Article

citation information:

Vinogradov, B. Mechanical systems with

air spring flexible elements. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 103, 199-207. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.103.16.

Borys VINOGRADOV[1]

MECHANICAL

SYSTEMS WITH AIR SPRING FLEXIBLE ELEMENTS

Summary. The purpose of this study was to assess the

effectiveness of flexible air-spring systems operating in parallel to share the

total load, taking into account installation and in-operation errors. This

study presented experimental and calculated characteristics of the air spring

flexibility and its dependence on the polytropic index and additional volume.

It considered patterns of load distribution between the air springs when they

are operating in parallel to share the total load for the case when the air

springs were used as the supporting elements for various machines and units,

and between transmission lines containing flexible couplings, where air springs

were installed as flexible elements.

Keywords: air spring, rubber-cord shell, load distribution, flexible

1. INTRODUCTION

A wide standard size series of rubber-cord air springs with a load

capacity from 350 N to 230,103 Nwas developed and is being produced. Prospects

for effective use of air springs as hydraulic inertial transducers of motion

[1], vibration dampers and shock absorbers for rail vehicles [2] are being

considered. The use of pneumatic couplings in machine drives solved the problem

of limiting dynamic loads [3, 7]. One of the most important features of

pneumatic couplings is the ability to control their stiffness and, accordingly,

torsional vibrations of mechanical systems [4]. Furthermore, air springs may be

effectively used as flexible elements sharing the total load, and in systems

with a branched power flow.

2.

FLEXIBILITY CHARACTERISTICS OF AIR SPRINGS

When choosing a reference

point in the static equilibrium position, the characteristics of the air spring flexibility has the form

![]() (1)

(1)

where ![]() ,

, ![]() are the gas volume and overpressure in the air spring bellows in the static equilibrium position;

are the gas volume and overpressure in the air spring bellows in the static equilibrium position; ![]() is atmospheric pressure;

is atmospheric pressure; ![]() is the air spring effective area depending on the

displacement x.

is the air spring effective area depending on the

displacement x.

The experimental studies of the flexibility

characteristics were carried out for the Connect MD 1895 double convolution air spring, according to the

manufacturer’s company catalogue, its features are:

weight - 2.95 kg; working pressure - 0.5 MPa; maximum pressure - 0.8 MPa;

minimum pressure - 0 MPa; working diameter - 265 mm; assembly height 210 mm;

load capacity - 900 kg. The internal volume of the air spring with its design height of 140 mm

is 3.64 litres. Based on experimental studies, the dependence of the air spring

effective area on its deformation is represented by a first-order polynomial.

![]() (2)

(2)

where ![]() is the

effective area in the static equilibrium position, m2, P is the external load, β = 0.118 m.

is the

effective area in the static equilibrium position, m2, P is the external load, β = 0.118 m.

The difference between

the experimental and calculated flexibility of the air spring, when compared by

the formula (1) given (2), does not exceed 2%, which allows for further

consideration of it as an actual flexibility [5].

Expanding the expression

(1) considering (2) in a Taylor series and retaining only the first two terms,

we obtain

![]() , (3)

, (3)

where

![]() ,

,

![]() (4)

(4)

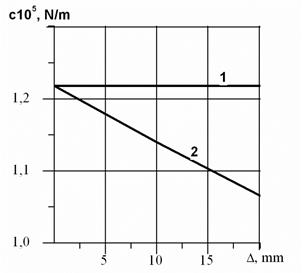

Figure 1 shows the

linearised flexibility characteristics, determined by the formula (4), with the

actual flexibility determined by the formula (1)

The rubber-cord flexible element is a closed system, where heat will be evolved due to internal air friction during

each cycle of air compression

and expansion. The value of the polytropic index depends on the conditions of heat removal. The environmental conditions being the same, the number of compression and

expansion cycles over the same time period grows with an increase in the vibration frequency; with the lack of proper heat removal, the polytropic index can take values n > 1.4. In most cases, the calculations take n = 1.3. As n

increases, for example, from 1.3 to 1.6, as it follows from expression (4), the air spring stiffness and the natural frequency increase by

1.13 (Figure 2a) and 1.06

times, respectively, which in practice can be neglected in most cases.

Fig. 1. Actual and

linearised flexibility characteristics of the air spring

|

|

|

|

а |

в |

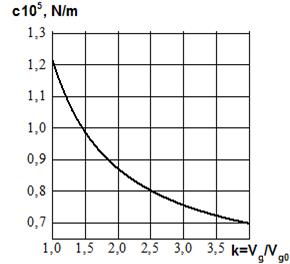

Fig. 2. The

dependence of the air spring stiffness on the polytropic index (a) and the

additional volume (b): k is the ratio

of the total volume of gas (including the added gas) to the initial volume

The rubber-cord flexible element is a closed system, where heat will be evolved due to internal air friction during

each cycle of air compression

and expansion. The value of the polytropic index depends on the conditions of heat removal. The environmental conditions being the same, the number of compression and

expansion cycles over the same time period grows with an increase in the vibration frequency; with the lack of proper heat removal, the polytropic index can take values n > 1.4. In most

cases, the calculations take n = 1.3. As n increases, for example, from 1.3 to 1.6, as it follows from expression (4), the air spring stiffness and the natural frequency increase by

1.13 (Figure 2a) and 1.06

times, respectively, which in practice can be neglected in most cases.

One of the advantages of

systems that use air springs as flexible elements is the ability to control

their flexibility by adding an additional volume (Fig. 2b)

3. LOAD DISTRIBUTION

BETWEEN AIR SPRINGS OPERATED IN PARALLEL TO SHARE THE TOTAL LOAD

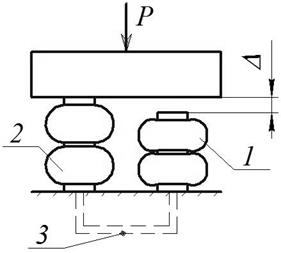

Consider the case where air springs are used as support for various

machines and units. These mechanical systems include

vibratory machines or other aggregates that apply air springs as flexible elements. This is the case, where installation errors may occur when the support of one air spring is displaced by Δ relative to the other (Fig. 3).

When pressure is

supplied to the bellows of each air spring, the error is compensated and the

air springs will attain equal pressures. Interconnected air springs adjust the pressure automatically. In the state of static equilibrium position, the first air spring will undergo a deformation smaller by the value of

Δ. As a result, the effective areas of the air springs in the static equilibrium position

will be different;

pressures pm0 being the same, the load between the air springs will not be uniformly distributed.

Fig. 3.

Flexible system with air springs mounted in parallel: 1, 2 - air springs; 3 -

common pipeline; P - external load; Δ - the error

For the case of independent

operation of air

springs, the

equilibrium equations will take the form:

![]() ,

, ![]() ,

, ![]() ,

,

where ![]() ,

, ![]()

Substituting S (x1),

S (x2), p1 , p2 from (1), we obtain the system of equations

![]() , (5)

, (5)

![]() , (6)

, (6)

The value of x in the static equilibrium position is determined from the

following condition:

+![]() .

.

When linearising the flexibility characteristics, the stiffness of the air springs is determined by the following expressions

![]() ,

,

(7)

![]()

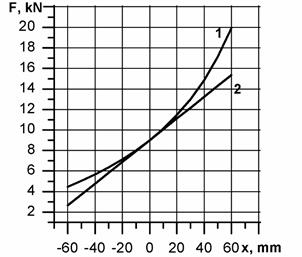

The calculated values of the

linearised air

spring stiffnesses versus the magnitude of the error Δ are

shown in Figure 4.

Fig. 4.

Dependence of the air spring stiffness on the error Δ for independent air springs, the

initial pressures pm0 being

equal

The calculated data showed that the mounting errors, in this case, have little effect on the change in

stiffness. Even with an error of 20 mm, the stiffnesses of the air springs differ by no more than 1.2 times.

In the static equilibrium position, the air springs will take the force

![]() ,

, ![]() (8)

(8)

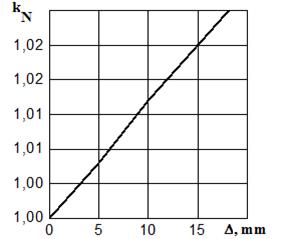

The non-uniform distribution of the load will be characterised by the coefficient kN, which shows how many times the force

taken by the most loaded air spring exceeds the force taken under a uniform distribution of the

total load

![]() (9)

(9)

Considering that с2 > с1, Fmax = F2,

we obtain

![]() . (10)

. (10)

When ![]()

![]()

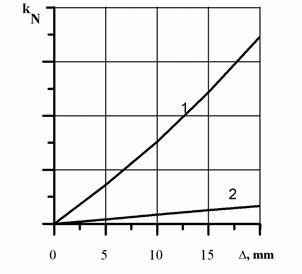

The dependence of the non-uniform load distribution factor kN on the magnitude of the error

Δ is shown in Figure 5.

Fig. 5. The dependence

of the non-uniformity factor kN

on the error Δ, the initial pressures pio being equal

As can be seen from the

expression (11) and (14), in this

case, the non-uniform load was only caused by a change in the effective

area, which, in turn, is caused by the mounting error.

Analyzing the data obtained,

we can conclude that the use of air springs as flexible elements operating in parallel ensures a practically

uniform distribution of the load between them. Even with an error Δ = 20 mm, the non-uniform distribution of load is about 3%.

4. LOAD DISTRIBUTION BETWEEN

TRANSMISSION LINES INCORPORATING PNEUMATIC FLEXIBLE COUPLINGS

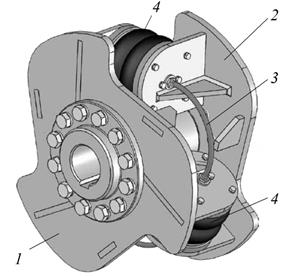

As an example, we considered a twin-motor synchronous drive, whose transmission lines incorporate couplings with air springs installed as flexible elements (Fig. 6). Figure 1 shows a flexible coupling (pneumatic coupling) developed by the Polish

company, FENA, at the Technical University in

Košice (Slovakia) [5].

The feature of the synchronous drive is that the

rotational speed of the motors does not depend on the load. At the moment, when the motors come into synchronism, their rotors may undergo angular

displacement in respect to each other; this leads to an error, which we will further call an “angular mismatch”. By the angular mismatchDj, we understood the angle by which it is necessary to align the rotors

of the engine in order to provide a uniform load distribution. Misalignment of

the rotors may also be caused by the take-up of clearances in the kinematic

chain.

The force taken by each air spring is determined by the following expressions:

![]() , (11)

, (11)

![]() , (12)

, (12)

![]() +

+

+![]() . (13)

. (13)

Fig. 6.

Flexible pneumatic coupling:

1 - drive

part; 2 - driven part; 3 - pipeline; 4 - pneumatic flexible elements

(rubber-cord air springs)

The variation of the non-uniformity factor versus the error for this case is shown in Figure 7.

In the case, when the bellows of the air springs of each coupling are interconnected, the mismatch of the motor rotors will be compensated by

stretching the air spring bellows in the coupling of the first motor transmission line and compressing the air spring bellows in the coupling of the other motor transmission line, the pressure within the air springs being the same [6].

As a result, the non-uniform load distribution between the motors will only be due to the different effective

areas of the air

springs in the couplings; it can be determined by the formula (10). With a relatively high error Δ =

20mm, the non-uniform

load distribution

will be about 3% (Figure 7). An absolutely uniform load distribution

can be achieved by using an automatic system that enables control of the pressure within the bellows of the air springs [6].

Fig. 7. The load distribution

factor versus the magnitude of the angular mismatch of the synchronous motor

rotors ∆ = r∆φ0, (r is the

coupling radius): 1, 2 - couplings with independent and interconnected air

springs, respectively

5. CONCLUSIONS

1.

In the operation of pneumatic systems, the

polytropic index n will change

depending on the conditions of the heat removal. With an increase in n, for example, from 1.3 to 1.6, the air

spring stiffness will increase by 1.13 and the natural frequency by 1.06 times,

which in most cases can be neglected in practice.

2.

In cases, when the air springs are mounted

in parallel to support the total load, the load will be almost uniformly

distributed between the air springs, even with equal initial air pressures in

their bellows, and in spite of the relatively bad mounting errors (20 mm).

3.

The use of flexible couplings in

mechanical systems with branched power flows, for example, in twin-motor

synchronous drives where air springs are used as flexible elements, allows an

even distribution of the load between the transmission lines.

References

1.

Buryan

Yu.A., V.N. Sorokin, M.V. Silkov, Yu.F. Galuza. 2015. “Hydraulic inertial

motion transformer with rubber-cord casing”. Omsk Scientific Bulletin

1(137): 30-33.

2.

Manashkin

L., S. Myamlin, V. Prikhodkoю 2009. Oscillation

dampers and shock absorbers in railway vehicles (mathematical models).

Dnipropetrovsk. 180 p. DOI: 10.15802/978-966-348-121-0.

3.

Czech P. 2012. „Determination of the course of pressure in an

internal combustion engine cylinder with the use of vibration effects and

radial basis function - preliminary research”. Communications in Computer and Information Science 329: 175-182. 12th International

Conference on Transport Systems Telematics (TST 2012). Katowice-Ustron, Poland,

October 10-13, 2012. Telematics In The Transport Environment. DOI: https://doi.org/10.1007/978-3-642-34050-5_21.

4.

Sága M., L.

Jakubovičová. 2014. “Computational analysis of contact stress

distribution in the case of mutual stewing of roller bearing rings”. Novel Trends in Production Devices and

Systems, Applied Mechanics and Materials 474: 363-368.

5.

Sapietova

A., V. Dekys. 2016. „Use od Msc. Adams software product in modeling

vibration sources”. Komunikacie

1a(101): 101-107.

6.

Urbanský

M., J. Homišin, P. Kaššay, J. Krajňák. 2018. „Measurement of air springs volume using indirect method in the design of

selected pneumatic devices”. Acta

Mechanica et Automatica 12(1): 19-22. ISSN 1898-4088.

7.

Żółtowski

B., M. Żółtowski. 2018. “Selection measure of energy

propagation in vibration diagnostic and modal analysis methods”. Diagnostyka 19(4):19-26. DOI: 10.29354/diag/94753.

Received 19.01.2019; accepted in revised form 05.05.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License