Article citation information:

Jasiński, R., Pielecha, J. Evaluation of the impact of oil presence in

the aviation fuel on particle size distribution. Scientific Journal of Silesian University of Technology. Series

Transport. 2017, 94, 57-64. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2017.94.6.

Remigiusz JASIŃSKI[1],

Jacek PIELECHA[2]

EVALUATION OF THE

IMPACT OF OIL PRESENCE IN THE AVIATION FUEL ON PARTICLE SIZE DISTRIBUTION

Summary.

Emissions from aircraft engines represent a highly complex and important issue,

which is related to the risk to human health. Particles emitted in urban areas

and in the vicinity of airports affect air quality and have a particularly

negative impact on airport workers. The development of measurement techniques

and the methodology for evaluating exhaust emissions have allowed for the

elaboration of appropriate procedures for the certification of aircraft and the

enhancement of existing standards. Particulate matter emissions depend, among

other things, on the composition of the fuel used and its additives. Some

aircraft engine designs require a fuel additive in the form of oil, which

ensures the proper operation of the fuel supply system. This article presents

the results of studies conducted on jet engines powered by clean aviation fuel

and fuel with the addition of oil. The aim of the study was to evaluate the

effect of the addition of oil on the size distribution and concentration of

emitted particles. It was found that, for small values of thrust, oil additive

increases the concentration of particles. With an increase in the thrust force,

the reduction of particles concentration was recorded in the case of the engine

powered by fuel with oil additive. There was no significant effect of oil

additive on the size distribution of emitted particles.

Keywords:

aviation engines, particles, fuel additives

1. INTRODUCTION

As a result of the high speed and

intercontinental range of aircraft, air transport has become a major part of

the global transport system [9]. For many years, there has been a strong

correlation between the rate of growth in the largest global economies and the

development of air services [10]. Comparing the growth of gross domestic

product around the world and air traffic, it can be seen that the growth rate

of air transport is greater than the growth of the global economy. According to

an analysis of the largest manufacturers of aircraft (Airbus and Boeing), the

growth in aviation in the near future will be much more dynamic than the

world’s economies. This is because of the dynamic development of low-cost

carriers, increasing the capacity of the aircraft, the introduction of new

fleet and the dynamic growth in emerging markets, such as China, India and

Japan [3]. By 2020, according to forecasts, the market in the Far East will

enjoy the highest growth in world traffic (by 31%). The rapid development of

the Asian market will represent 27% of global air transport conducted in Asia

[3].

The development of air transport is

associated with increased external environmental costs, which, in accordance

with EU definitions, include the impact of the air transport in terms of, inter

alia, air pollution, climate change and noise [4]. These negative effects are

due to the increasing volume of air traffic, as well as associated

infrastructure expansion. Aviation infrastructure is associated with the

occupation of large areas and has a crucial impact on the environment. The

inherent aspect of the functioning of an airport is the handling of air

traffic, which is associated with magnetic radiation and the possibility of

aircraft collisions with animals. Another negative effect of air traffic is air

pollution and its impact on greenhouse effects. According to the European

Environment Agency, air transport only accounts for a 0.5% share of total

emissions of nitrogen oxides and only 0.1% in emissions of non-methane organic

compounds. That said, its impact, particularly on air quality in areas adjacent

to airports, affects the composition of the atmosphere in the upper layers,

where air transport is the only source of pollution. In turn, this negatively

affects the atmosphere on a global scale and contributes to climate change and

ozone layer impoverishment [2].

The various efforts to reduce toxic

emissions are in response to the deterioration of atmospheric air quality,

particularly in urban areas. Currently, one of the biggest problems concerning

air quality in urban areas is the increased concentration of particulate matter

[7, 8], resulting in a reduction of visibility in the form of smog, which also

brings negative effects on human health appearing in the form of heart and lung

disease [5].While the EU has taken legislative measures focused on reducing the

emissions of harmful compounds from automotive vehicles, much more attention

needs to be paid, especially by the scientific community, on exhaust emissions

from aircraft engines.

One of the fundamental issues in the assessment of air quality is the

concentration of particulate matter. The term “particulate matter” describes a

type of air pollutant, consisting of different particle mixtures, which differ

in size, composition and formation. There are many sources of particulate

matter, such as factories, power plants and vehicles. The basic division of

solid particles, due to their aerodynamic diameter, has allowed for the

determination of two main groups, PM2.5 and PM10, which respectively refer to

particulate matter with a diameter of less than 2.5 µm and 10 µm.

In recent years, attention has been increasingly paid to the emissions

from areas around airports, due to the rapid increase in air traffic volume and

the growing demand for air transport in the coming years. Most of the research

and publications in this area offer an inadequate explanation of the phenomena,

which are the subject of intensive research because, as the literature shows,

air transport emissions can significantly affect the quality of the air in the

vicinity of airports [1, 6].

In terms of particle emissions, the chemical composition of the fuel is

very important. Fuel for Jet A-1 turbine aircraft engines is produced from

components obtained under a specific regime involving the technological

processes of hydrodesulphurization, hydrocracking and distillation. The

components meet the established quality requirements. The fuel contains many

additives (antioxidant and antistatic). The use of oil additive in the fuel is

common in military and civil aviation in order to ensure the proper

thermodynamic phenomena and friction. To date, the influence of additives in

aviation fuel on particulate emissions is remains an unexplored issue.

2. OBJECTIVE AND METHODOLOGY

2.1. Purpose of the research

The aim of the study was to determine the size distribution of particles

emitted by the GTM-120 jet engine, powered by Jet A-1 and Jet A-1 aviation fuel

with a 3% addition of Mobil Jet Oil II.

Mobil Jet Oil II is a high-quality

lubricant designed for aircraft gas turbines, based on a combination of a

highly stable synthetic oil base and a unique additive package. This combination

provides thermal and oxidation stability in order to counteract deterioration

and deposit formation in both phases for both liquid and gas, as well as

provide resistance to foaming. The effective range of oil operation is at

temperatures between -40°C and 204°C.

Mobil Jet Oil II is designed for

aircraft turbine engines used in commercial and military service requiring high

performance. It was developed to meet the high requirements of aircraft gas

turbines, operated in a wide range of difficult operating conditions. The

product has a high specific heat in order to ensure a good heat conduction from

oil-cooled parts of the engine. According to extensive laboratory testing and

the verification of performance during flights, oil stability can be observed

at temperatures up to 204°C. At the same time, the evaporation rate at this

temperature is low enough to prevent excessive fluid loss.

Determination of the size

distribution of particles based on the used fuel mixture allowed for the effect

of oil on the emission of a jet engine to be determined. Measurements were

carried out under laboratory conditions on a prepared test stand.

2.2. Test object and measurement

equipment

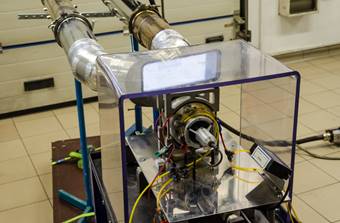

The object of the study was the GTM-120 turbine

engine (Fig. 1), constructed of a single-stage radial compressor and driven by

a single-stage axial turbine. The test stand with the engine allows for the

measurement of the shaft speed, exhaust gas temperature at the nozzle, thrust,

and exhaust gas mass flow. Particle size distributions were measured at six

points, including in terms of minimum and maximum thrust values. The

measurements were performed twice, once for each fuel mixture used.

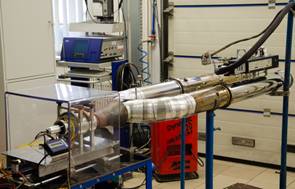

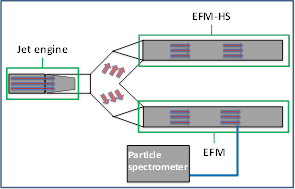

For measuring the size distribution of

particles, a TSI Incorporated - EEPS 3090™ mass spectrometer was used, which

enabled the measurement of a discrete particle diameter range (from 5.6 nm to

560 nm) on the basis of their different speeds. The scope of the electric

mobility of the particle matter was exponentially changed, with the particles’

size measured at a frequency of 10 Hz.

Fig. 1. View of the GTM-120 engine

The initial filter retains particles with a

diameter greater than 1 μm and thus are outside the measuring range of the

device. After passing through the neutralizer, the particles are directed to

the charging electrode; after being electrically charged, they can be classed

by their size. The particles deflected by the high-voltage electrode go to an

annular slit, which is the space between the two cylinders. The gap is

surrounded by a stream of clean air supplied from outside. An exhaust cylinder

is built into a stack of sensitive electrodes isolated from one another and

arranged in a ring. The electric field that is present between the cylinders

causes the repulsion of particles from the positively charged electrode; the

particles are then collected on the outer electrodes. When striking the

electrodes, the particles generate an electric current, which is read by a

processing circuit. An exhaust flow meter (EFM) with a diameter of 125 mm and a

high-speed EFM (EFM-HS) flowmeter characterized by a sampling frequency of 2500

Hz were used. The engine workbench and its schematic are shown in Figure 2.

a) b)

Fig. 2. View of a) the

engine workbench and b) its schematic

3. MEASUREMENT RESULTS

AND THEIR ANALYSIS

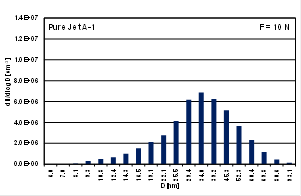

Diametrical

distributions of particles emitted by the GTM-120 engine turbine were

determined using an apparatus for measuring particulate emissions from

combustion engines. Figures 3-8 present the measurement results for each level

of engine thrust.

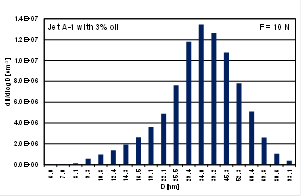

In the case of an engine powered by

pure Jet A-1 fuel at minimum value of engine thrust (10 N), particles with a

diameter of 30-45 nm dominated (Fig. 3a). The characteristic value of particle

diametrical distribution obtained from the measurements was 35 nm. There were

no emissions of particles with a diameter greater than 100 nm. The diametrical

distribution of particles emitted in the case of an engine supplied with oil

additive (Fig. 3b) was similar to the distribution obtained when the engine was

fuelled with clean Jet A-1 fuel. The main difference was a twofold increase in

the concentration of particulate matter resulting from the use of oil as a fuel

additive.

a) b)

Fig. 3. Dimensional

distribution of particulate matter corresponding to 10 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

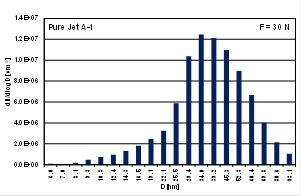

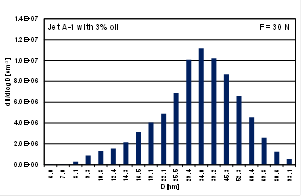

The

obtained diametrical distributions of particulate matter for the engine fuelled

with Jet A-1 and operated at 25% of maximum thrust were dominated by small

particles with a diameter of 30-50 nm (Fig. 4a). There were no emissions of

particulates with a diameter greater than

100 nm. No significant effect was observed of the addition of oil on

dimensional distribution or concentration of particles emitted.

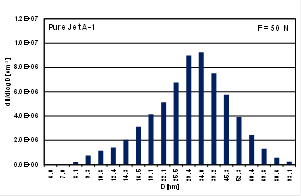

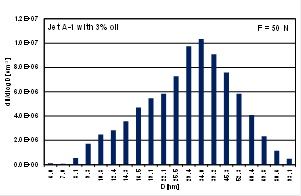

The

obtained diametrical distributions of particulate matter for the engine fuelled

with Jet A-1 and operated at a medium level of engine load (Figs. 5-6) were

dominated by small particles with a diameter of 25-40 nm. There was no emission

of particulates with a diameter greater than 100 nm. The addition of oil to the

Jet A-1 fuel caused an almost twofold reduction in the concentration of

particulate matter in the exhaust of the jet engine (Fig. 6).

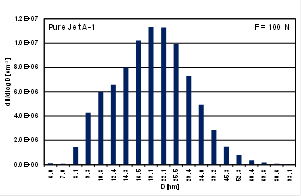

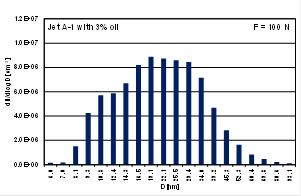

Increasing

the level of engine load for the engine fuelled with Jet A-1 to 80-100%

resulted in a reduction of the diameter of the particles emitted (Figs. 7-8).

Emissions were dominated by particles with the smallest diameters, from 15 nm

to 25 nm. The use of oil additive resulted in no change in the size distribution

of particles compared to the distribution obtained for the particles emitted

from an engine supplied with clean jet fuel. It was found that using oil

additive causes a slight reduction in particulate matter concentration.

a) b)

Fig. 4. Dimensional

distribution of particulate matter corresponding to 30 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

a) b)

Fig. 5. Dimensional

distribution of particulate matter corresponding to 50 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

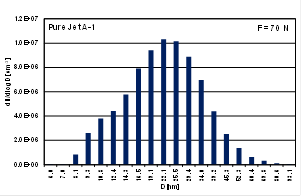

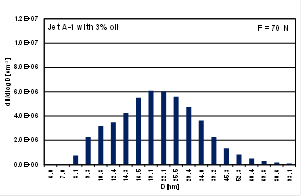

a) b)

Fig. 6. Dimensional

distribution of particulate matter corresponding to 70 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

a) b)

Fig. 7. Dimensional

distribution of particulate matter corresponding to 100 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

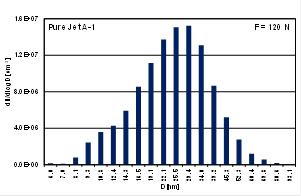

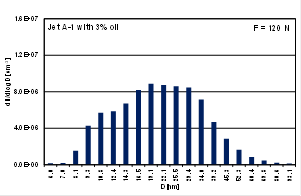

a) b)

Fig. 8. Dimensional

distribution of particulate matter corresponding to 120 N

of a jet engine

powered by a) pure Jet A-1 or b) a blend with oil

4. CONCLUSIONS

In order to

consider the effects of the addition of oil to fuel on the intensity of the

emissions of particle matter, proper measurements were performed on the GTM-120

jet engine, powered with pure kerosene (Jet A-1) fuel and its blend with oil

(Mobil Jet Oil II). The presence of oil in the fuel resulted in a change in the

concentration of particles emitted by the turbine engine in relation to the

distributions recorded when using the Jet A-1 fuel without additives. In the

case of the minimum level of thrust, oil additive causes an increase in the

concentration of particulate matter compared to an engine powered by clean Jet

A-1 fuel. There were no significant changes in the size distribution of

particles emitted from the jet engine due to the use of oil additive.

Increasing turbine engine thrust resulted in a particle concentration decrease

for the engine fuelled with the oil additive. It was noticed that using oil

additive causes a significant reduction in the number of emitted particulates

for an engine operating at medium and high load levels. In the full range of

measurements, the addition of oil did not result in significant changes in the

size distribution of emitted particles.

References

1.

Amato Fulvio, Teresa Moreno, Marco Pandolfi. 2010. “Concentrations,

sources and geochemistry of airborne particulate matter at a major European

airport”. Journal of Environmental

Monitoring, Vol. 12: 854-862.

2.

Badyda Artur Jerzy. 2010. “Environmental risks from transport”. Nauka, Vol. 4: 115-125. ISSN: 1231-8515.

3.

Boeing Commercial Airplanes. 2013. Current

Market Outlook 2014-2033. Seattle, WA: Boeing Commercial Airplanes.

4.

Huderek-Glapska Sonia. 2014. “External costs of air transport”. Logistyka, Vol. 2:

97-105.

5.

Hyslop Nicole Pauly. 2009. “Impaired visibility: the air pollution

people see”. Atmospheric Environment,

Vol. 43: 182-195.

6.

Lee David, Giovanni Pitari, Volker Grewe et al. 2010. “Transport impacts

on atmosphere and climate: aviation”. Atmospheric

Environment, Vol. 44: 4678-4734.

7.

Masiol Mauro, Roy Harrison. 2014. “Aircraft engine exhaust emissions and

other airport-related contributions to ambient air pollution: a review”. Atmospheric Environment, Vol. 95:

409-455.

8.

Mickevičius Tomas, Stasys Slavinskas, Raimondas Kreivaitis. 2015.

“Effect of ethanol on performance and durability of a diesel common rail high

pressure fuel pump”. Transport, Vol.

31, Issue 3: 305-311. http://dx.doi.org/10.3846/16484142.2015.1058292. ISSN:

1648-4142.

9.

Tłoczyński

Dariusz. 2015. “The financial standing and

prospects of the development of the world air transport”. Logistyka, Vol. 3: 4859-4869.

10.

Tłoczyński Dariusz. 2013. “Trends of air transport”. Zeszyty Naukowe Wydziałowe Uniwersytetu

Ekonomicznego w Katowicach, Vol. 143: 381-398. ISSN: 2083-8611.

Received 07.12.2016;

accepted in revised form 29.02.2017

![]()

Scientific Journal of Silesian University of

Technology. Series Transport is licensed under a Creative Commons

Attribution 4.0 International License