracks in the HAZ and in

the weld |

Cracks in the HAZ and in

the weld |

|

82% Ar + 18 % CO2 |

Cracks in the HAZ |

Cracks in the HAZ |

Subsequent tests were carried out

using shielding gases 82% Ar + 18% CO2 and both electrode wires

(UNION X90 and UNION X96), together with the use of a copper backing and an

argon micro-jet cooling. The results of the produced connections are shown in

Table 4.

Tab. 4

Mobile platform joints made with the

use of argon micro-jet cooling and a copper backing

|

Gas / wire |

UNION X90 |

UNION X96 |

|

CO2 |

Cracks in the HAZ and in

the weld |

Cracks in the HAZ |

|

82% Ar + 18% CO2 |

No cracks in the HAZ |

No cracks in the HAZ |

After the completion of all welding tests,

visual tests of welds were carried out (Figures 5 and 6).

|

|

|

|

(a) |

(b) |

|

|

|

|

(c) |

|

|

Fig. 5. Visual condition

of the welds after MAG welding |

|

|

|

|

|

(a) |

(b) |

|

|

|

|

(c) |

|

|

Fig. 6. Visual condition

of the welds after welding with the use of micro-jet cooling |

|

The use of micro-jet cooling

delivered much better results. The method produced a better quality of welds,

without any visible bumps. Afterwards, the welded elements of the platform were

inspected for stretching. The strength of the connections was tested using the

INSTRON 3369 testing machine. The following analyses were carried out:

-

strength of DOCOL 1200M steel without the use of micro-jet cooling,

-

strength of DOCOL 1200M steel with the use of micro-jet cooling.

Each test was repeated 3 times

(samples 1, 2, 3).

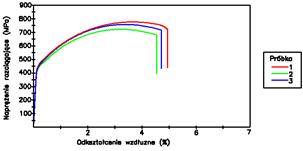

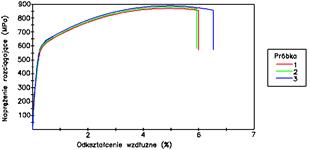

The results of the strength tests

are presented in Figures 7 and 8 and in Tables 5 and 6.

|

|

|

|

Fig.

7. The results of the AHSS steel joint strength test welded with MAG method |

Fig.

8. The results of the AHSS steel joint strength test welded with MAG method

and micro-jet cooling |

Tab. 5

Results of the DOCOL 1200M steel

strength tests after welding without the use of micro-jet cooling

|

Sample |

Re [MPa] |

Rm [MPa] |

A5 |

|

1 |

451 |

765 |

4,3 |

|

2 |

446 |

722 |

4,2 |

|

3 |

450 |

751 |

4,1 |

|

Median |

449 |

746 |

4,2 |

Tab. 6

Results of the DOCOL 1200M steel

strength tests after welding with the use of micro-jet cooling

|

Sample |

Re [MPa] |

Rm [MPa] |

A5 |

|

1 |

556 |

890 |

5,7 |

|

2 |

548 |

893 |

5,9 |

|

3 |

552 |

887 |

5,8 |

|

Median |

552 |

890 |

5,8 |

The average Re value of

the MAG welded joint was 449 MPa and the average Rm value was 746

MPa. As a result of micro-jet cooling used during the welding process, Re

and Rm values increased accordingly to Re =552 MPa and Rm

=890 MPa.

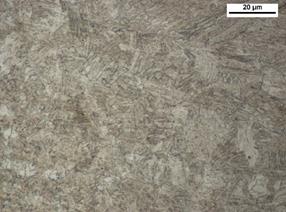

Thereafter, the microstructure

analysis was performed. The microstructure of the cross-section of the weld

with a visible martensitic structure is shown in Figures 9 and 10.

|

|

|

|

Fig.

9. Microstructure of the weld cross-section without the use of micro-jet

cooling |

Fig.

10. Microstructure of the weld cross-section with the use of micro-jet

cooling |

Figure 9 presents visible

martensite, coarse ferrite and bainite. This is an unfavourable structure

causing inferior plastic properties (relative elongation is at the level of

4%). Martensite and fine-grained ferrite are visible in Figure 10. This

structure is more advantageous: allows obtaining of better plastic properties

(with the relative elongation at the level of 6%), and elimination of cracks in

the joint and in the heat affected zone.

4. CONCLUSIONS

Civil engineering and transport designate new

requirements for the constructors of mobile platforms. A need for new welding

technologies that significantly reduce the weight of mobile platforms mounted

on vehicles and increase their operating range and lifting capacity at the same

time is constantly growing.

Material that is

increasingly used for mobile platforms manufacturing is the hard-to-weld AHSS

steel. Its high strength is almost double from the strength of the welded

joint. The relative elongation obtained in the previously used processes is

low, which indicates poor plastic properties of the joint. Therefore, new

solutions that aim to improve the weldability of thin-walled AHSS steel

structures, increase the tensile strength and expand the relative elongation at

the same time are being sought.

The increase of the operational parameters

(such as load capacity and range) while maintaining the mass of mobile

platforms mounted on vehicles can be obtained by modifying the AHSS steel

welding technology. The research presented in this article proves that the use

of micro-jet cooling enables production of better quality welds with much

higher repeatability than before. This technology requires, however, further

development and additional research. With the appropriate selection of

technological parameters of MAG welding and micro-jet cooling (type of

micro-jet gas), it will be possible to determine the welding criteria for

various steel grades used in the construction of mobile platforms.

References

1.

Macioszek Elżbieta. 2018. “The comparison of models for follow-up

headway at roundabouts”. In Macioszek Elżbieta, Sierpiński Grzegorz

(eds.). Recent Advances in Traffic

Engineering for Transport Networks and Systems. Lecture Notes in Networks and

Systems 21: 16-26.

Switzerland: Springer International Publishing. ISBN 978-3-319-64084-6.

2.

Macioszek Elżbieta. 2018. “First and last

mile delivery - problems and issues”. In Sierpiński Grzegorz

(ed.). Advanced Solutions of Transport

Systems for Growing Mobility. Advances in Intelligent Systems and Computing

631: 147-154. Switzerland: Springer International Publishing. ISBN

978-3-319-62316-0.

3.

AHSS

steel – elements of the welded joint. Available at: http://www.kkmito.zut.edu.pl/dydaktyka/urbanski/spaw-podstawy.html.

4.

Celin

Roman, Burja Jaka. 2018. “Effect of cooling rates on the weld heat

affected zone coarse grain microstructure”. Metallurgical and Materials Engineering 24(1): 37-44. DOI:

https://doi.org/10.30544/342.

5.

Darabi

Jafar, Ekula Kishore. 2003. “Development of a chip-integrated micro

cooling device”. Microelectronics

Journal 34(11): 1067-1074. DOI: https://doi.org/10.1016/j.mejo.2003.09.010.

6.

Hadryś

Damian, Jan Piwnik, Wojciech Majewski. 2014. “Plastic properties of welds

after micro-jet cooling with different cooling gases”. Advanced Materials Research 1036:

446-451. DOI: https://doi.org/10.4028/www.scientific.net/AMR.1036.446.

7.

Jacyna Marianna, Mariusz Izdebski, Emilian Szczepański, Paweł

Gołda. 2018. „The task assignment of vehicles for a production

company”. Symmetry-Basel

10(11). Article number: 551.

8.

Krayushkina Kateryna, Olegas Prentkovskis, Andrii Bieliatynskyi,

Raimundas Junevičius. 2012. “Use of steel slags in automobile road

construction”. Transport 27(2):

129-137.

9.

Hadryś

Damian. 2015. “Impact load of welds after micro-jet cooling”. Archives of Metallurgy and Materials

60(4): 2525-2528. DOI: https://doi.org/10.1515/amm-2015-0409.

10.

Muszynski

Tomasz, Dariusz Mikielewicz. 2017. “Structural optimization of microjet

array cooling system”. Applied

Thermal Engineering 123: 103-110. DOI:

https://doi.org/10.1016/j.applthermaleng.2017.05.082.

11.

Szczucka-Lasota

Bożena. 2016. “Innovation in the process of thermal spraying

coatings”. Archives of Metallurgy

and Materials 61(3): 1431-1436. DOI: https://doi.org/10.1515/amm-2016-0234.

12.

Tarasiuk

Wojciech, Bożena Szczucka-Lasota, Jan Piwnik, Wojciech Majewski.

“Tribological properties of super field weld with micro-jet

process”. Advanced Materials

Research 1036: 452-457. DOI:

https://doi.org/10.4028/www.scientific.net/AMR.1036.452.

13.

Walsh

Stephen, James Smith, Eric Browne, Timothy Hennighausen, Bernard Malouin. 2018.

“Practical concerns for adoption of microjet cooling”. ASME Proceedings 2018 Power Electronics,

Energy Conversion, and Storage. ASME. ISBN: 978-0-7918-5192-0. DOI:

https://doi.org/10.1115/IPACK2018-8468.

14.

Szczucka-Lasota

Bożena, Jan Piwnik. 2017. “New technological concept for thermal

spray protective coatings”. Archives

of Metallurgy and Materials 62(3): 1499-1504. DOI:

https://doi.org/10.1515/amm-2017-0232.

15.

YUMPU. Available at: https://www.yumpu.com/docol-m-zimnowalcowana-stal-martenzytyczna-ssab.

16.

RUTHMANNSTEIGER. Available at:

https://www.ruthmann.de/produkte/steiger.

Received 09.01.2019; accepted in revised form 10.05.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License