Article

citation information:

Hadryś, D., Kubik, A., Stanik,

Z., Łazarz, B. Deceleration and deformation during dynamic load of model longitudinals –

real conditions and simulation. Scientific

Journal of Silesian University of Technology. Series Transport. 2019, 102, 53-64. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2019.102.4.

Damian HADRYŚ[1], Andrzej KUBIK[2], Zbigniew STANIK[3], Bogusław

ŁAZARZ[4]

DECELERATION AND DEFORMATION DURING DYNAMIC LOAD OF MODEL LONGITUDINALS - REAL CONDITIONS AND SIMULATION

Summary. The manner and degree of

taking over impact energy by the passive safety elements of the vehicle body is

the basis for providing conditions for the survival of people using the means

of transport (driver and passengers). The elements specially designed for this

purpose in the self-supporting body are longitudinals. Their energy-absorbing

properties are designed by using a specific shape, by using appropriate

connections of their components and by choosing the right material. Determining

the degree to which the vehicle (body) ensures safety during collision requires

testing. The most complex and expensive tests are the ones carried out on a

complete real object (whole vehicle). The solution worth considering is a bench

test of individual body elements designed as energy-consuming (for example,

longitudinals). In addition, it is also possible to carry out computer

simulations in this area. The purpose of this article was to present and

compare the results of dynamic studies on model energy-consuming real objects

and compare the results obtained this way with the results of computer

simulation in the same range. The scope of work was adopted on this basis:

passive safety, model energy-absorbing elements of steel self-supporting

vehicle body, dynamic tests, computer simulations. For the purpose of this

study, a model of vehicle passive safety elements (model longitudinals) was

designed for which dynamic tests were carried out on a specially designed test

stand (speed of the hammer was up to 9.7 m/s, impact energy was up to 23.6 kJ).

This test stand enabled registration of the deceleration during impact and

deformation of the tested object. Next, computer simulations were carried out

for geometrically and material-identical models. On the basis of the conducted

tests, it was found that it is worth considering the replacement of collision

tests of the whole vehicle by tests of its individual components. These tests

can also be supported by computer simulations.

Keywords: longitudinal, passive

safety, impact energy, dynamic load, simulation

1. INTRODUCTION

According to the currently valid

concept of a safety bodywork, the vehicle has zones that are supposed to be

deformed during a crash. The degree and way of deformation depend on the energy

of the vehicle at the moment of impact (the actual mass of the vehicle and the

velocity of impact are very important). All of the elements in the deformation

zones during their deformation absorb the impact energy. For example, both the

bumper and the external fender deformed during the collision absorbed some of

the vehicle energy. The difference is in their energy-consuming abilities

[1÷3].

In crash control zones

energy-consuming elements are intentionally placed. They are designed in such a

way that during the collision, they are deformed and absorb as much of the

vehicle's energy as possible. The vehicle components included in the crash

control zones can be divided basically into two groups. The first group

includes elements that have been deliberately designed and used to absorb

impact energy (for example, crash box). The second group includes elements that

in addition to their basic task have been designed in a way that ensures their

energy-consuming properties (for example, longitudinals). The basic elements

included in the crash control zones include, among others: bumpers and

sub-bumper beams, crash boxes, a front partition, longitudinals and the bonnet

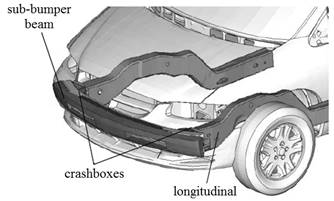

(Figure 1).

Fig. 1. Elements of the

crash control zone [4]

2. LONGITUDINALS

Longitudinals are the basic elements

in the construction of a self-supporting vehicle body. They combine several

functions. The most important of them are undoubtedly the functions of the

load-bearing element for the engine or the whole drive unit, as well as the

suspension of the front vehicle. Due to the fact that the stringers now appear

in almost every car body, and because of their shape and characteristic

location in the vehicle, they were entrusted with an additional task -

absorbing the collision energy during a car crash. As research shows, mainly

longitudinals take over the impact energy. For this reason, their role in the

aspect of passive safety of car body and whole vehicle safety is very important

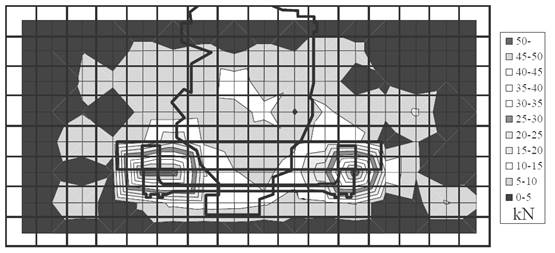

(Figure 2).

Fig. 2. The results of

measurements of the impact force of a passenger car in a rigid barrier at a

speed of about 50 km/h [5]

Longitudinals in the

self-supporting body can be treated as a remnant from times when frame

constructions prevailed.

However, the geometrical shapes of

the modern longitudinals as members of the self-supporting body do not resemble

unfinished longitudinals from frame structures made as one element. The

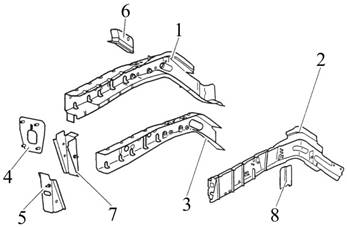

longitudinal of the currently produced passenger cars generally has a closed

cross-section. It is composed of at least two extrudates. In addition, a series

of additional elements may be included in the longitudinal member (Figure 3).

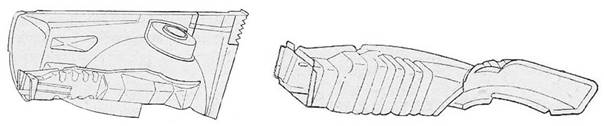

During the design of the

geometrical shapes of the longitudinal, the constructor may in a sense,

programme the manner and course of its deformation during the collision (Figure

4). This, of course, has an effect on the value of deformation of the body and

the value of deceleration as it affects the users of the vehicle. In order to

give the longitudinal a shape that ensures the optimal manner and course of

deformation, a series of ribs or holes were formed as geometric notches. It is

in these places that the deformation of the longitudinal will be initiated

during the impact.

An important issue regarding the

longitudinals in a self-supporting car body is the way in which they are

combined with the whole car body integrity. The method of transferring forces

from the longitudinal to the rest of the car body depends on the solution of

this construction node. In principle, it is possible to distinguish

longitudinals passing into the floor pane and longitudinals extending to the

thresholds.

Fig. 3. Citroen C8 left

front member: 1. longitudinal member, 2. side member, 3. side member

reinforcement, 4. bracket, 5. end of the longitudinal member, 6. longitudinal

strut, 7. side member, 8. reinforcement stringer closing [6]

Fig. 4. Longitudinal

with a given deformation solution [7]

3. INVESTIGATION

AND RESULTS

Two types of investigations were

carried out. These are; dynamical test and computer simulation.

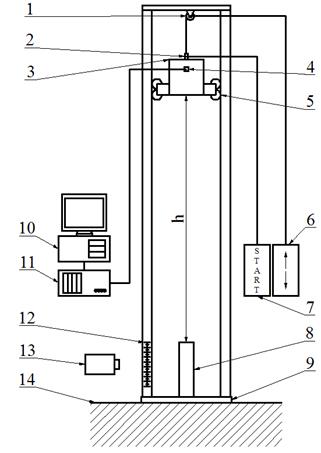

Dynamical test was done using a

special test stand [8÷12]. Main characteristics of the test stand for

the dynamic test are shown in Table 1. Test stand is shown in Figure 5.

Tab. 1.

Characteristics

of the test stand for the dynamic test

|

Ram mass |

to |

|

Impact velocity |

to 9.7 m/s (to |

|

Free fall height |

to 4.8 m |

|

Impact energy |

to 23.6 kJ |

Fig. 5. Schematic

diagram of the test stand for dynamic testing of model car body elements, h –

height of free fall of the ram, 1. hoist, 2. trigger, 3. ram, 4. deceleration sensor,

5. guide rollers, 6. hoist panel, 7. trigger device, 8. model longitudinal, 9. base

of the test stand, 10. computer, 11. device for data acquisition, 12. graduation,

13. camera, 14. foundations.

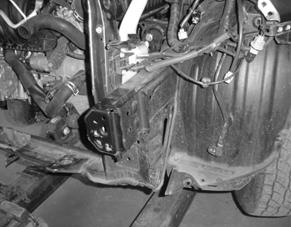

Model longitudinals were done for

dynamic investigation. It consists of a few steps. In the beginning,

investigations of the real form of longitudinals were done. Examples of its

results are portrayed in Figure 6.

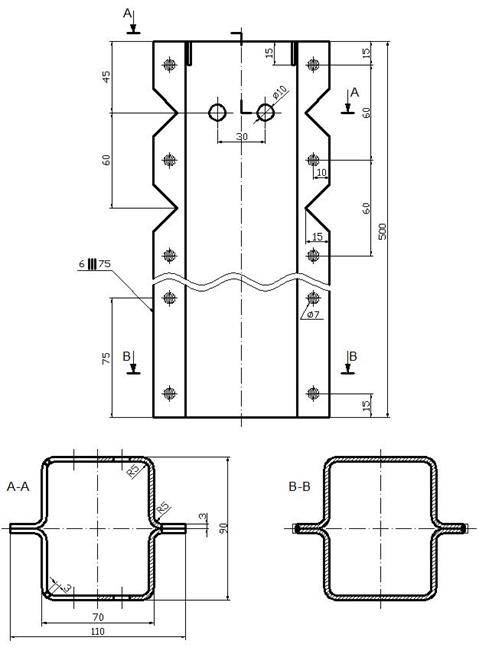

Next model of longitudinals was

designed. In this step, some main model features were set (shape – Figure

7, material – Table 2, joint characteristics – Tables 3 and 4). The

material used was typical steel of increased strength. The model longitudinal

was 0.5 meter long and their cross-section was close to the pair of Ω

profile. Incisions were made in the corners as deformation initiation elements.

Additionally, through holes and edge cuts were made in the walls of the model

longitudinal.

Fig. 6. Example of

observed real longitudinals of a car body

In general, spot welding was used

to connect the parts of the model longitudinal. In order to obtain the gradation

of stiffness of the model longitudinal, marginal welds at the end of it were

made. The parameters of point resistance welding are shown in Table 2, while

welding parameters in gas shields are shown in Tables 3 and 4.

Tab. 2.

The

chemical composition of the steel from which the model longitudinal were made

|

Steel grade |

Chemical composition,

% |

||||

|

S355J2G3 |

C |

Mn |

Si |

P max |

S max |

|

0.2 |

1.45 |

0.51 |

0.035 |

0.035 |

|

Tab. 3.

Parameters of point

resistance welding

|

Diameter of

electrodes, mm |

Current, kA |

The force of electrode

pressure, kN |

Welding time, s |

|

8.6 |

18.8 |

3 |

0.45 |

Tab. 4.

Metal Active Gas (MAG)

welding parameters

|

Shielding gas |

Gas flow rate, dm3/min |

The diameter of the

electrode wire, mm |

Current, A |

Voltage, V |

Wire feeding speed, m/min |

|

82% Ar + 18% CO2 |

16 |

1.2 |

150 |

25 |

11 |

Fig. 7. Model

longitudinal

The advantages of the designed test

stand for dynamic test is that the velocity of impact can be smoothly adjusted

and free fall mass can be gradually changed. In addition, it is possible to

study model energy-absorbing elements of the car body as well as elements of

the real self-supporting car body.

According to the main assumption

regarding the method of testing, during the impact process, the deceleration of

free fall mass and the deformation of the tested element are recorded as a

function of time. Deceleration was measured by a single axis deceleration

sensor. Deformation was measured by a speed camera.

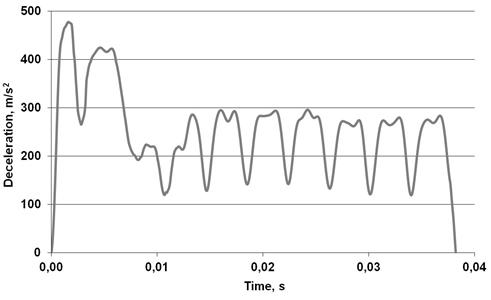

In Figure 8-11 examples of results

obtained during dynamical tests are shown. These figures illustrate the first

phase of the impact (compression). There are:

·

value of deceleration of RAM in depends on

time during impact.

·

value of velocity of RAM in depends on

time during impact.

·

value of model longitudinal deformation in

depends on time during impact.

The duration of the impact process

(first phase of the impact) was about 0.038 s. The maximum value of the

deceleration during impact was about 480 m/s2. The maximum value of the

deceleration was observed at the beginning of the impact process. It is a

characteristic feature of the time course of the deceleration during impact.

This is due to the fact that at the beginning of the impact the test piece

(model longitudinal) exhibited the highest stiffness. The time course of the

deceleration had a specific shape (characteristic changes in the parameter

value). This was due to the predetermined deformation of the model longitudinal

during the collision.

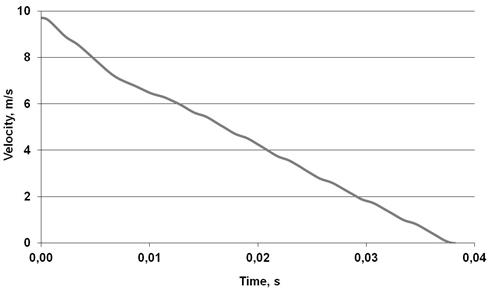

The changes in the speed of the RAM

are similar to linear. Slightly higher intensity of velocity decreasing can be

observed only at the beginning of the impact. As already mentioned, it is

caused by the stiffness of the tested element (model longitudinal) at the

beginning of the impact (initiation of deformation).

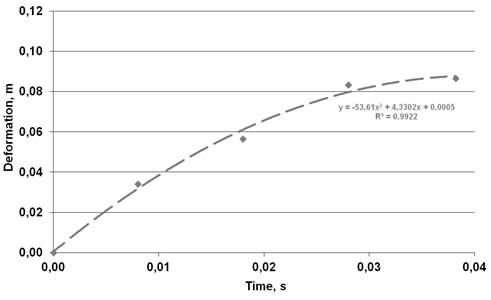

The change in the value of model

longitudinal deformation in depends on time during impact can be described as

square function. At the beginning of the impact process, the increases in the

deformation value are clearly greater than at the end of the process. This is

due to the fact that at the beginning of the impact, the RAM had great velocity

and therefore great kinetic energy. The maximum deformation value of the tested

component (model longitudinal) is approximately 88 mm.

Fig. 8. Value of

deceleration of RAM in depends on time during impact (Example)

Fig. 9. Value of

velocity of RAM in depends on time during impact (Example)

Fig. 10. Value of model

longitudinal deformation in depends on time during impact (Example)

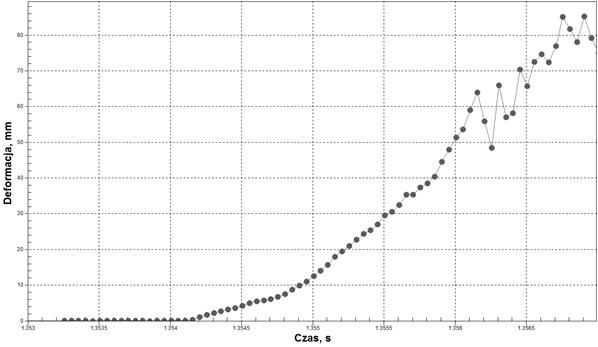

Next part of the test was a

computer simulation. It was done using the Autodesk Simulation Mechanical 2017.

Simulations reproduce identical experimental conditions as in real samples on

model objects (model longitudinals). Examples of the results obtained during

computer simulations are presented in Figures 11 and 12.

It should be noted that the results

obtained during computer simulation are similar in value to the results of

tests on the real model longitudinal (Figures 11 and 13).

Fig. 11. Examples of

model longitudinal after tests

Fig. 12. Examples of

computer simulation results

Fig. 13. Value of model

longitudinal deformation in depends on time during impact (Example of computer

simulation)

4. SUMMARY

The aim of this paper was to

present and compare the results of dynamic studies on model energy-consuming

real objects and compare the results obtained this way with the results of

computer simulation within the same range.

For investigation simplified test

stand was designed and constructed (experimental research stand). Moreover, a

computer simulation was done for similar conditions.

On the basis of this investigation,

it is possible to conclude that:

· passive safety of the

car body is a very important subject.

· longitudinal is the

component which absorbed a lot of impact energy.

· it is possible to carry

out crash tests on individual components of the car body (instead of the whole

car).

· the time course of the

impact deceleration has a characteristic shape (high values at the beginning of

the process and subsequent variations of the parameter value).

· it is possible to carry

out a computer simulation of the impact process, and the results obtained there

are comparable to those on real objects (values of parameters).

References

1.

Romaniszyn K.M. 2006. „Wpływ struktury przodu nadwozia

na energochłonność”. [In Polish: „The influence of the structure

of the front of a car chassis on its energy dissipation”]. Zeszyty Naukowe Politechniki

Świętokrzyskiej, Mechanika z. 84: 287-292.

2.

Baranowski P.,

R. Burdzik,

J. Piwnik. 2011. „Measure and analysis of crash

vehicle deformation”. Aparatura Badawcza

i Dydaktyczna 16(1): 11-16.

3.

Gill A. 2001. „Ocena skuteczności działania

elementów bezpieczeństwa biernego samochodów osobowych na

podstawie wyników badań zderzeniowych”. [In Polish: “Efficiency assessment

of passive safety elements in passengers cars on the base of crash tests

results”]. Zeszyty Naukowe Politechniki

Poznańskiej, Maszyny Robocze i Transport 53: 117-123.

4.

TopSpeed.

Available at: http://www.topspeed.com/cars.

5.

Arai Y., K. Yamazaki, K. Mizuno, H. Kubota. „Full-width tests to evaluate

structural interaction”. 20th International Technical

Conference on the Enhanced Safety of Vehicles (ESV). Lyon , France, 2007-6-18

to 2007-6-21. Paper Number 07-0195.

6.

Technical

data and training materials of Citroen, Model C8, PSA 2006.

7.

Kobus W. 1987. Nowe metody

napraw nadwozi samochodów osobowych. [In Polish: New

methods for repairing passenger car bodywork]. WKił:

Warsow.

8.

Song H.W., Z.M. Wan, Z.M. Xie, X.W. Du. 2000. “Axial impact behavior and energy

absorption efficiency of composite wrapped metal tubes”. International Journal of Impact Engineering

24(4): 385-401.

9.

Juntikka

R., S. Hallstrom. 2004. „Weight-balanced drop test method for

characterization of dynamic propertiesof cellular materials”. International Journal of Impact Engineering

30(5): 541-554.

10. Peroni L., M. Avalle, G. Belingardi. 2008.

„Comparison of the energy absorption capability of crash boxes assembled

by spot-weld and continuous joining techniques”. International Journal of Impact Engineering 36(3): 498-511.

11. Tobota

A., J. Karliński, A. Kopczyński. 2007. „Axial crushing of monotubal and bitubal

circular foam-filled sections”. Journal

of Achievements in Materials and Manufacturing Engineering 22(2): 71-74.

12.

Dahil

L. 2017. “Effect on the vibration of the suspension system”. Metalurgija

56(3-4): 375-378.

Received 12.11.2018; accepted in revised form 11.01.2019

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License