Article

citation information:

Więckowski, A. Automating the

construction of bus bays with reinforced concrete. Scientific Journal of Silesian University of Technology. Series

Transport. 2018, 100,

203-210. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2018.100.17.

Andrzej WIĘCKOWSKI[1]

AUTOMATING THE CONSTRUCTION

OF BUS BAYS WITH REINFORCED CONCRETE

Summary. When renovating

intensively used bus bays, roads and squares, the need for their periodical

closure to traffic during the period of works is inconvenient. In the case of

concrete surface repairs, this timeline is additionally elongated due to the

standard requirement of a 28-day curing period. The Department of

Geomechanics, Civil Engineering and Geotechnics of the AGH University of

Science and Technology has investigated the prototype RoadTronic robot to make slabs reinforced with a

mesh of glass fibre rods. Process automation permits the application of

rapid-setting CSA-based (calcium sulphoaluminate-based) cements, which achieve

a compressive strength of over 20 MPa after just 1.5 h. The good properties of

such cement have been confirmed by several years of use on the runway at

Seattle-Tacoma Airport. Preliminary tests of the early compressive strength of

Rapid Set® CSA-based concrete performed at the department, as well as

calculations of guaranteed strength, indicate that young concrete can transmit

operational load after just 4 h from mixing with water. The investigated

solution assures a complete slab following one passage of the robot. This would

permit the removal of the existing layer during reduced vehicle traffic,

e.g., between 06:00 and 22:00, and the execution of a new abrasive concrete

layer by 02:00, so as to restore regular traffic at 06:00.

Keywords: automation; CSA cement;

bus bays.

1. INTRODUCTION

The applied concrete

laying systems, both in building construction and in road construction, allow

works to be executed with complex automation. The preparation of the concrete

mix, as well as its transport, pumping and compaction, is usually performed

using mechanical devices, with minimized manual labour. This refers to typical

Portland cements. When constructing new facilities, there are usually no

problems in ensuring even a 28-day curing period for such concrete in order to achieve

its standard strength [5]. In the case of refurbishment, however, particularly

in respect of intensively used bus stops and bays, involving severe traffic

disruption, even repairs taking a few days can become a significant nuisance.

Rapid-setting

CSA cements are characterized with high early strengths and allow for load

placement on the new concrete elements after only a few hours of curing [3,6-9,13,15]. An example can be found in the

refurbishment of the runway at Seattle-Tacoma Airport, where aircraft touched

down just 4 h after the completion of concrete works [2].

CSA cement is a mineral

hydraulic binder with rapid early strength build-up (e.g., over 35 MPa after 8

h from reaction with water), small contraction and high resistance to sulphates,

[1,5]. The

main CSA components include anhydrous CSA (4CaO 3Al2O3·SO4),

dicalcium silicate (2CaO·SiO2) and gypsum (CaSO4·2H2O).

When CSA cement is mixed with water, a quick reaction occurs between the

anhydrous CSA, gypsum and calcium hydroxide, involving dynamic heat

generation and intense generation of ettringite, a mineral that causes high

early strength, with full strength guaranteed by the manufacturer after three

to seven days [7,14].

Due

to the immediate setting of CSA cement, specialist (highly efficient) execution

is required. Systemic equipment for concrete works has a limited range of

application. There is a need for mechanical cleaning of all tools every few

minutes - up to 30 min. This

prevents the application of many typical mechanical devices for concrete works,

as well as standard organizational solutions, and usually involves a high share

of manual labour.

The development of

digital control and automatic devices offers great potential with regard to

improvements in the quality of works, particularly in the case of complex

projects. At the same time, humans are relieved from hard physical labour.

State-of-the-art control and automatic devices assure precise execution of all

planned works. Therefore, at the Department

of Geomechanics, Civil Engineering and Geotechnics of the AGH University of

Science and Technology, as part of the research on streamlining construction

processes involving ja-wa technology (Polish: unilateral material application

with travelling automatic device), works were undertaken on the prototype RoadTronic robot for making concrete slabs

reinforced with a mesh of glass fibre rods.

The

proposed solution has a completely different approach to slab execution. With

digital control of particular working assemblies, the robot simultaneously

places the reinforcement mesh and the coating to secure it against water

evaporation, as well as doses components, prepares the concrete mix, transports

it, performs extrusion grouting, compacts it and then forms the surface on the

belt of the element thus formed [16]. The process involves systematic

mechanical cleaning of all surfaces in contact with the setting concrete. Slabs

made using rapid-setting CSA cement are adjusted to high loads from vehicle

traffic (KR 7 traffic category; over 2,001 standard 100-kN calculated axles per

day).

Further

on, we analyse the technology and operation of the prototype RoadTronic robot,

with the presentation of selected properties of young CSA-based concrete, as

well as preliminary test results and calculations of guaranteed strength.

2. EXPERIENCE WITH THE REFURBISHMENT OF THE SEATTLE-TACOMA AIRPORT RUNWAY

Seattle-Tacoma Airport

with 1,200 operations per day (take-offs and touchdowns in total), is the

15th-largest airport in the US. The original 16R/34L runway, with a length of

2,873 m, was constructed as a concrete runway in 1969. An expert study in 1991

indicated the need for the refurbishment of many slabs. It was impossible to

shut the runway down for the time of refurbishment, as this was the only runway

available. Pursuant to a Rapid Set® concrete analysis in respect of

requirements imposed by the Federal Aviation Administration (MD-11 for 20 years

of life, as well as 1,150,000 take-offs and touchdowns), and pursuant to tests

of pilot slabs, it was determined that concrete made on the basis of CSA cement

achieves the necessary strength after 4 h from reaction with water.

A decision was made on

the gradual replacement of the damaged slabs. At 23:00, the runway was shut

down to remove the damaged slabs, adjust the subgrade and make new slabs

(Figure 1). The works had to be completed by 03:00, so that the first plane

could touch down at 06:30. In the period 1994-2005, using a tested technology

and following a detailed work organization schedule, out of 1,892 existing

slabs, the replacement involved 531 slabs (with dimensions of approximately 6x6

m), mainly in the central areas of the runway, which transmitted the highest

loads from planes touching down [2,12].

Fig. 1. Concrete works

at Seattle-Tacoma Airport using a Rapid Set® mix [7]

In August 2012, the

16R/34L runway was closed for refurbishment (this was possible, as an

additional runway had been built). This was an opportunity to carry out

detailed tests in the context of the long life of the CSA-based concrete slabs

exposed to early loads. A total of approximately 30,000 m3 of

original slabs was replaced with new CSA-based slabs, which constituted 79.1%

of the slabs refurbished. Following between seven and 18 years of operation,

only 20 CSA-based slabs proved to be damaged. The failure rate totalled 3.8% vs. the rate of 35.5% for original slabs

based on Portland cement (recalculated for the same operating period).

When the additional runway was constructed in

2010, the 16R/34L

runway underwent a replacement of an

additional 177 slabs, namely, 29.1%, using the “three-day

mix” Portland cement. After three months to two years of operation, 56% of these slabs were damaged, compared to

8% of the Rapid Set® slabs (recalculated for the same operating periods).

This experience points

to the good operational properties of CSA-based concrete, also in the case of

early use, following 4 h from reaction, with full load.

3. ROADTTRONIC TECHNOLOGY FOR MONOLITHIC REINFORCED CONCRETE SLABS

The RoadTronic kit comprises:

- analytical algorithms for control of

particular assemblies, with monitoring of ambient conditions

- chassis with a frame to stabilize

subassemblies

- automatic paver kit

During

the works, appropriate to the changing conditions, especially temperature and

rapid CSA cement-based concrete strength build-up, the control, monitoring and

quality control of the automatic mobile chassis with subassemblies are assured.

In light of the material embedding site and calculation results, with real-time

coordination, the digitally controlled assemblies continuously prepare and

embed materials at strictly defined times, with the necessary production

intensity. Continuous upkeep with embedding times conditions the correct

monolithic properties of concrete. Hence, the control includes the necessary

performance and pressure of mix extrusion, as well as the speed of the chassis

with the assemblies.

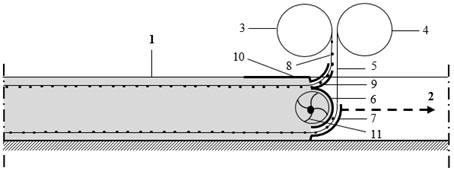

The

chassis frame houses the automatic paver kit (Figure 2), which executes the

slab (1) while continuously moving the works and the entire device in direction

(2).

Fig. 2. Paver kit diagram (see

description in the text)

The robot’s toolkit includes two

unfolding rollers (3 and 4) with a reinforcement mesh of glass fibre rods. Mesh

(5) at the bottom is input from the front, between the paver casing (6) and the

front guide (7), which, due to its form, assures a mesh distance (reinforcement

cover) from the bottom of the slab that is formed. The other mesh (8), at the

top, is input over the paver casing (6) with a guide (9) under the top disc

(10), which assures correct mesh placement vs. the surface of the slab formed.

Together with the entire robot movement in direction (2), and successive

placement of the reinforcement mesh, water is added to the concrete mix and

spread on the entire slab width, with extrusion grouting and compaction with

feeder blades (11). Top disc (10), with a greater width than the impact of the

extrusion pressure and compaction of the fresh mix, forms and smoothens the top

surface of the slab. As a result, the entire slab is completely executed in one

pass of the robot.

Rapid-setting CSA cement causes the need for frequent

mechanical cleaning of the tools and equipment, usually not less frequently

than between a few minutes and half an hour. This issue has also been solved by

the RoadTronic technology owing to

continuously moving elements, which assure permanent cleaning of all surfaces

in contact with the concrete mix

4. CSA CEMENTS AND WORKS

EXECUTION

CSA

cements are manufactured with grades 42.5, 52.5, 62.5, 72.5, 82.5 and 92.5 (in

this case, the values indicate compressive strength values achieved after seven

days). CSA cements, which are stored in dry places in sealed packaging, have a

shelf life of 12 months. Major manufacturers of rapid-setting cements are

located in the US and China.

It must

be pointed out that obtaining CSA in the reaction requires full hydration,

which occurs with minimum

water/cement proportions of w/c >0.36 [15]. In proportions of w/c

≤ 0.61, 100% of the water reacts with the CSA cement. Aggregates are

composed on similar terms as in Portland cements, whereas the minimum CSA

volume totals 300 kg/m3 of concrete mix [3,8].

In

order to achieve the intended strength parameters, CSA concrete must be

prepared and embedded at outdoor temperatures within the range between 7°C and

32°C (at

lower temperatures, the setting process occurs at a much slower rate, while, at

higher temperatures, with additional hydration heat, ettringite may become

decomposed). At a temperature of 20°C, setting occurs after only 15 min or up to several

minutes later [3]. With citric acid used as a retardant, the onset of the

setting time can be postponed by 15 min.

CSA

cements are principally applied in necessary short-term repairs and urgent

works.

The onset of CSA cement setting, occurring usually

after several minutes, requires the execution of non-standard works, as the

processes of setting and curing occur almost immediately following the addition

of water. Hence, concrete teams must be appropriately trained

and provided with the suggested equipment. They must execute works according to a strictly defined organization of

works. Concrete must not be vibrated after it has started to set and the

surface must be secured against evaporation. During the works, tools must be

systematically cleaned, usually not less frequently than every 30 min. The mixers and other equipment used must

also be mechanically cleaned at similar time intervals.

5. VARIABILITY OF CONCRETE COMPRESSIVE STRENGTH DURING

THE CURING PERIOD

Concrete strength with time depends on the type of

cement, temperature and curing conditions [4]. At an average temperature of

20°C and curing according to EN 12390 [10], pursuant to EC2 [4], it can be

assumed that the characteristic concrete compressive strength fck(t) at age t totals:

(1)

fck(t) = fcm(t) - 8MPa for 3 < t < 28 days.

According to EC2 [4], more precise values,

particularly with t ≤3 days,

must be specified pursuant to tests. In turn, average concrete compressive

strength depending on the age can be estimated according to the following

equation:

(2)

fcm(t) = βcc(t)

fcm,

(3)

βcc(t)

= exp

![]() ,

,

fcm(t) - average concrete compressive strength at the age

of t days

fcm - average concrete compressive strength after 28

days

βcc(t) -

coefficient depending on the concrete age

t - concrete age in days

s -

coefficient depending on the cement type.

In the case of the application of CSA cements, where

fresh concrete in the ceiling needs to be immediately deprived of formwork, the

ja-wa system already requires information on the characteristic

concrete compressive strength fck(t) at the age of t ≥1.5 h.

When

analysing the strength of the samples tested (three samples each, on nine

occasions, from 1.5 h up to seven days, at the aforementioned laboratory of the

Department of Geomechanics, Civil Engineering and Geotechnics of the AGH

University of Science and Technology), major differences in the results, with a

standard deviation of s = 1.38,

occurred for samples with a concrete age of 8 h (from mixing the components

with water). The average strength of three samples totalled fcm(8h) = 31.5

MPa. A t-Student test was applied to

check whether the EC2 condition [4], in the case of 95% of samples in the lot

achieving the characteristic strength, was met. For samples with strength d = 4

MPa lower than average fcm(8h),

the test statistic value tobl = ![]() , following substitution totals tobl =

4.099, which is higher than the t-Student

distribution quantile of t(0.95,

2) = 2.920. Therefore, the following assumption was adopted:

, following substitution totals tobl =

4.099, which is higher than the t-Student

distribution quantile of t(0.95,

2) = 2.920. Therefore, the following assumption was adopted:

(4)

fck(t) = fcm(t) - 4 MPa, for 1.5 h ≤ t ≤ 168 h.

Pursuant to the results of the sample strength tests

(at times with 1.5-h intervals up to several days, Table 2), the function of

average compressive strength was defined for concrete based on CSA cement

depending on concrete age t, according

to:

(5)

fcm(t)CSA = fcm(168) {1 - [a(t)]0,074} - 1,

for 1.5 h ≤ t ≤

168 h,

fcm(t) - average concrete compressive strength at the age

of t h (hours)

fcm(168) - average concrete compressive strength after 168 h

(seven days)

a(t) - coefficient depending on concrete age, a(t)

= 168/t (t - analysed

concrete age from mixing dry components with water, in h)

Table 1 present the results for fresh CSA-based

concrete compressive strength determined in the tests, as well as calculated

results pursuant to Equations (4) and (5).

Table 1

Strength values for Rapid Set®

fresh concrete pursuant to tests and calculated according to Equations (4) and

(5)

|

Test of concrete aged t, h |

1.5 |

2 |

3 |

4 |

8 |

24 |

48 |

72 |

168 |

|

Average strength from tests fcm, MPa |

24.9 |

27.3 |

29.9 |

31.5 |

35.1 |

37.9 |

40.2 |

41.5 |

44.3 |

|

Average strength, according to

(4) fcm(t), MPa |

24.8 |

26.1 |

27.9 |

29.2 |

32.1 |

36.4 |

39.0 |

40.4 |

43.3 |

|

Characteristic strength values,

according to (5) fck(t), MPa |

20.8 |

22.1 |

23.9 |

25.2 |

28.1 |

32.4 |

35.0 |

36.4 |

39.3 |

According

to Table 1, average compressive strength values fcm(t), calculated pursuant to Equation (4),

are lower than the strength of analysed samples fc(t)

in all cases of analysed t values.

Similarly, characteristic values fck(t),

calculated pursuant to Equation (5), meet the condition that at least 95% of

samples of the analysed lot achieved such strength. Hence, characteristic

values fck(t)

were defined, pursuant to Equation (5).

According

to the Annex to Regulation no. 30 of GDDKiA of 16 June 2014, Table 9.4, for KR

7, the typical structure of the top

layer of a rigid surface must have thickness of 29 cm (for core subgrade: mix

with hydraulic binder C5/6, C8/10). According to Eurocode 2, for a

(non-reinforced) C20/25 slab,

which is 3x3 m and 30 cm thick, on C8/10 subgrade and with a load of 100 kN,

the maximum strength totals 24 kNm/m, while cracking occurs at 30.9 kNm/m.

Despite meeting the requirement for the cracking moment, in the RoadTronic

solution, the slab features additional reinforcement at the top and at the

bottom.

6. CONCULSIONS

The RoadTronic technology for constructing the top

layers of rigid surfaces with mesh reinforcement envisages numerical control of

an integrated assembly of robot machinery in charge of the following:

intermediate storage of materials, placement of a reinforcement mesh of glass

fibre rods at the bottom and at the top, component dosing, mixing, transport,

extrusion grouting, and compaction of the concrete mix, with slab formation.

Owing to the precise operation of the robot, it is

possible to apply the CSA-based concrete, which, after mixing with water, is

characterized as follows:

·

very short time

to the onset of cement setting (approximately 0.2 to 0.5 h)

·

then, immediate

concrete hardening with rapid increments in its early strength, e.g.,

compressive strength fcm -

average test values were over 24 MPa, 31 MPa and 44 MPa, respectively, after

1.5 h, 4 h, and 168 h, while characteristic values fck(t), calculated according to the proposed equations

totalled, respectively, 20.9 MPa, 25.2 MPa, and 39.3 MPa

·

concrete slab

achieving Condition I, permitting operational loads after 4 h, while, for

Condition II, full bearing strength is achieved after 168 h

The characteristics of the RoadTronic technology

include:

·

predisposition

for bus bay repairs during low-intensity traffic at night (between 18:00 and

02:00), so as to restore normal traffic at 06:00

·

liberating

workers of hard physical labour under difficult conditions

·

![]()

![]()

![]() controlling the execution of timely works for each

concrete mix portion regarding the latest embedding time, by controlling

preparation capacity, material embedding and the speed functions of the

robot’s movements

controlling the execution of timely works for each

concrete mix portion regarding the latest embedding time, by controlling

preparation capacity, material embedding and the speed functions of the

robot’s movements

References

1.

ASTM C 845-96. Standard Specification for Expansive

Hydraulic Cement.

2.

Bescher E., Ramseyer C. 2013. Seattle-Tacoma Airport Concrete

Rehabilitation Performance Review.

Oklahoma.

3.

CTS

Cement - Rapid Set Construction Cement.

4.

EN

1992-1-1:2004/A1 Eurocode 2: Design of Concrete Structures - Part 1-1: General

Rules and Rules for Buildings.

5.

Jamroży Z. 2015. Beton

i jego technologie. [In

Polish: Concrete and Its Technologies.]

Warsaw: PWN.

6.

Klein

A. Expansive and Shrinkage-compensated

Cements. Patent US3,251701.

7.

Korodur

International GmbH. Product Information.

8.

Kurdowski W. 2010. Chemia cementu i betonu. [In

Polish: The Chemistry of Cement and

Concrete.] Cracow: Association of Cement

Producers.

9.

Neville A.M. 2012. Właściwości

betonu. [In

Polish: The Properties of Concrete.] Cracow: Association of Cement

Producers.

10.

PN-EN 12390-1 Beton.

Część 1: Kształt, wymiary i inne wymagania dotyczące

próbek do badania i form. [In Polish: PN-EN 12390-1 Concrete. Part 1: The Shape, Dimensions and Other

Requirements of Samples and Forms.]

11.

PN-EN 206-04:2014 Beton. Wymagania, właściwości,

produkcja i zgodność. [In Polish:

PN-EN 206-04:2014 Concrete. Requirements, Properties, Production,

Compatibility.]

12.

Dell’Acqua

G., M. De Luca, C.G. Prato, O. Prentkovskis, R. Junevicius. 2016. “The impact

of vehicle movement on exploitation parameters of roads and runways: a short

review of the special issue”. Transport

31(2) Special Issue: 127-132.

13.

Zima

B., M. Rucka. 2016. “Detection of debonding in steel bars embedded in

concrete using guided wave propagation”. Diagnostyka 17(3): 27-34.

14.

Gąska

Damian, Tomasz Haniszewski, Jerzy Margielewicz. 2017. “I-beam girders dimensioning with

numerical modelling of local stresses in wheel-supporting flanges”. Mechanika 23(3): 347-352. ISSN

1392-1207.

15.

Štemberk

Petr, Michaela Frantova, Martin Petrik. 2017. “Evaluation of early-age

performance of reinforced concrete pile cap”. Mechanika 23(30). DOI: http://dx.doi.org/10.5755/j01.mech.23.3.18479.

ISSN 1392-1207.

16.

Kmita

A., J. Zych, M. Holtzer, J. Mocek, S. Piasny. 2016. “Ecological water-based protective coatings for moulds and cores of iron

castings”. Metalurgija 55(4): 589-592.

Received 18.03.2018; accepted in revised form 21.08.2018

![]()

Scientific

Journal of Silesian University of Technology. Series Transport is licensed

under a Creative Commons Attribution 4.0 International License